pneumatic tire

A technology for pneumatic tires and treads, used in tire parts, treads, transportation and packaging, and can solve problems affecting quality and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

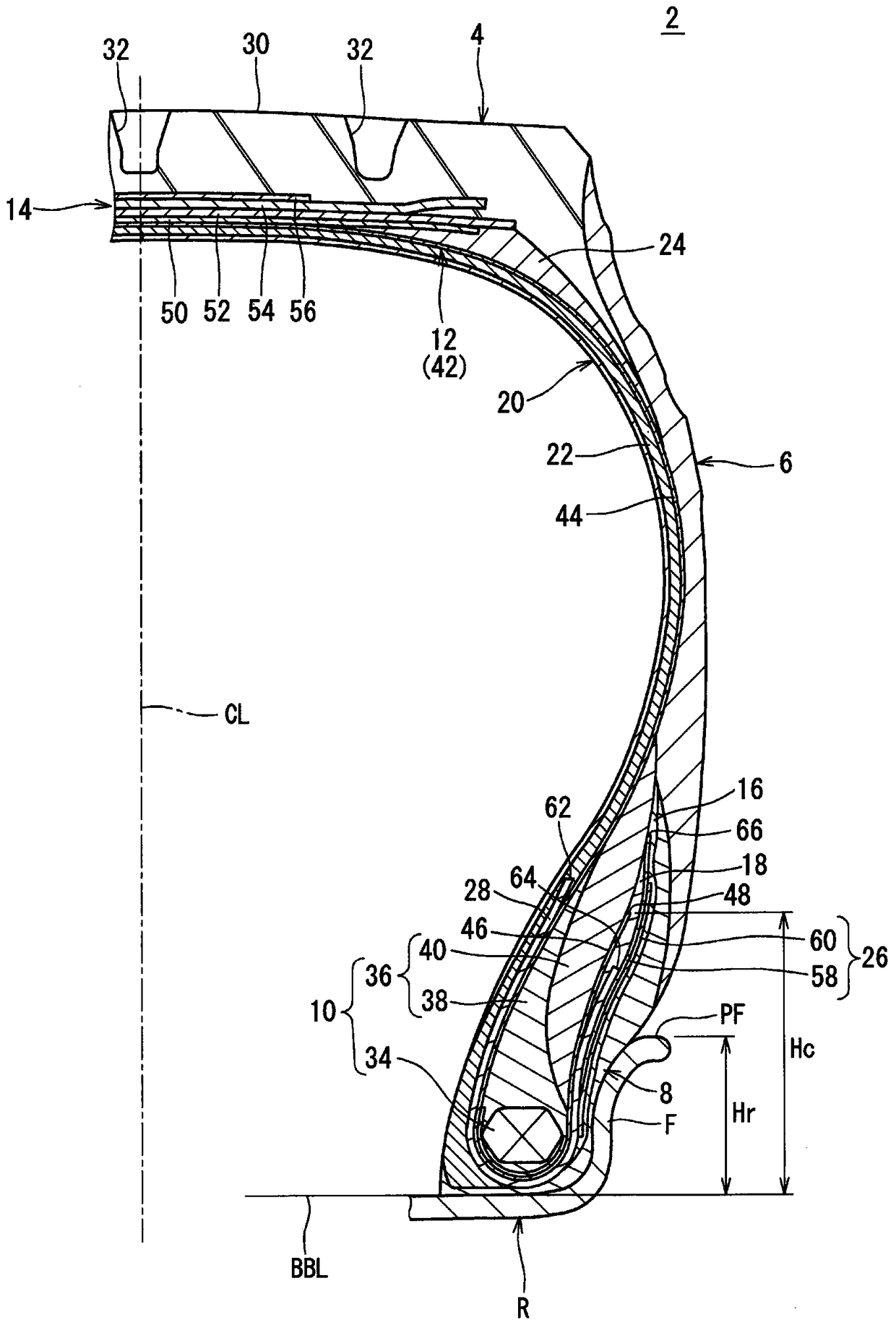

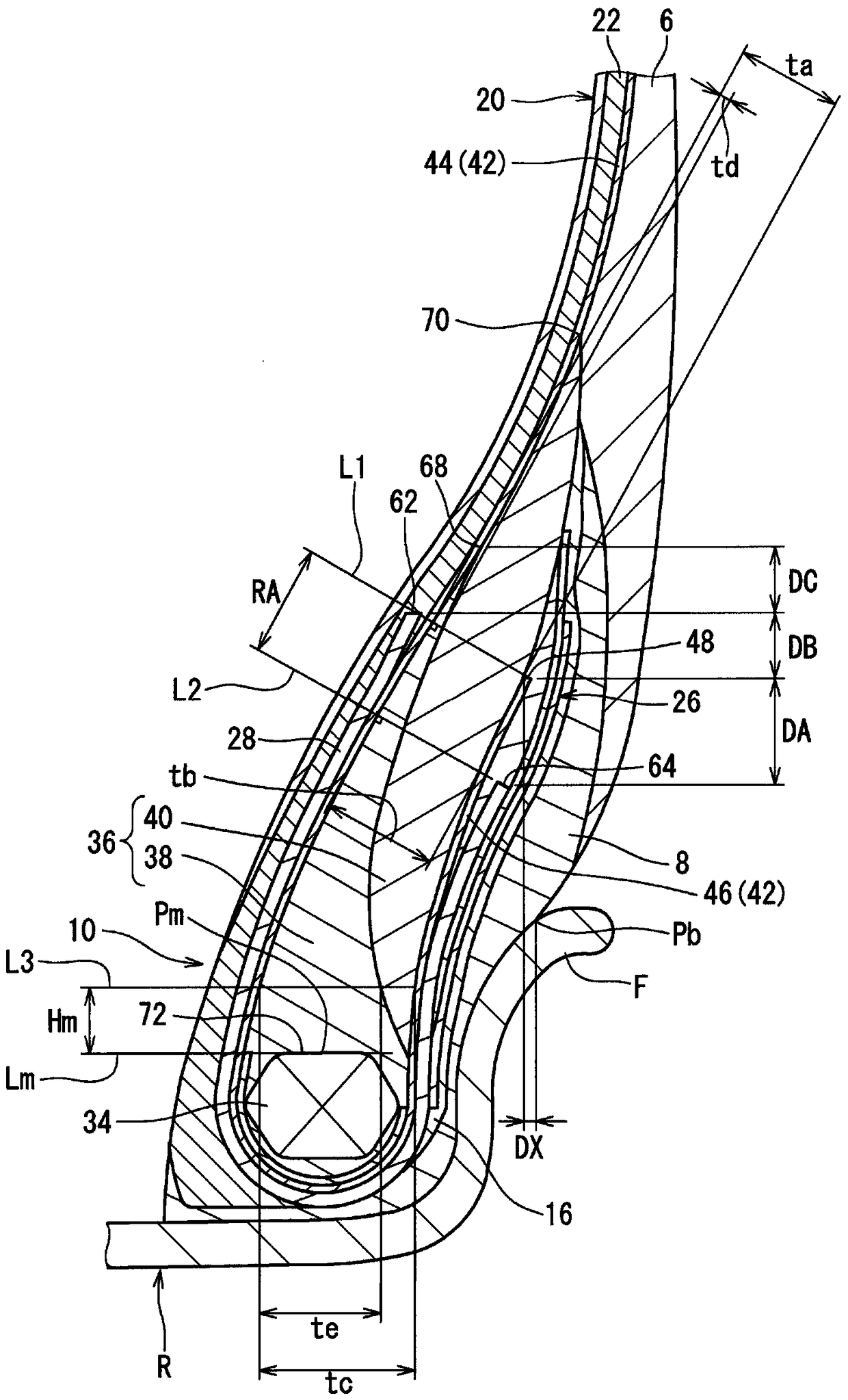

[0108] obtained with figure 1 A heavy-duty pneumatic tire according to Example 1 having the basic structure shown and the specifications shown in Table 1 below. The size of the tires is 12.00R20. The tire has a first filler. This situation is represented by "Y" in the first glue column of the table. A cord composed of nylon fibers was used for the cord contained in the first filler. The height in the radial direction from the bead base line to the outer end of the first filler was set at 95 mm. The height in the radial direction from the bead base line to the outer end of the hard portion was set to 90 mm. The radial direction height Hc from the bead base line to the end of the turnback portion was set to 75 mm. The size of the rim on which this tire was assembled was 8.8×20, and the height Hr of the flange of the rim was 45 mm.

Embodiment 2-5 and comparative example 2-3

[0112] Tires of Examples 2-5 and Comparative Examples 2-3 were obtained in the same manner as in Example 1 except that the height Hc was adjusted to set the ratio (Hc / Hr) as shown in Tables 1 and 2 below.

Embodiment 6 and comparative example 4-5

[0114] Tires of Example 6 and Comparative Examples 4-5 were obtained in the same manner as in Example 1 except that the distance DB was set as in Table 2 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com