Screw supplying device

A screw machine and chassis technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of not being able to automatically screen out defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

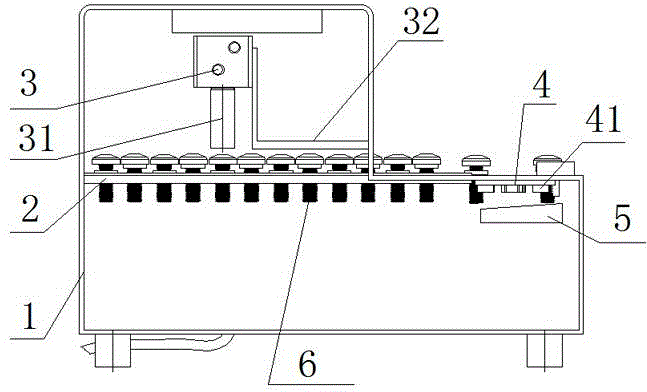

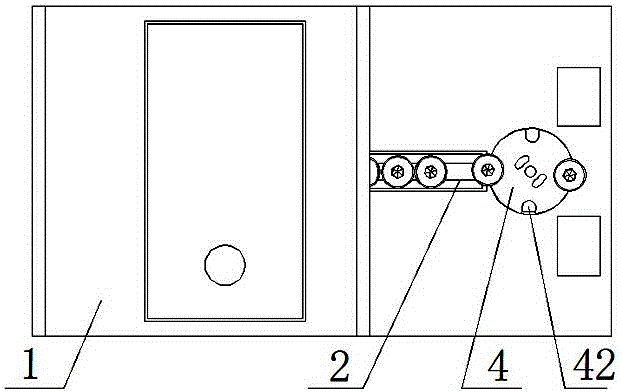

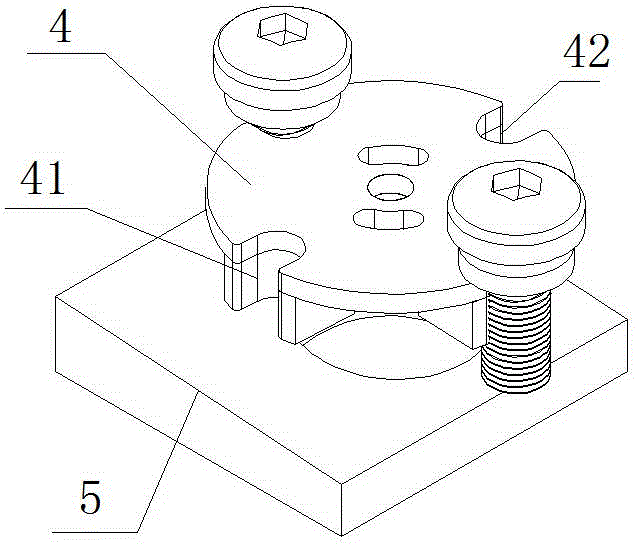

[0014] In this example, if Figure 1 to Figure 5 As shown, a screw machine of the present invention includes a chassis 1, a transmission guide rail 2 arranged transversely in the middle of the chassis 1, a screw 6 transported on the transmission guide rail 2, and a height-limiting frame 32 arranged above the transmission guide rail 2 , and the flattening cylinder 3 arranged at the center of the top inner side of the cabinet 1, and the pressing pin 31 arranged under the flattening cylinder 3, and the turntable 4 arranged at the right end of the transmission guide rail 2, and the limit position arranged at the edge of the turntable 4 Hole 42, and the protective block 41 that is arranged on the circumference of the turntable 4, and the limiting hole 42 that is arranged on the protective block 41, and the riser block 5 that is arranged under the turntable 4; the limiting hole 42 is provided with two Above, the shape of each of the limiting holes 42 is set in a semicircle, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com