A vertical mortar mixer

A mixer and mortar technology, which is used in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems such as the proportion of mortar components is far away from expectations, the materials are not easily turned over, and the mixing is uneven, so as to improve reliability and use. Life, improve mixing efficiency, improve the effect of mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

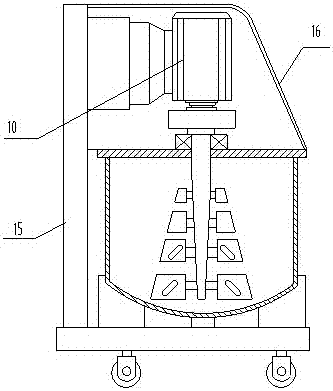

[0016] As shown in the figure, a mortar mixer includes a mixing box 3, and the bottom of the mixing box is designed as an arc surface, so as to facilitate cleaning.

[0017] The upper end of the mixing box 3 is provided with an opening, and the lower part of the mixing box 3 is provided with a discharge port 13 and a sewage outlet 14.

[0018] A support 12 is provided on the opening of the stirring box 3, and a drive device is provided on the support 12, and the drive device includes a motor 10 and a pinion 11 arranged on the output shaft of the motor.

[0019] The pinion 11 is meshed with two large gears 9 respectively, and the two large gears 9 are respectively arranged on two stirring shafts 6, and the stirring shaft 6 is supported on the support 12 through the pressure bearing 7, and the two large gears 9 are respectively arranged on the two stirring shafts 6. The stirring shafts are vertically arranged in parallel, and each stirring shaft is provided with 2-4 rows of stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com