Biomass burner

A burner and biomass technology, applied in combustion methods, combustion equipment, solid fuel combustion, etc., can solve the problems of easy blockage of biomass particles, low motor power, and reduction of biomass particles, so as to solve the problem of equipment not operating normally , High combustion efficiency and full combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

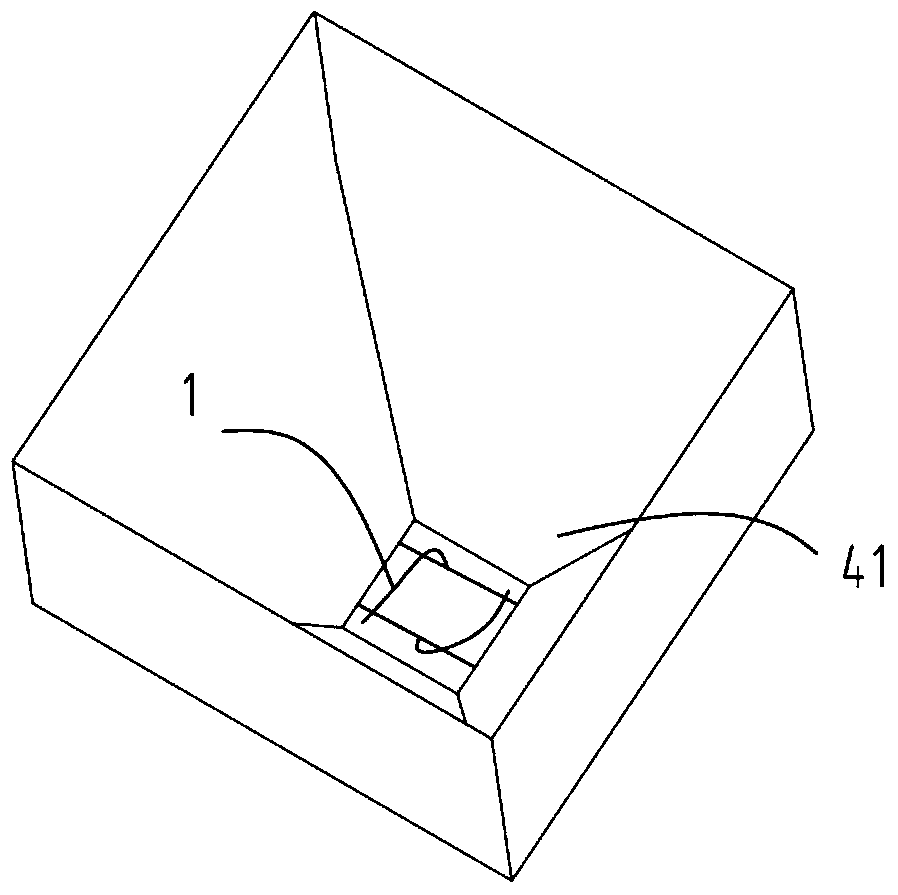

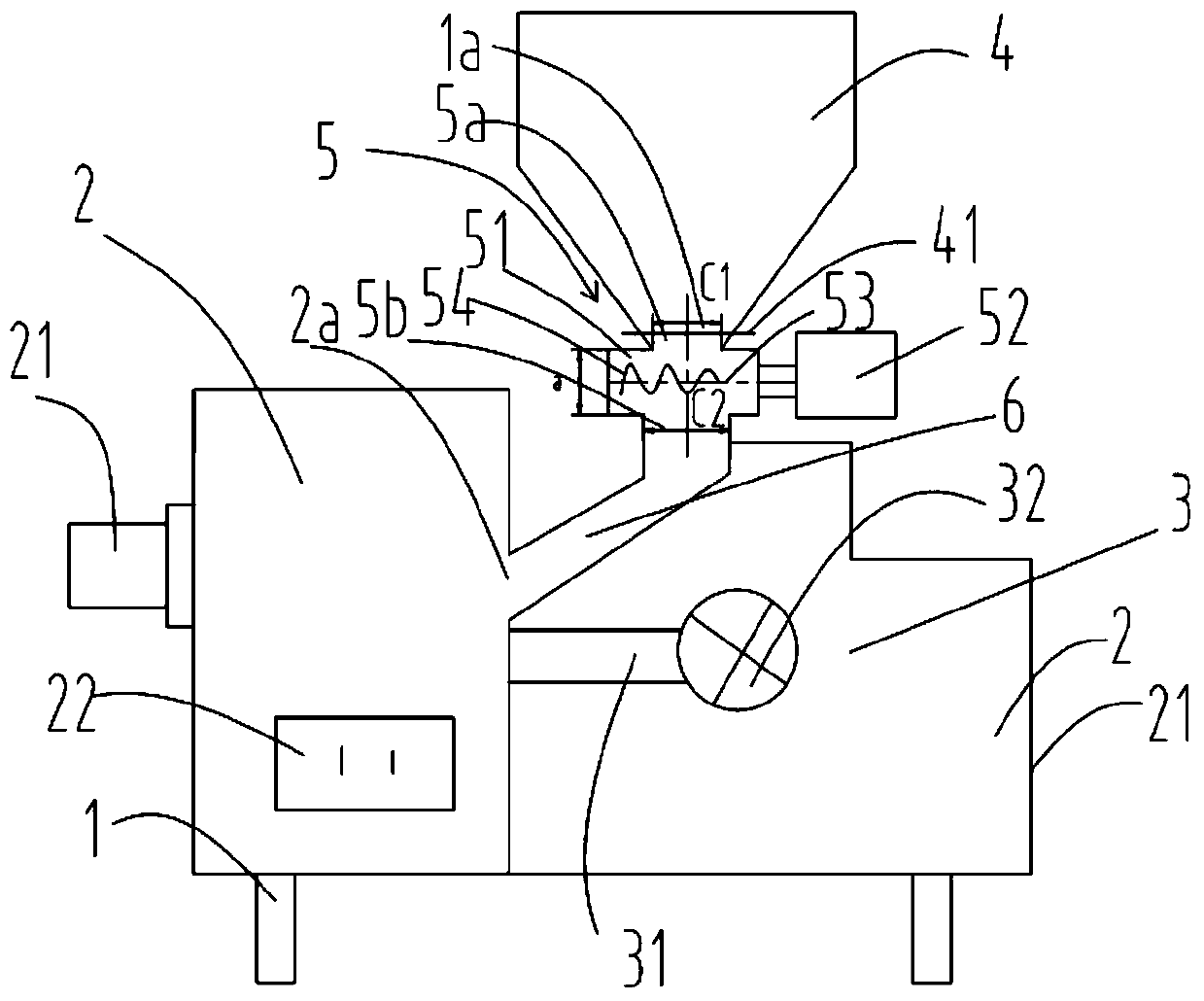

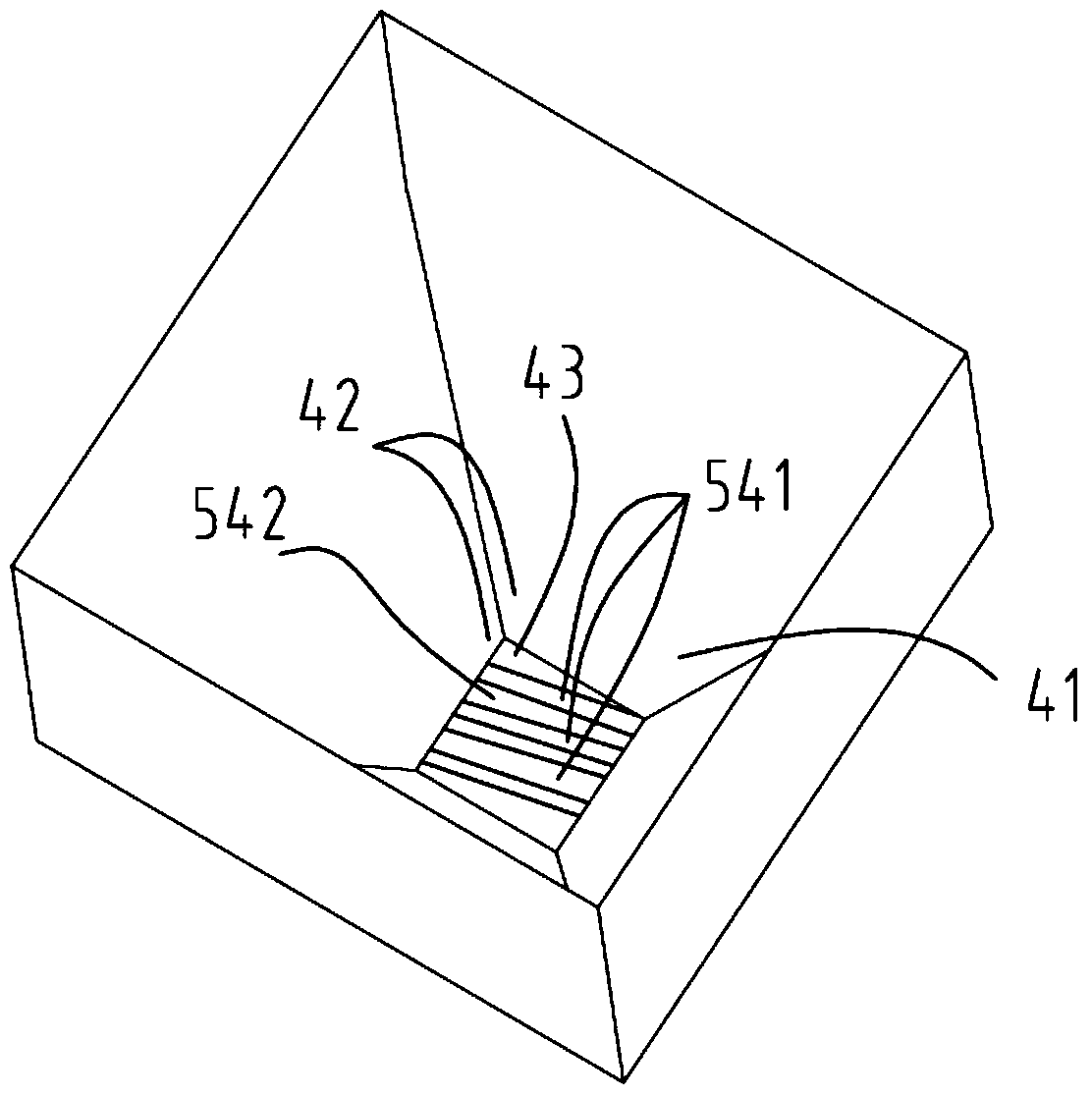

[0036] figure 2 It is a schematic structural diagram of Embodiment 1 of a biomass burner of the present invention; image 3 It is a top view structure schematic diagram of the feeding part of a biomass burner of the present invention;

