Conveyor Belts Using Magnetic Couplings

A technology of couplers and conveyor belts, applied in the field of conveyor belts, can solve the problems of no solution proposed, large-scale conveyor belt beyond the containment range, excessive cost and time, etc., and achieve the goal of reducing the cost and time required for transfer and installation, as well as various problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Advantages and features and prior methods of the present invention will become apparent with reference to the accompanying drawings and embodiments to be described in detail.

[0030] However, the present invention is not limited by the following embodiments and can be realized in various forms. The purpose of this embodiment is to better illustrate the present invention and provide help for those skilled in the art of the present invention to understand, and the present invention Limited only by the claims. In this specification, the same reference numerals refer to the same elements.

[0031] Next, the bed Song Dynasty using the magnetic coupler of the present invention will be described in detail with reference to the accompanying drawings.

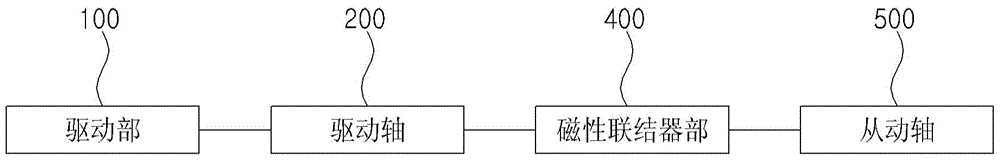

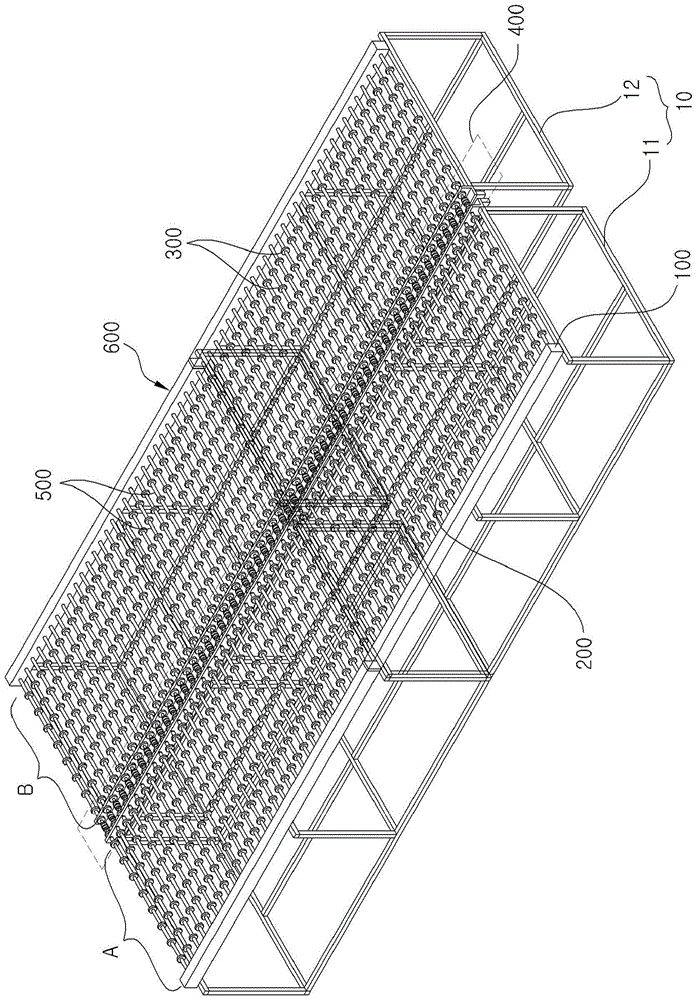

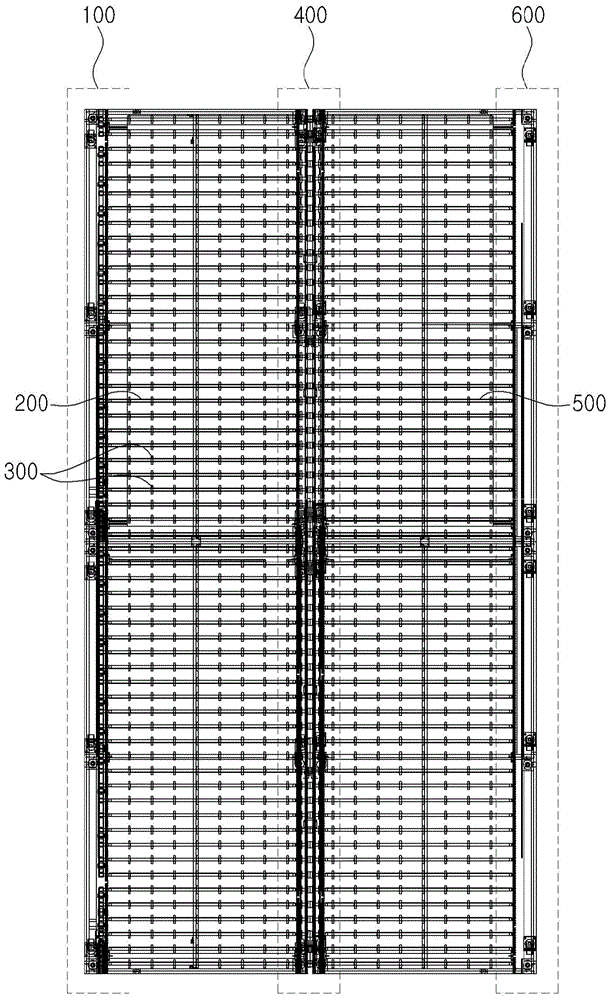

[0032] figure 1 is a schematic structural block diagram of a conveyor belt using a magnetic coupling in a preferred embodiment of the present invention, and Figure 2 to Figure 5 Each is a perspective view, a plan view, a fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com