Medium and deep hole blasting method

A technology of deep hole blasting and blast hole, which is applied in blasting and other directions, can solve problems such as inability to eliminate potential safety hazards, low operating efficiency, and high labor intensity of workers, and achieve the goal of reducing manual operation risks, eliminating potential safety hazards, and improving operating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

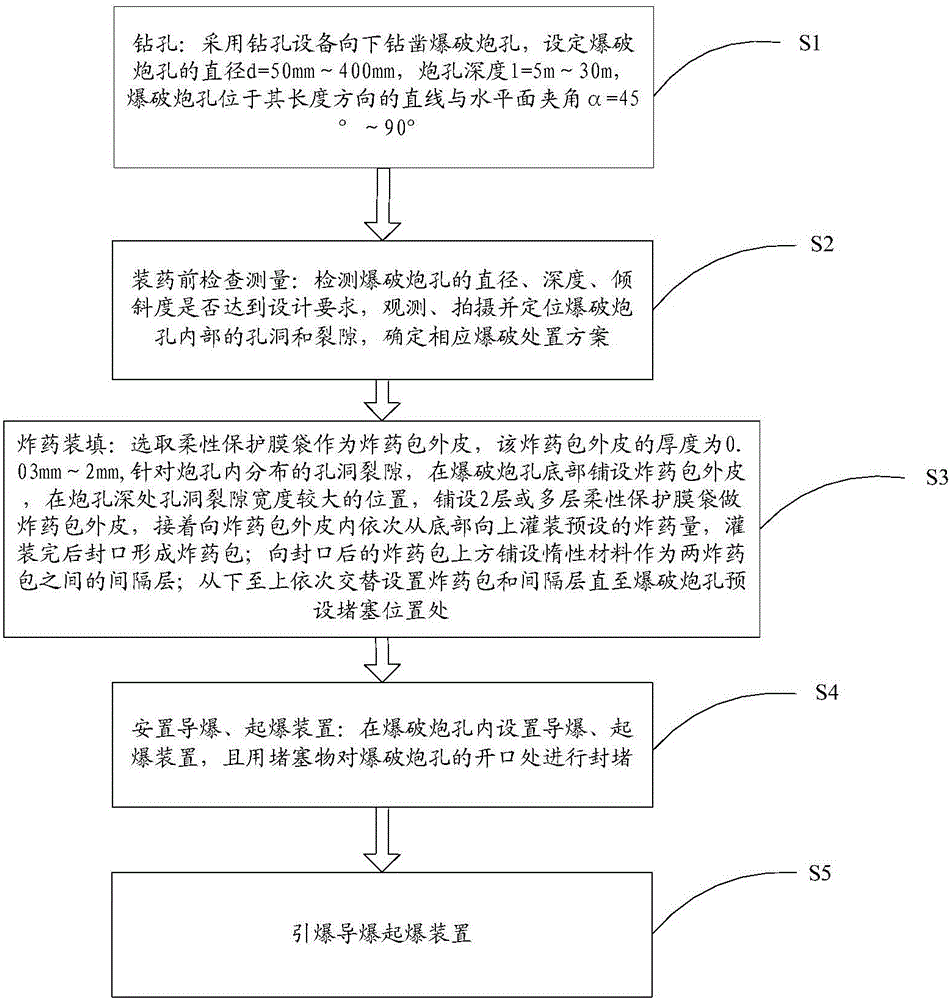

[0042] A medium-deep hole blasting method, such as figure 1 shown, including the following steps:

[0043] S1. Drilling: Use drilling equipment to drill down the blasting hole, set the diameter of the blasting hole d = 50mm ~ 400mm, the depth of the blasting hole l = 5m ~ 30m, and the blasting hole is located on the straight line and the horizontal plane in the direction of its length Angle α=45°~90°;

[0044] S2. Inspection and measurement before charging: detect whether the diameter, depth, and inclination of the blasting hole meet the design requirements, observe, photograph and locate the holes and cracks inside the blasting hole, and determine the corresponding blasting disposal plan;

[0045] S3. Explosive filling: Aiming at the holes and fissures distributed in the blast hole, lay an explosive package skin at the bottom of the blast hole, and fill the explosive package skin with the preset amount of explosives from the bottom to the top, and seal the explosive package ...

Embodiment 2

[0057] The difference between this embodiment and Embodiment 1 is that the diameter of the blasting hole is 50mm, the angle α between the straight line and the horizontal plane of the blasting hole in its length direction is 45°, the depth of the blasting hole is 5m, and the blasting hole is 5m deep. The film thickness of the sheath was 0.03 mm.

Embodiment 3

[0059] The difference between this embodiment and Embodiment 1 is that the diameter of the blasting hole is 400mm, the angle α between the straight line and the horizontal plane of the blasting hole in its length direction is 60°, and the depth of the blasting hole is 20m. The film thickness of the sheath was 2 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com