Intermittent sugarcane sugar boiling and crystallization process multi-objective optimization method

A multi-objective optimization and intermittent technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve complex problems such as impact, and achieve the effect of improving the level of automation, wide distribution of population diversity, and good operation strategies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0035] As pointed out in the background technology, process variables interact with seeding crystal characteristics, and have complex effects on the average crystal size and crystal size variation coefficient. Therefore, the difficulty in multi-objective optimization of the intermittent sugarcane boiling and crystallization process is how to find process variables and seeding. Potential correlation between crystal characteristics and product quality.

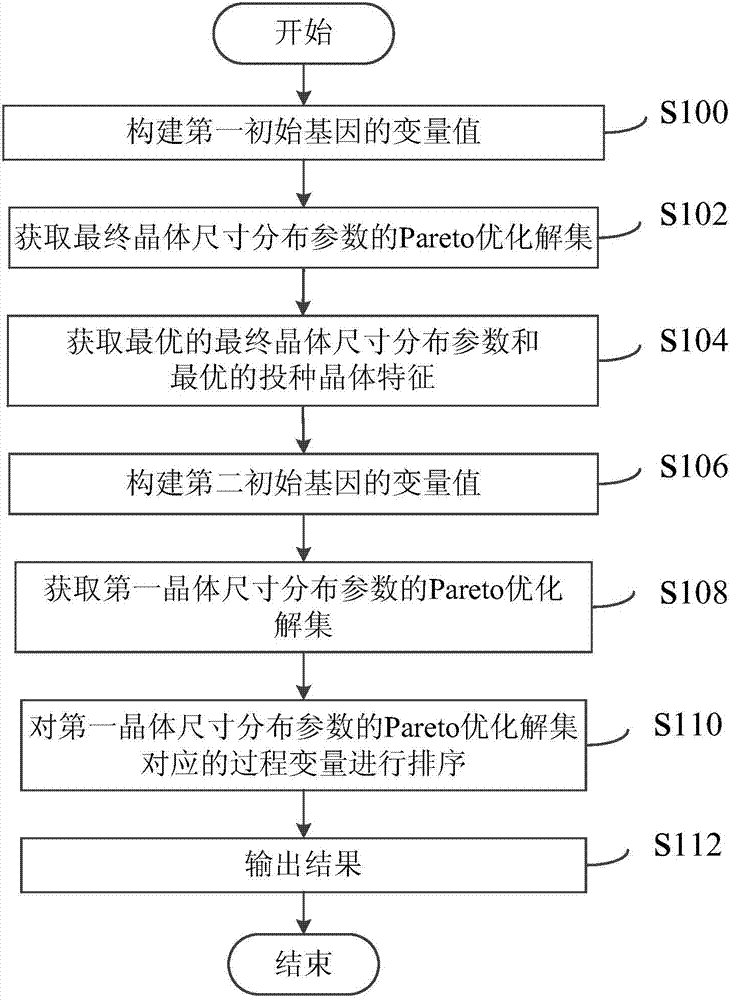

[0036] Such as figure 1 Shown, according to a kind of intermittent sugar cane boiled sugar crystallization process multi-objective optimization method according to the specific embodiment of the present invention, comprises the following steps:

[0037] Step S100: Obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com