Plug-in outer-lead photovoltaic module junction box and solar photovoltaic module string

A photovoltaic module and junction box technology, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of contact resistance power loss, line power loss, long lead length, etc., to reduce power loss, improve power generation efficiency, reduce The effect of connecting points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

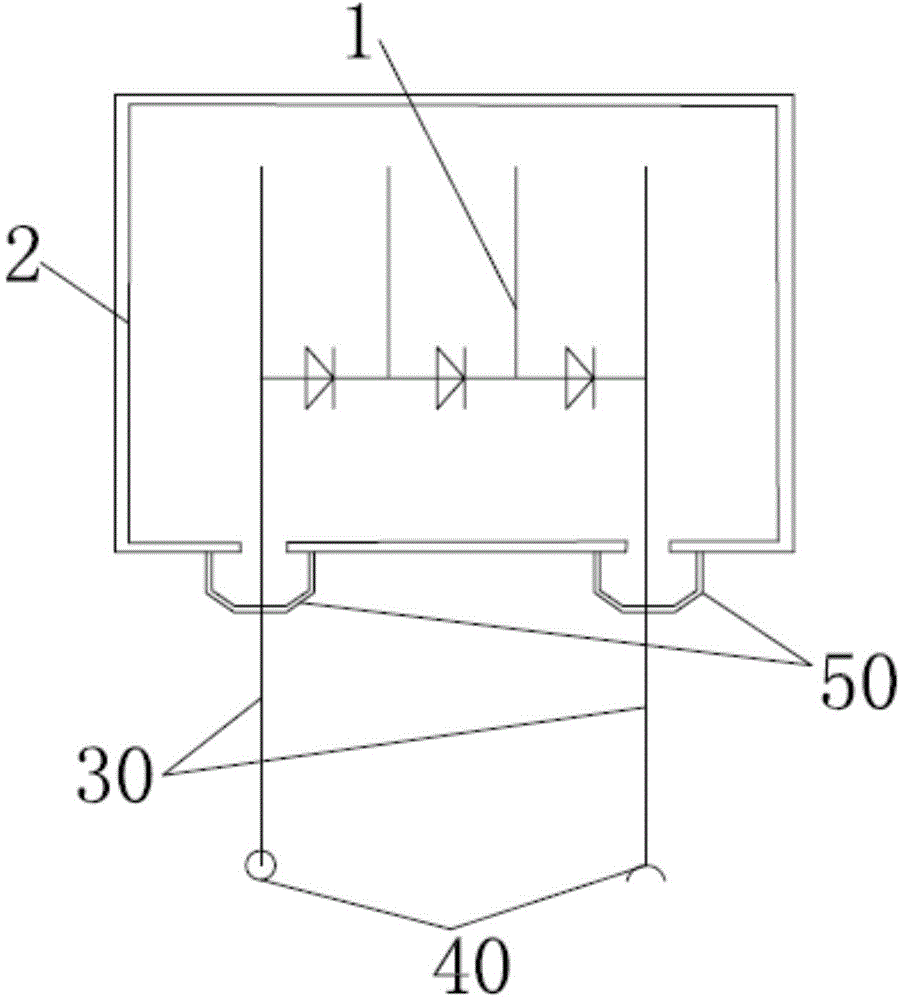

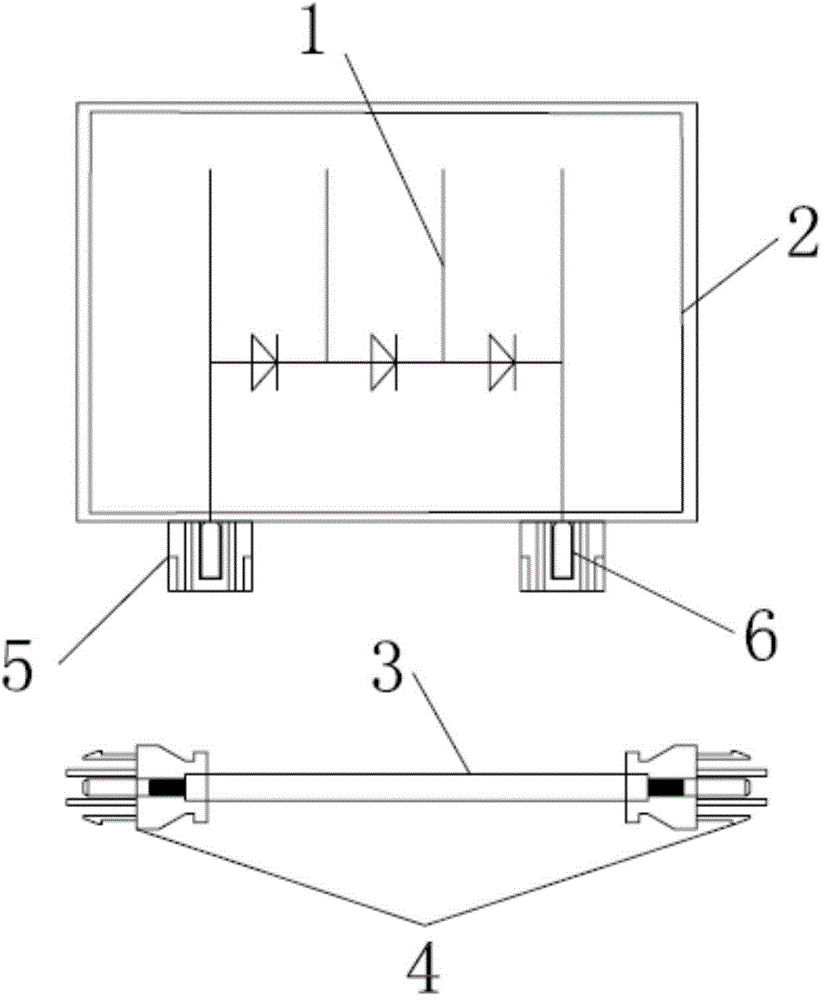

[0030] image 3 It is a schematic diagram of the structure of the plug-in type outer lead photovoltaic module junction box of the present invention.

[0031] Such as image 3 As shown, this embodiment provides a plug-in type outer lead photovoltaic module junction box, which includes a junction box body 2 with a built-in wiring circuit 1 and a connecting wire 3 for conducting and connecting different junction boxes. A plug 4 is provided. The junction box body 2 is provided with a negative socket 5 connected to the negative electrode of the wiring line 1 and a positive socket 6 connected to the positive electrode of the wiring line 1. The connecting wire 3 is detachably plugged into the negative electrode through the plug 4 Socket 5 or positive socket 6. The plug 4 may also be a 90-degree turning plug.