[0037] Such as figure 2 and image 3 As shown, a biomass burner includes a frame 1, a combustion chamber 2 arranged on the frame, an air chamber 3 located on one side of the combustion chamber, and a storage bin 4 located above the air chamber 3. The air chamber 3 and The combustion chamber 2 communicates with the air-introduction channel 31, and one end of the air-induction channel 31 is provided with a blower fan 32, and the other end leads into the combustion chamber 2; the combustion chamber 2 communicates with the storage bin 4, and the biomass particles The bin 4 enters the combustion chamber 2 for combustion, and the combustion chamber 2 is also provided with a flame nozzle 21 and an ash outlet 22, and also includes a feeding module...

Embodiment 2

[0045] Figure 7 It is a structural schematic diagram of Embodiment 2 of a biomass burner of the present invention. Such as Figure 7 As shown, the series feeding module 7 shown in this embodiment includes two sets of feeding modules 5 connected in series, and the biomass particle fuel enters the feeding module 5 through the feed bin and then enters the combustion chamber 2 . In this example, the two feeding modules 5 of the feeding module 10 are respectively driven by two shut-off fans 72, and the shut-off fans 72 are the same as the shut-off fans 52 in the embodiment. Of course, the two sets of feeding modules 5 can also be driven by one quantitative feeder. In this embodiment, except for the differences described above, other structures, positional relationships and connection relationships are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com