Multi-heating-surface thick film heating body and printing device and technology thereof

A thick film heating and hot surface technology, applied in printing, heating element shape, printing device, etc., can solve problems such as small application range, easily damaged printed circuit waste, circuit resistance parameter changes, etc., achieve significant technical effects, overcome product Unstable, strong stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

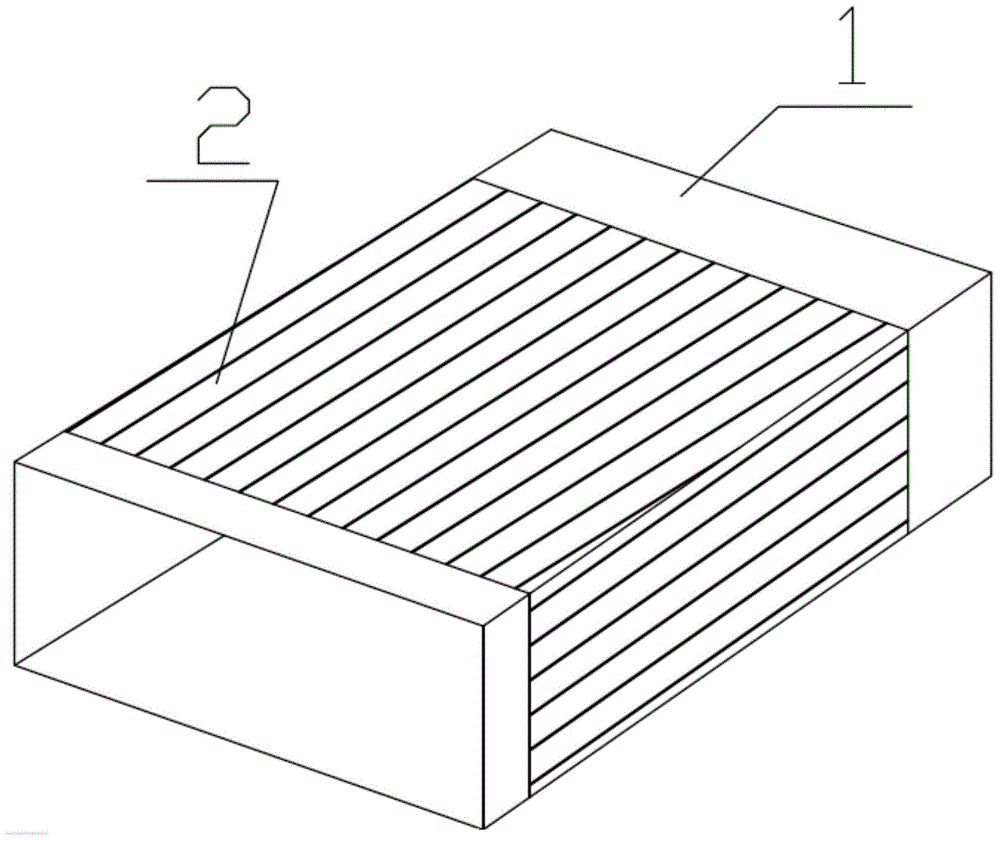

[0023] The present invention provides a multi-heating surface thick-film heating body, which comprises a polygonal tube body with three sides or more in section, and a heating circuit is printed on at least one side wall of the tube body. Preferably comprising a tubular body with a rectangular cross-section, such as figure 1 As shown, a heating circuit is printed on at least one side wall of the tube body. And the tube body is a polygon with at least one set of parallel sides.

[0024] Heating circuits are printed on the two side walls of the tube body. Or two or more side walls of the tube body are printed with heating circuits. It can also be set according to actual needs, for example, heating circuits are printed on two adjacent side walls of the tube body; heating circuits are printed on four side walls of the tube body.

[0025] Another object of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com