[0032] Exemplary, such as image 3 As shown, one of the plugs 4 at both ends of the connecting wire 3 is a male plug and the other is a female plug. The length of the connecting wi...

Embodiment 2

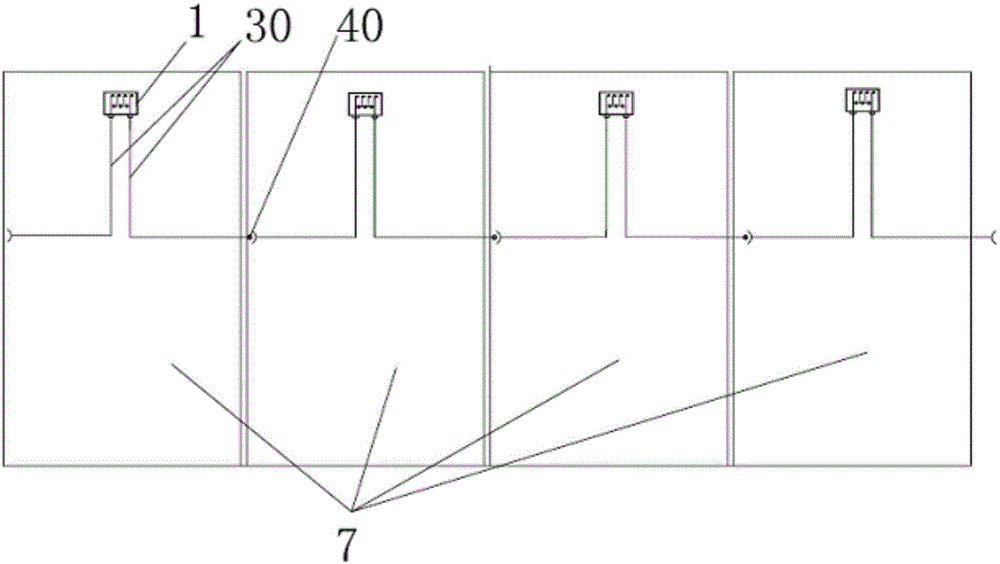

[0036] Figure 4 , Figure 5 These are schematic structural diagrams of two specific embodiments of the solar photovoltaic module string of the present invention, and the principles of the two are the same.

[0037] Such as Figure 4 As shown, this embodiment proposes a solar photovoltaic module string, including several photovoltaic modules 7, each photovoltaic module 7 is provided with a junction box, the junction box adopts the plug-in outer lead photovoltaic module described in the first embodiment The junction box and the photovoltaic modules 7 are connected in series, and the negative socket of the junction box of one photovoltaic module is connected to the positive socket of the junction box of the other photovoltaic module in turn, and the negative socket and the positive socket are connected through the connection Wire to connect, or as Figure 5 Shown.

[0038] Exemplary, such as Figure 4 As shown, the number of photovoltaic modules 7 is 22. All the photovoltaic module...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com