Three-dimensional twisted and rotated inclined reinforced concrete frame structure formwork and its construction method

A reinforced concrete and frame structure technology, which is applied in the direction of formwork/template/work frame, formwork/formwork/work frame connector, building structure, etc., to achieve the effect of saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

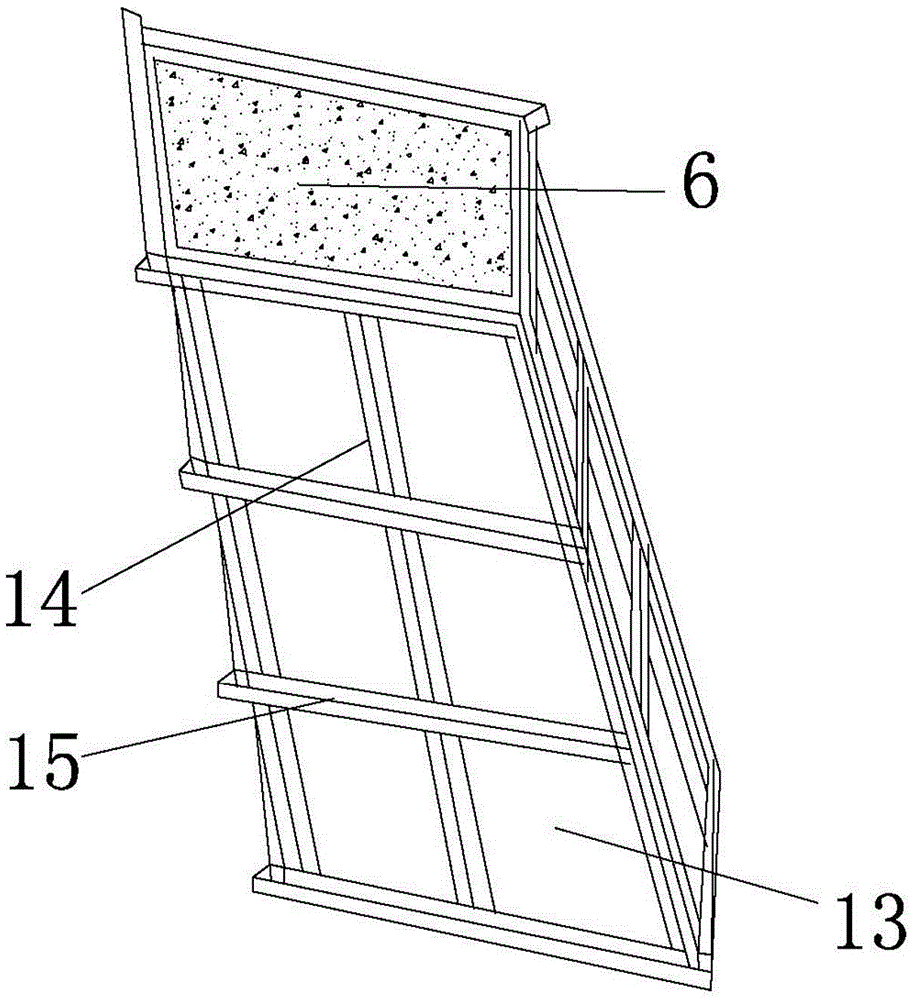

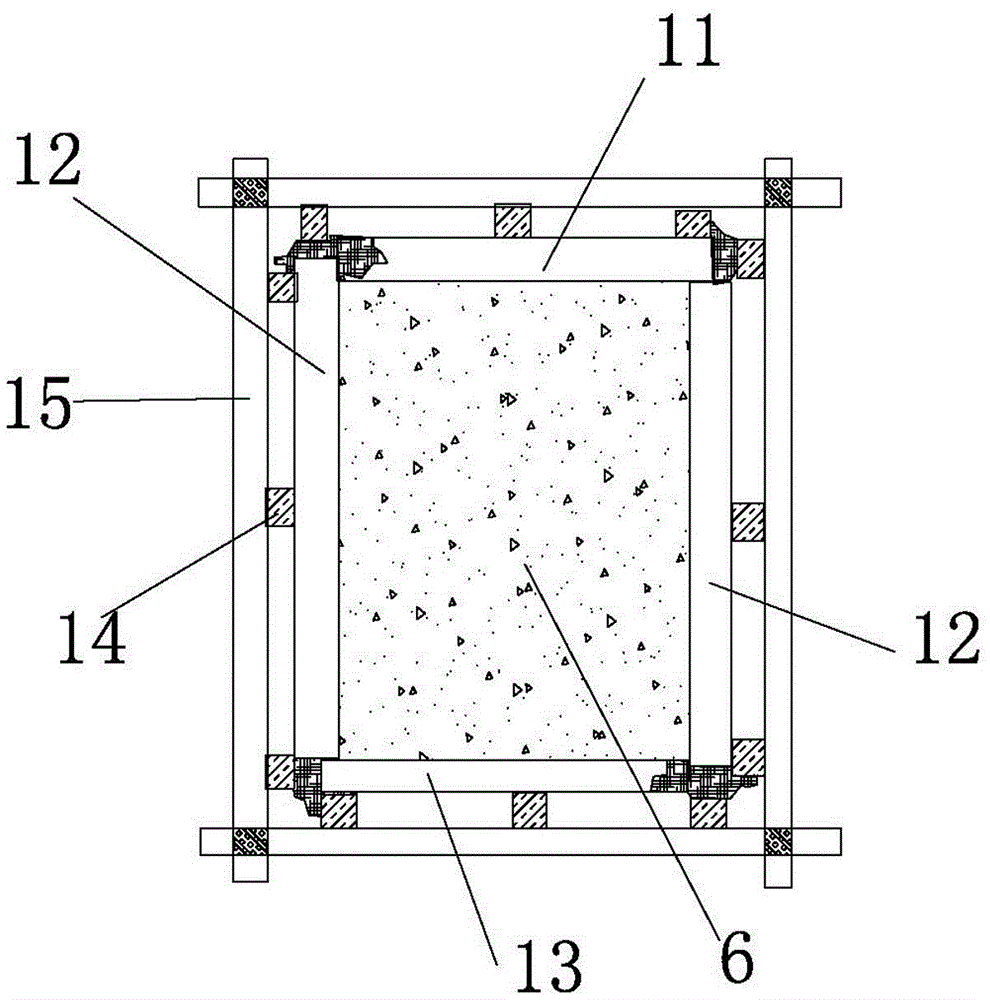

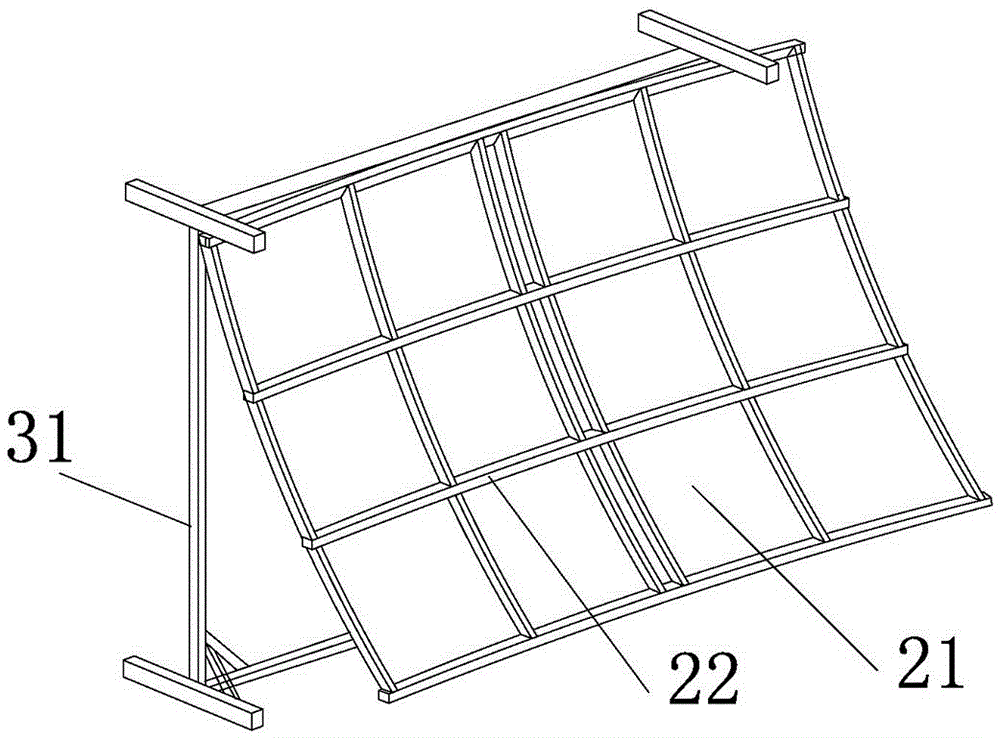

[0017] The design and processing of the skirt column formwork subverts the traditional column formwork and wall formwork design methods. The main measures taken are: first, according to the elevation and horizontal section projection size, the skirt column formwork inner tube mold and skirt board tire are produced in sections. Then use the four curved surfaces formed by the inner tire mold of the skirt column formwork to cover the multi-layer board on the inner tire mold skeleton of the skirt column formwork, and then bend the square steel back corrugated into an arc, and fix it on the multi-layer board with self-tapping dovetail screws board. The apron formwork uses the square steel tire frame, finds out the arc on the tire frame, and bends the square steel. The four square steels are welded to form a twisted surface, and the multi-layer board is fixed on the square steel frame with self-tapping dovetail screws. Form a twisted arc. The difference between the two is that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com