Staged vacuum preloading soft soil ground reinforcing technology

A technology of vacuum preloading method and soft soil foundation, which is used in the drainage treatment of soft soil foundation and silt. The staged vacuum preloading method can solve the blockage of drainage board, affect the degree of vacuum and reduce soil reinforcement. effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

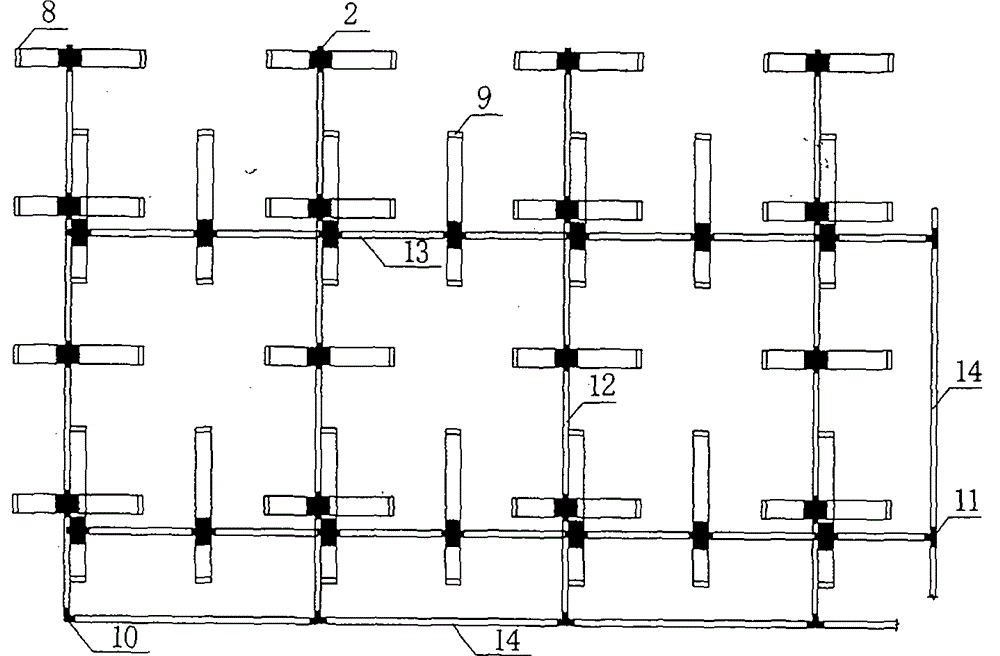

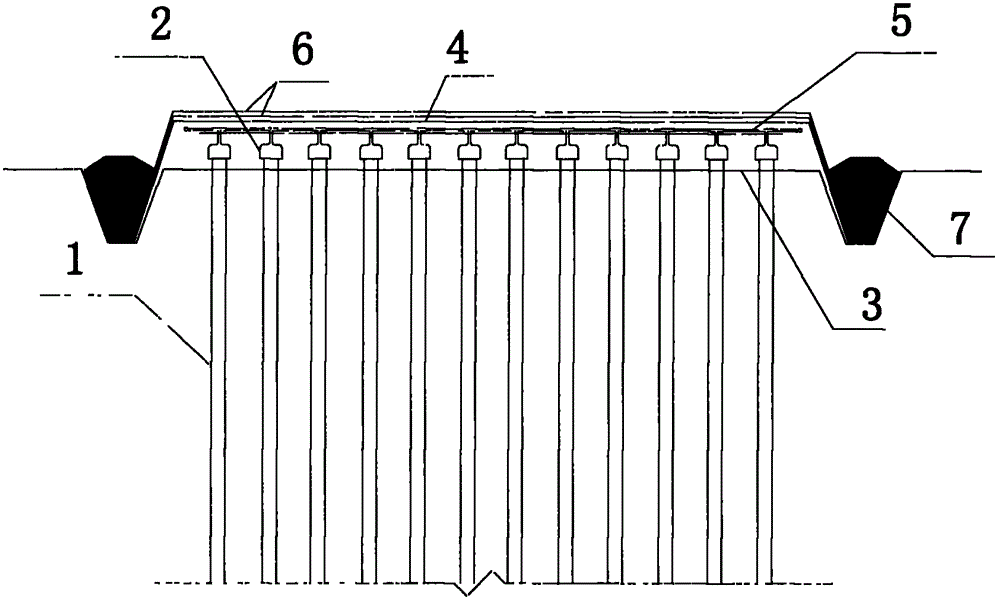

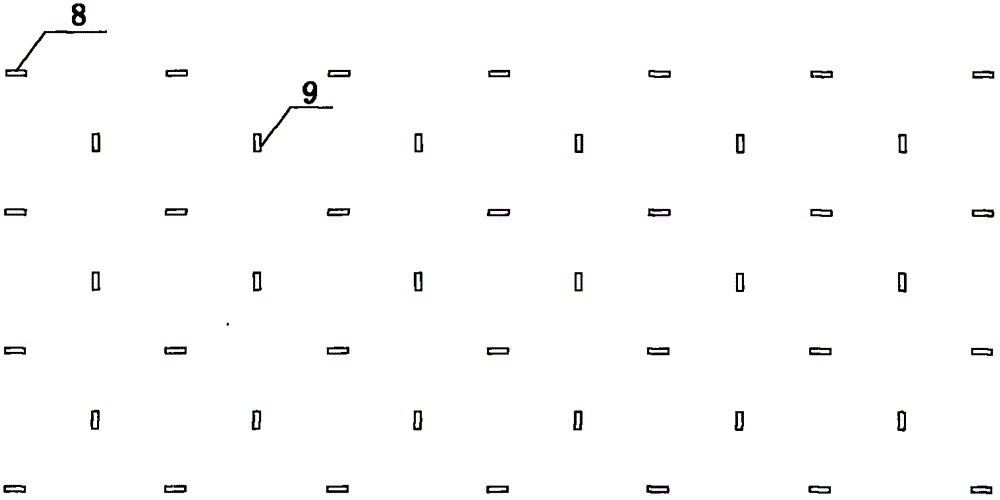

[0013] During specific implementation, a layer of woven cloth is laid on the soft ground that needs to be treated, the vertical drainage boards of the pretreatment vacuum system and the reprocessing vacuum system are positioned, and then the vertical drainage boards are installed. According to engineering experience, the spacing between drainage boards is 0.8-1.2m. At the same time, considering that the radius of the reverse filter layer of the drainage board is about 0.5m, the distance between the drainage boards is set to 0.8m. Connect the vertical drainage board of the pretreatment vacuum system with its horizontal drainage branch pipe, and connect the vertical drainage board of the retreatment vacuum system with its horizontal drainage branch pipe, and connect the horizontal drainage branch pipes of the two vacuum systems with their horizontal drainage main pipes respectively. To connect, lay a layer of geotextile, lay a layer of sealing film, respectively connect the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com