Back plate, backlight module and display device

A technology for backlight modules and display devices, which is applied to lighting devices, fixed lighting devices, lighting auxiliary devices, etc., can solve the problems of thick wall thickness, affecting the development trend of narrow frame of backlight modules, and difficulty in narrow frame design, etc., and achieves rigidity. The effect of mass reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

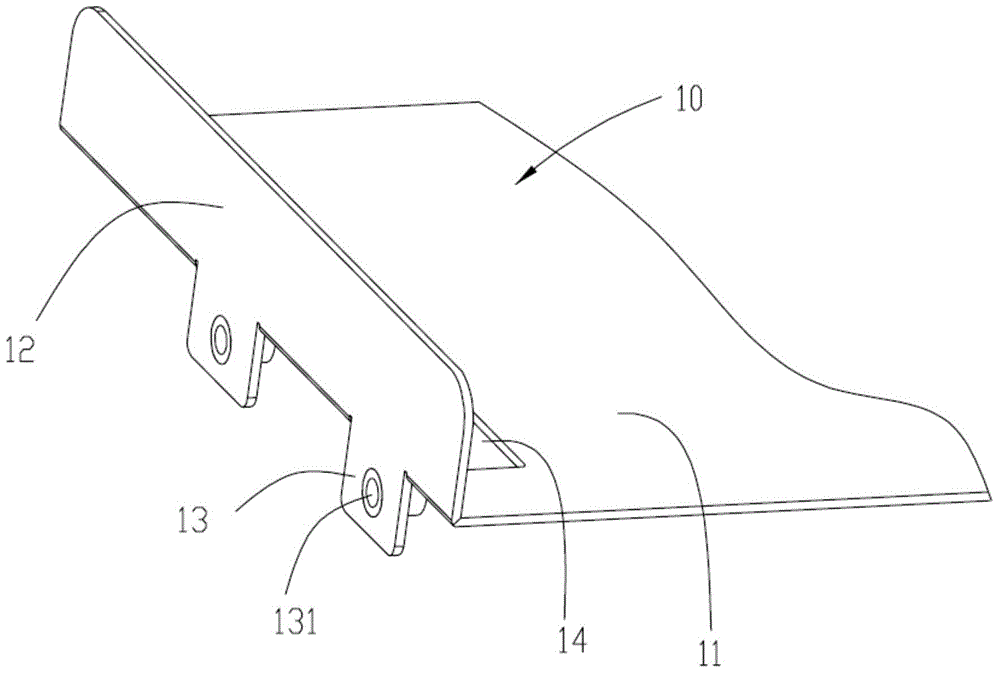

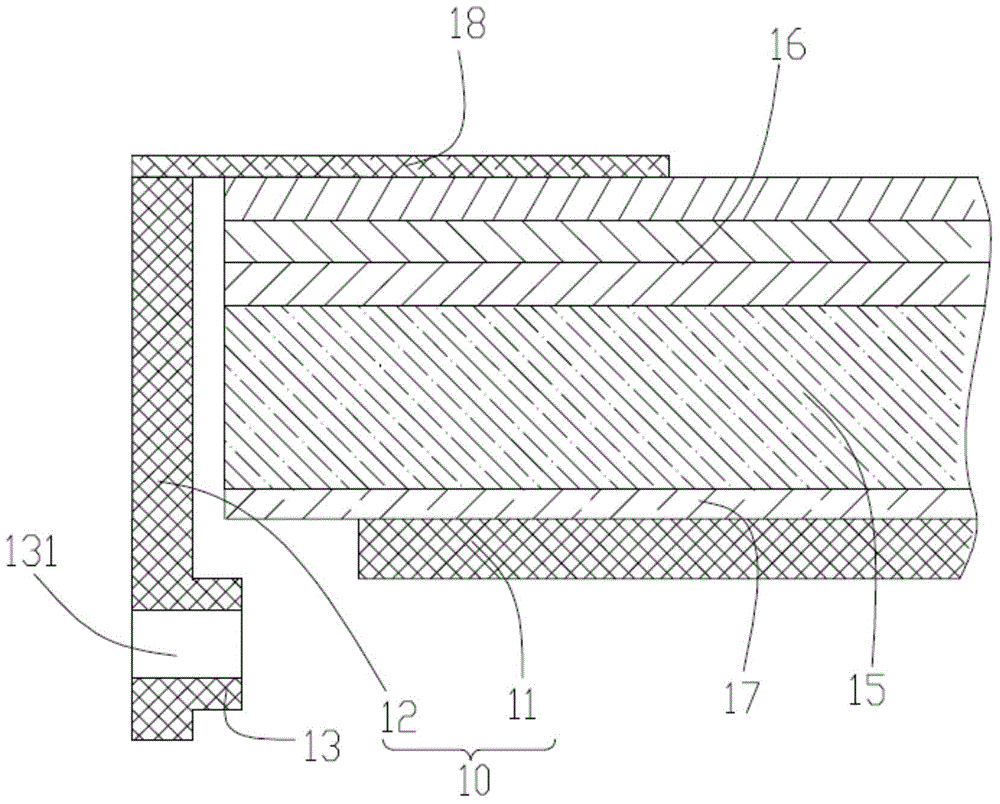

[0023] see figure 1 , the preferred embodiment of the present invention provides a backplane and a backlight module having the backplane. The backplane is used to carry elements such as the light guide plate of the backlight module. The back panel 10 includes a bottom panel 11 and side panels 12 formed by bending edges of the bottom panel 11 . The connection between the side plate 12 and the bottom plate 11 is provided with several positioning pieces 13 at intervals, and the positioning pieces 13 are located on the same side of the bottom plate 11 as the side plate 12 and opposite to the extension direction of the side plate 12 .

[0024] In this embodiment, the backboard 10 is formed by cutting a metal plate. The bottom plate 11 is a rectangular plate body. The side panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com