Farmland irrigation wire and hose winder

A technology of farmland irrigation and pipe reel, which is applied in the field of farmland irrigation reeling machine, can solve problems such as unfavorable handling, storage, unfavorable next use, and irregular collection, and achieves good popularization and application value, saves money, and quickly The effect of conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

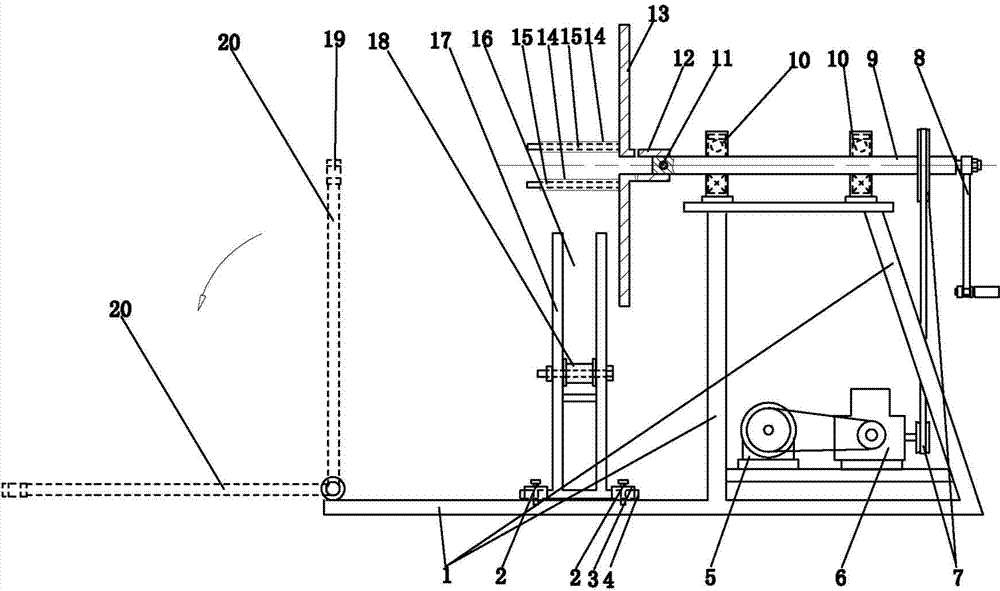

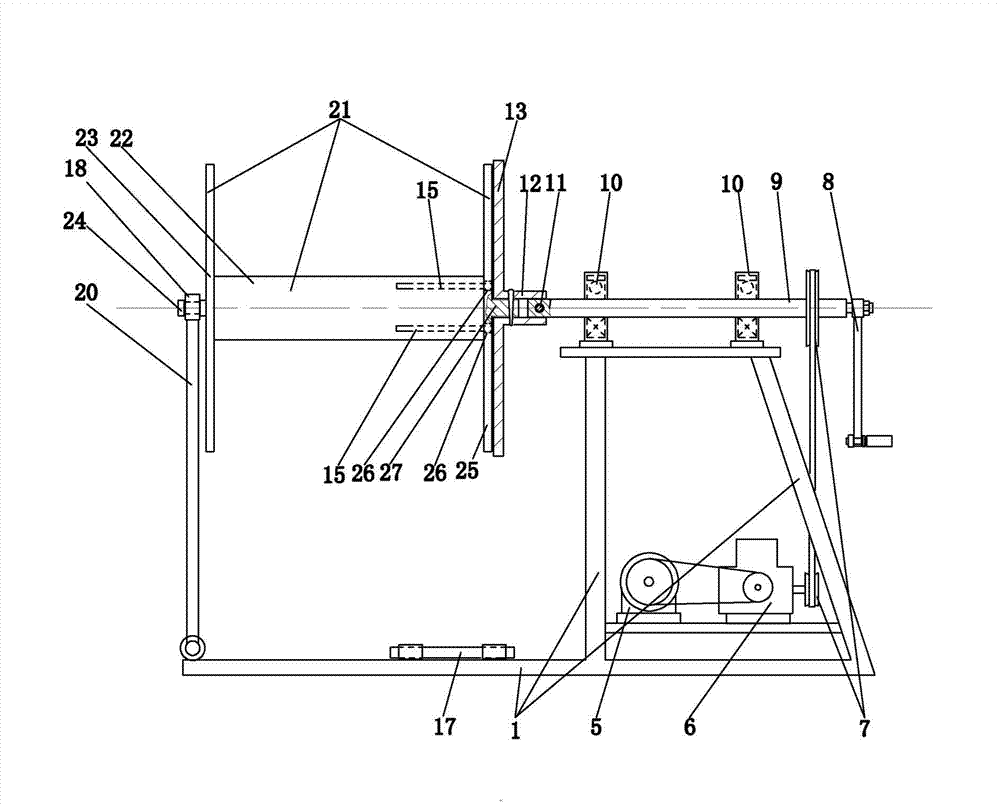

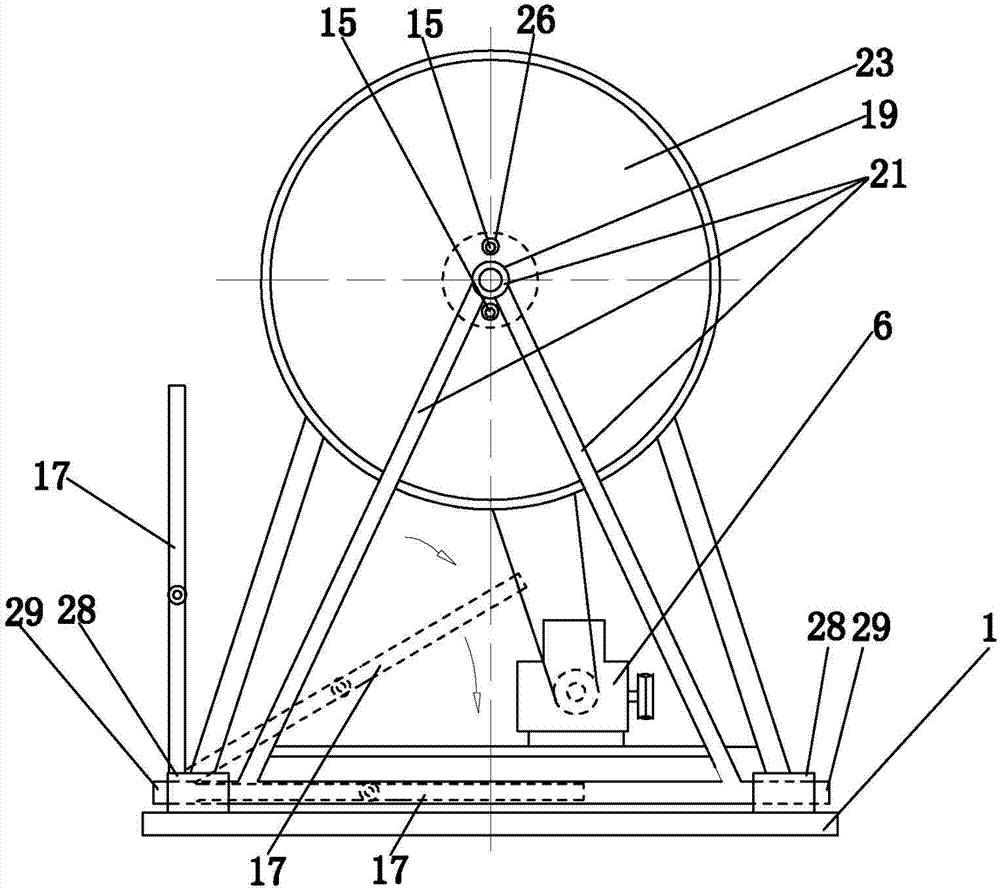

[0022] Such as figure 1 , figure 2 As shown, the present invention mainly includes a turntable 13, a rotating shaft 9, a base frame 1, and a power unit. The turntable 13 is set upright, and the rotating shaft 9 is horizontally arranged on the upper part of the base frame 1 through a pair of bearings 10. The right end surface of the turntable 13 is fixedly provided with a connecting sleeve. Tube 12, one end of the rotating shaft 9 penetrates the connecting sleeve 12, and is connected with the connecting sleeve 12 through the connecting pin 11, the rotating disk 13 and the rotating shaft 9 can also be connected by other means such as a coupling, the power device is a manual crank 8, and the rotating shaft The other end of 9 is connected with bolts between the hand crank 8; perhaps the power unit is a motor 5, and the rotating shaft 9 is connected with the output end of the motor 5 through the reduction transmission gear box 6, the belt drive 7.

[0023] When used as a winding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com