Automatic jacking type storing and picking method and device thereof for long-pole materials

A storage device and material technology, which is applied to the storage and retrieval system of long-rod materials, can solve the problems of difficult material storage, large space occupation, inconvenient material acquisition, etc., so as to improve storage capacity, improve management level, and save working capital. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In order to solve the storage of long rod materials, due to the characteristics of small cross-section and large length, there are certain difficulties in the storage of materials. The present invention provides a jack-up automatic long rod material storage system, which is mainly used in long The storage of rod material realizes its automatic access.

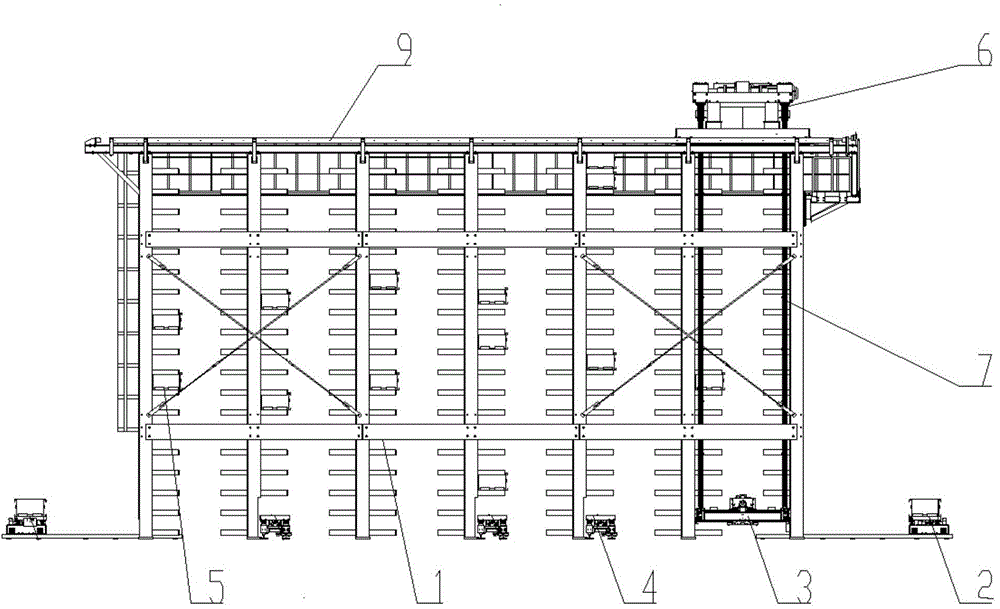

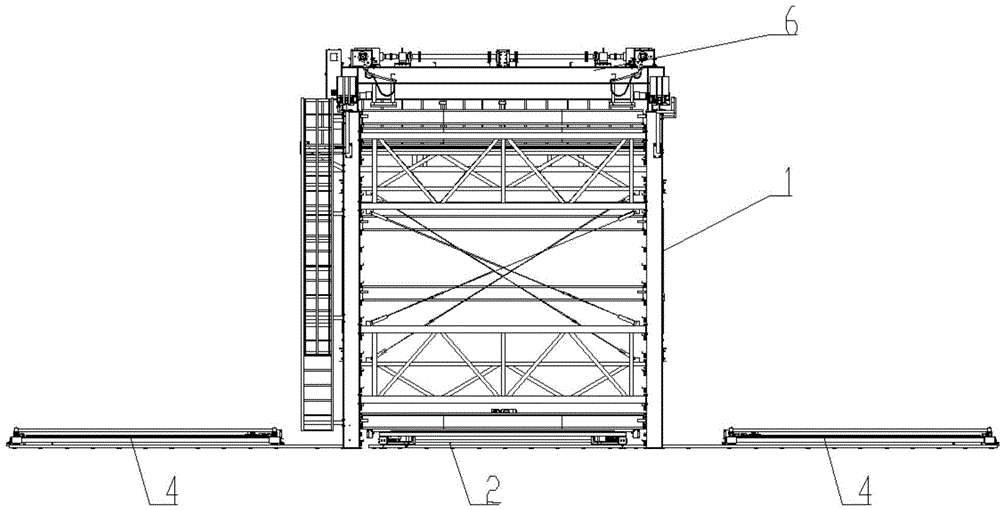

[0031] The invention provides a jack-up type automatic long rod material access device, such as Figure 1-3 As shown, it includes a shelf 1, a hopper 5, a crane 6 and an elevator car 3. The crane 6 is located on the sky rail 9 at the top of the jack-up automatic long-pole material access device, and drives the elevator car 3 to move up and down through the lifting system. , wherein the automatic access crane 6 and the lifting car 3 are the most active components of the whole system, and the storage of the hopper 5 is mainly completed by them through the control system.

[0032] Such as Figure 4-6 As shown, the lift ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com