Endurance test device for temperature valve

A technology of durability test and temperature valve, which is applied in the direction of measuring devices, strength characteristics, instruments, etc., can solve the problems of slow heating and cooling speed of high and low temperature impact box, inconvenient observation of temperature valve action, high operating cost of high and low temperature impact box, etc., to achieve The effect of low cost, simple structure and convenient durability test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

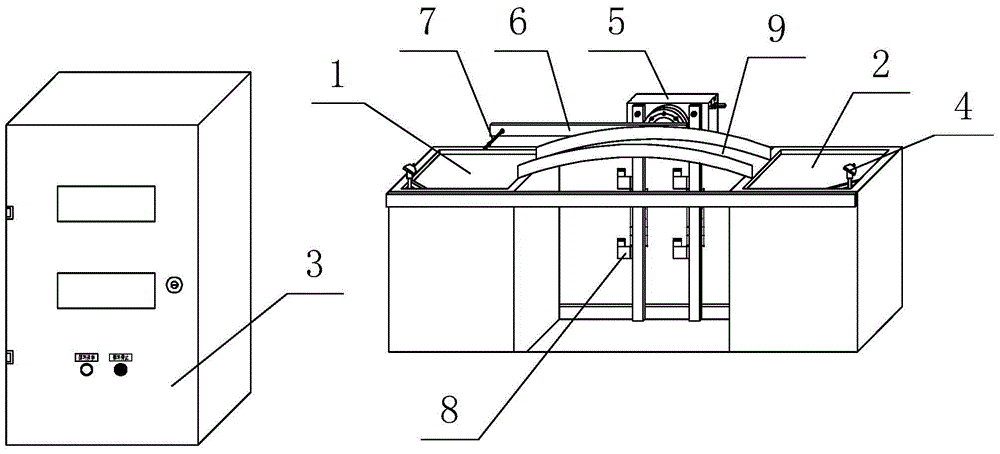

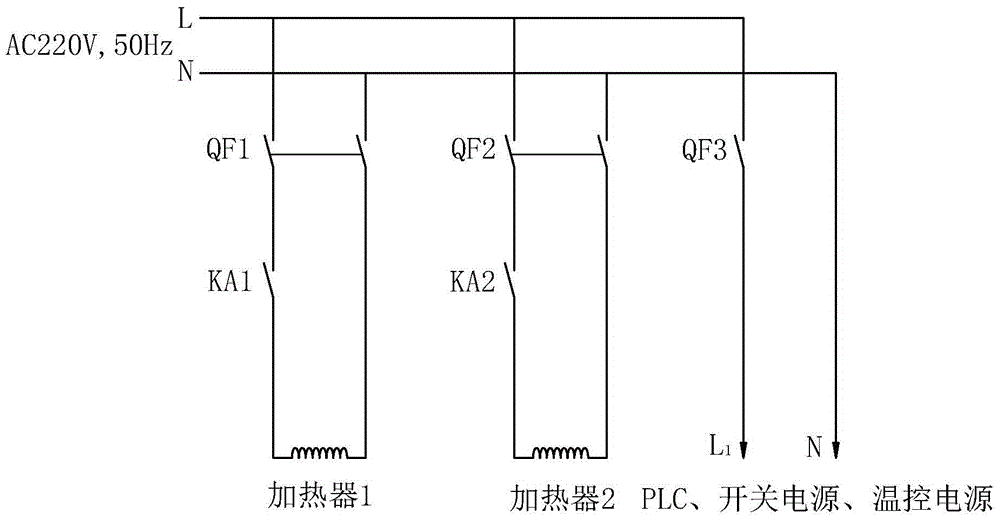

[0012] Embodiment 1: as figure 1 and figure 2 As shown, the present invention includes a high-temperature pool 1, a low-temperature pool 2 and an electrical control cabinet 3, a thermocouple 4 is respectively arranged outside the high-temperature pool 1 and the low-temperature pool 2, and a thermocouple 4 is arranged between the high-temperature pool 1 and the low-temperature pool 2. Rotary cylinder 5, said rotary cylinder 5 is located in the middle of the connection line between high temperature pool 1 and low temperature pool 2, said rotary cylinder 5 is provided with a rocker arm 6, one end of rocker arm 6 is connected with rotary cylinder 5, and the other end is provided with There is a fixed rod 7 for fixing the temperature valve. The fixed rod 7 is located on the side of the rocker arm 6 close to the high temperature pool 1 and the low temperature pool 2. The rotary cylinder 5 is provided with a solenoid valve 8 for controlling its work. The electric The control cabine...

Embodiment 2

[0013] Embodiment 2: Same as the above-mentioned embodiment 1, wherein an arched protective liquid tank 9 is connected between the above-mentioned high temperature pool 1 and low temperature pool 2, and the highest point of the protective liquid tank 9 is located at the high temperature pool 1 and the low temperature pool 2 The center plane of the connecting line.

[0014] During the use of the present invention, the temperature valve to be tested is first fixed on the fixed rod 7, and then the high-temperature pool 1 and the low-temperature pool 2 are electrically heated through the electric control cabinet 3 to make them reach the temperature required for the test, and then the temperature valve Put it into the high-temperature pool 1, and after a certain period of time, control the rocker arm 6 by rotating the cylinder 5, move the temperature valve to the low-temperature pool 2, and conduct a temperature change test. The arched protective liquid tank 9 is set in the middle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com