Composite material grid production apparatus

A technology for production equipment and composite materials, which is applied in the field of production equipment for composite grids, and can solve the problems of high production cost and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

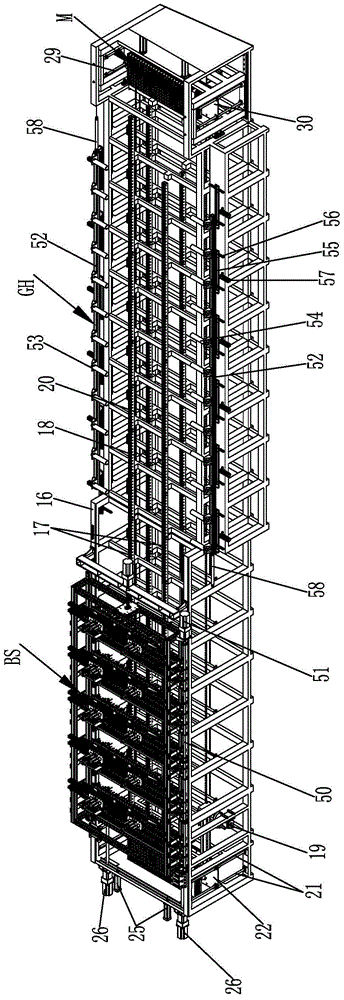

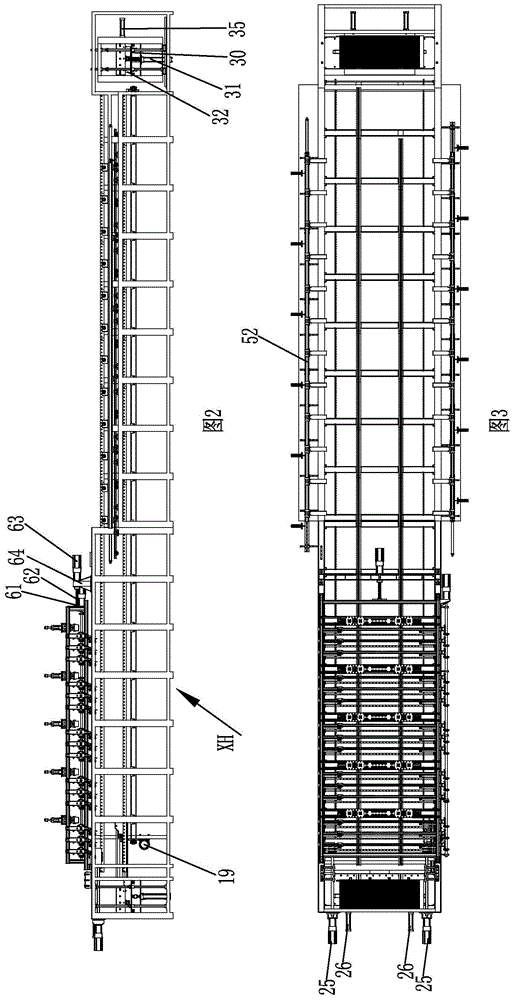

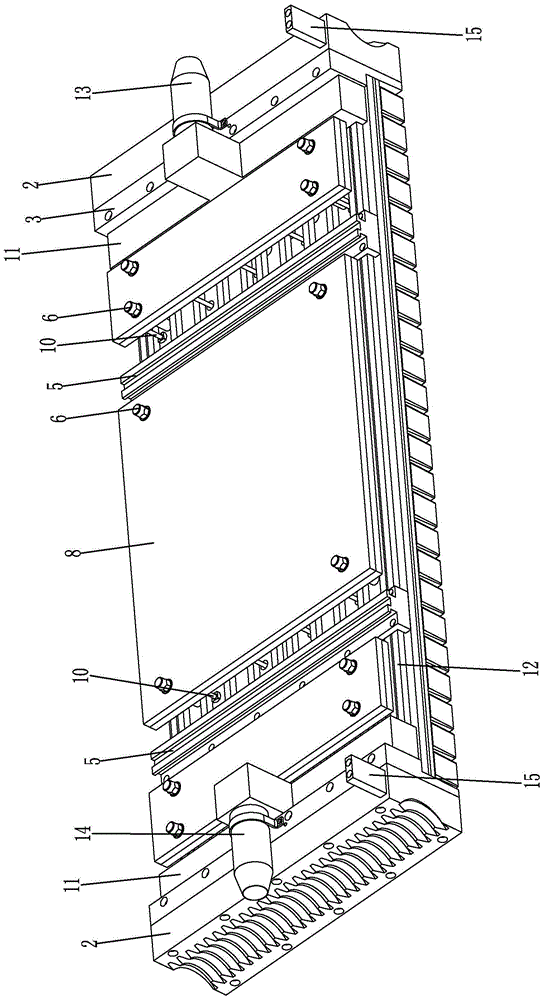

[0050] Such as Figures 1 to 14 As shown, a composite grid production equipment is mainly composed of a mold M, a mold circulation device XH, a yarn cloth device BS and a curing device GH. refer to Figures 1 to 6 , The mold M is mainly composed of a mold plate 1, a worm strip 2, a baffle plate 3, a bump 4, a slide rail 5, a hanger 15 and a demoulding thimble assembly. Wherein, the mold plate 1 is a rectangular metal plate, and two snails 2 are respectively arranged on the two short sides of the mold plate 1, and the thread surfaces of the two snails 2 face away from each other, and the two snails 2 respectively pass through a baffle plate 3 is fixed with the side of mold plate 1. The upper surface of the mold plate 1 between two baffles 3 is densely covered with bumps 4, and these bumps 4 are arranged in an m*n rectangular array. There are gaps between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com