Brake device supporting rail-compatible running of trapped rail car

A technology of braking device and rail truck, which is applied in the direction of braking, transportation and packaging, railway braking system, etc. where the braking element interacts with the track, to achieve the effect of avoiding collision, fast installation or disassembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. This embodiment is only used to explain the present invention and does not limit the protection scope of the present invention.

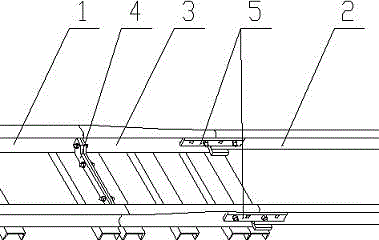

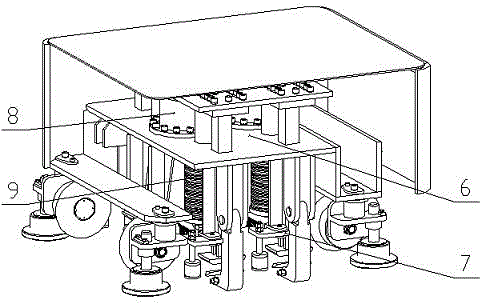

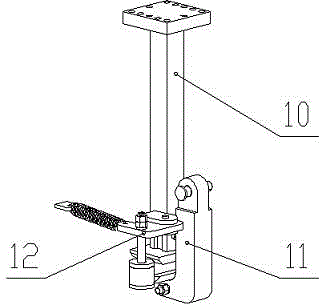

[0025] Example Figure 1-10 As shown, the present embodiment provides a braking device that supports the simultaneous operation of rail-cars, including a vehicle frame 6, an oil cylinder 8, and a disc spring 9, and also includes a number of lifting block hook swing mechanisms 7, preferably 4 , distributed symmetrically, the oil cylinder 8, the disc spring 9 and the lifting block hook swing mechanism 7 are arranged inside the vehicle frame 6, the disc spring 9 is arranged at the bottom of the oil cylinder 8, and the lifting block hook swing mechanism 7 includes A briquetting assembly 10, a lifting block assembly 11 and a hook pendulum 12. The briquettin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com