Hydrofoil

A technology of hydrofoil and rear wing, applied in the field of hydrofoil, can solve the problems of large size, achieve wear-resistant connection, facilitate air transportation, and be easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing, the present invention is described in further detail with specific embodiment, as follows:

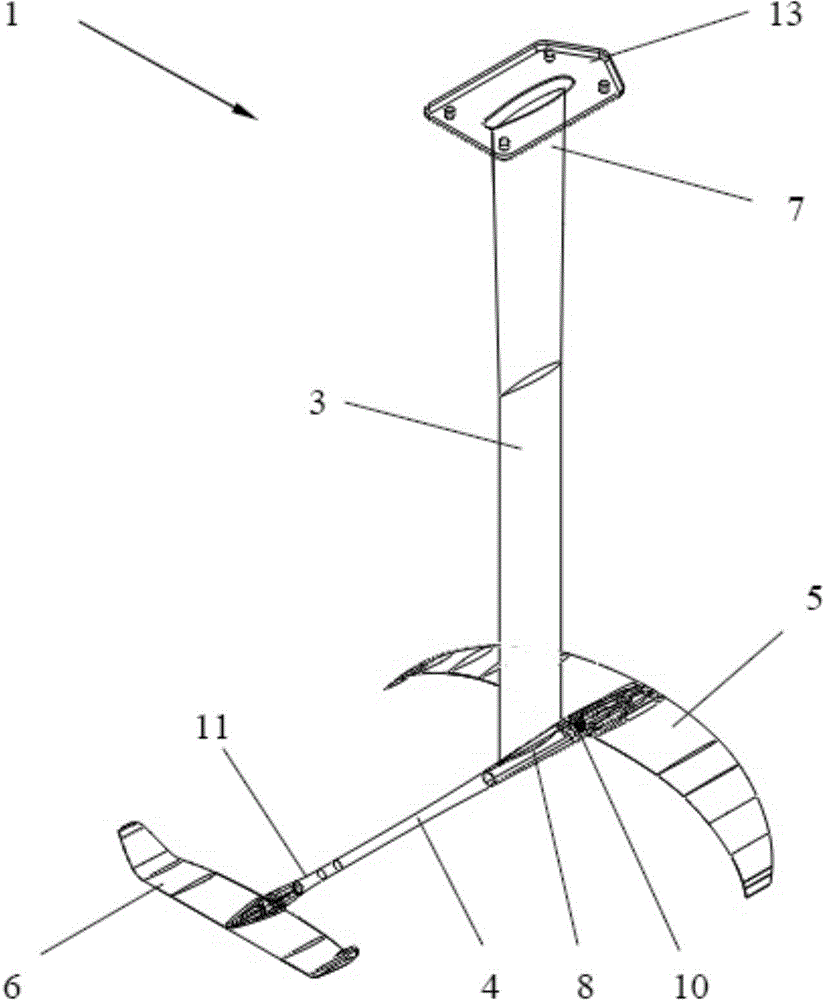

[0037] figure 1 In the illustrated embodiment, one is secured to a surfboard (board) 2 suitable for kitesurfing and wakeboarding (see Figure 7 ) on hydrofoil 1.

[0038] Said hydrofoil 1 comprises keel ribs 3 , also sometimes referred to as masts or struts, connecting rods 4 , ie fuselage, front wings 5 , and rear wings 6 . These parts are connected to each other through standard interfaces, therefore, these parts can be replaced individually. The result is a modular system that can be flexibly adapted to different purposes.

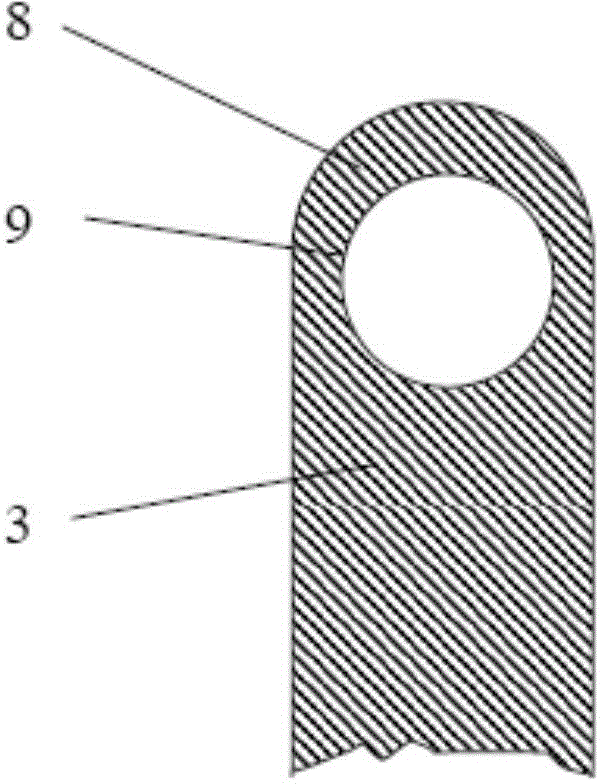

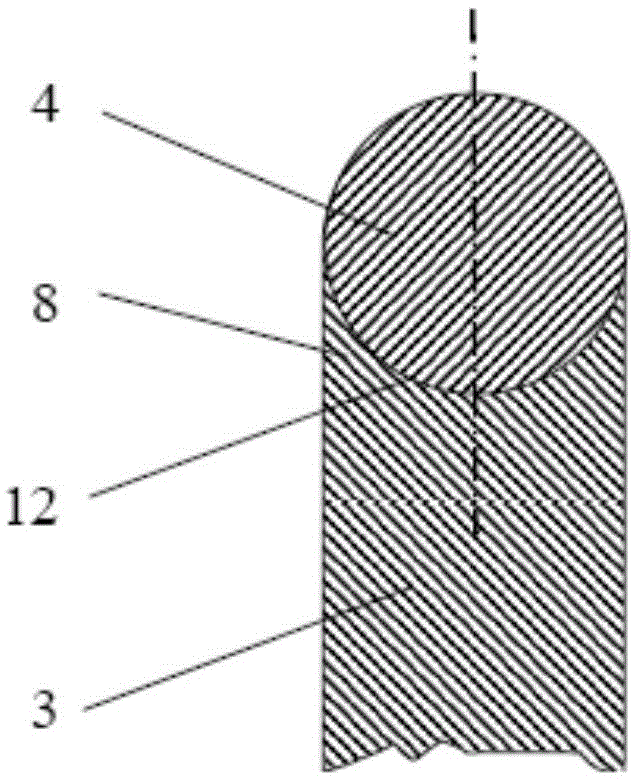

[0039] The keel rib 3 has a first end 7 for fixing to a board 2 and a second end 8 for connecting a connecting rod 4 . The height of the keel rib 3 is preferably about 700 to 1000 mm, the thickness is about 10 to 30 mm, and the length in the moving direction is about 80 to 150 mm. The keel ribs 3 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com