Air tightness detecting device of air compressor crankcase

A technology of air tightness detection and crankcase, which is applied in the direction of pump testing, mechanical equipment, machine/engine, etc., can solve problems such as false detection, difficult detection of crankcase, complex structure of crankcase, etc., and achieve simple operation and fast detection speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

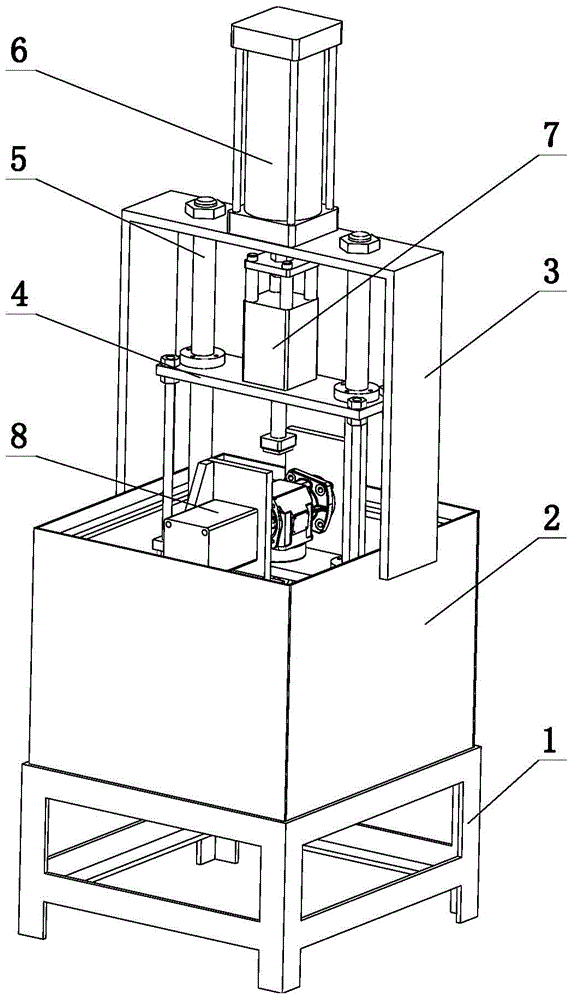

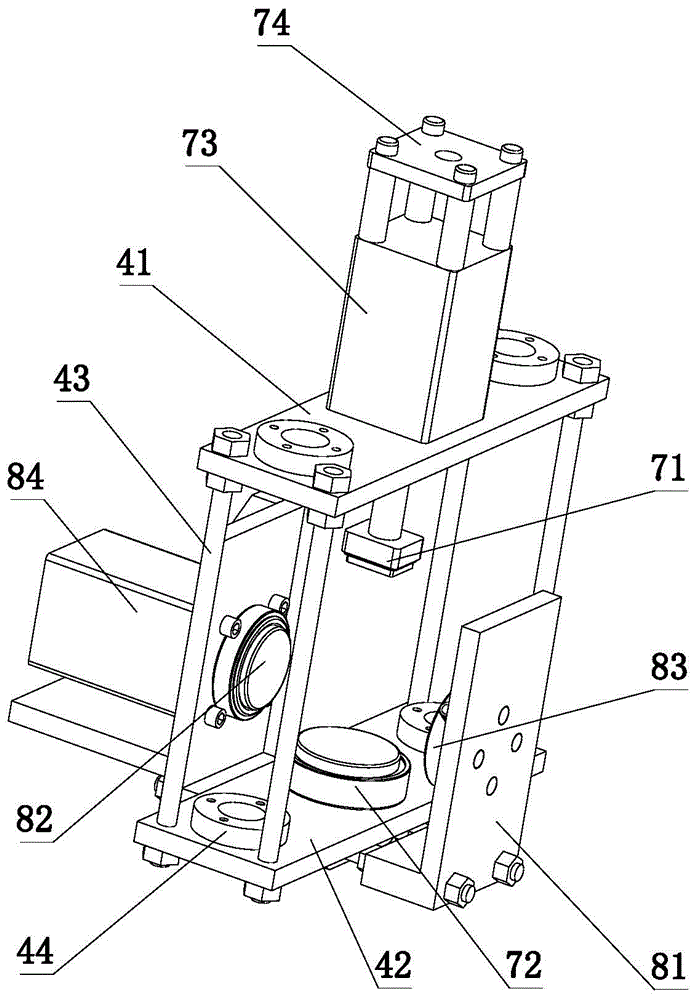

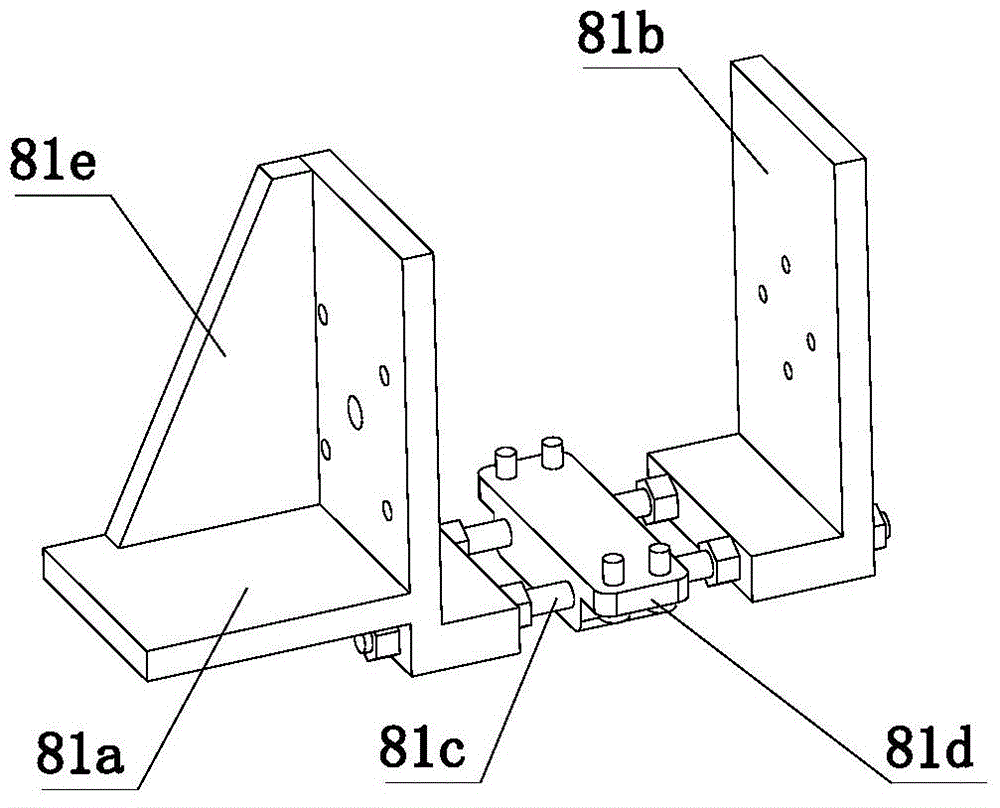

[0019] refer to Figure 1 ~ Figure 3 The shown air tightness detection device for a crankcase of an air compressor includes a base 1, a water tank 2, a vertical lifter and a crankcase seal assembly, the water tank 2 is placed on the base 1, and the The vertical lifter is installed on the water tank 2 through a support frame 3; the vertical lifter includes a lifting platform 4, a vertical guide column 5 and a lifting driver 6; the crankcase sealing assembly is installed on the lifting platform 4 above; the crankcase seal assembly includes a vertical end cover group that moves relatively in the vertical direction and a horizontal end cover group that moves relatively in the horizontal direction; the horizontal end cover group is provided with air intake holes and intake pipe joints .

[0020] Both ends of the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com