Worktable of plate shearing machine

A workbench and shearing machine technology, applied in shearing machine equipment, shearing devices, manufacturing tools, etc., can solve problems such as uneven edges, plate size deviation, and high requirements for workers' technical level and tacit understanding, to prevent Accidental movement, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

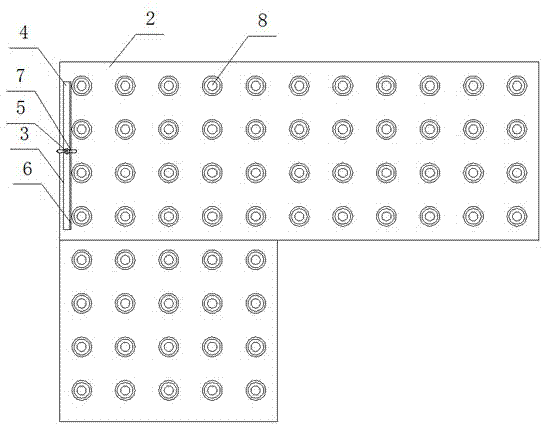

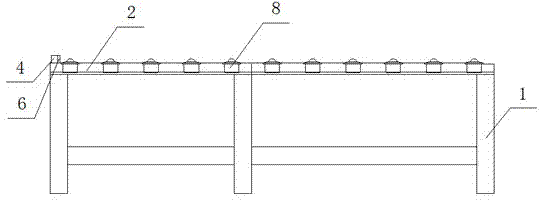

[0018] A kind of plate shearing machine workbench as shown in the figure, comprises support 1, sliding panel 2 and positioning caliper 3; 2 active connections. The clamping piece 4 is provided with a clamping bar 6 , and a screw thread is provided on the rotating pin shaft 5 , and the screw thread is connected with a wing nut 7 . The sliding panel 2 is divided into two pieces, which are spliced in an L-shape. Universal wheels 8 are evenly arranged on the sliding panel 2 . The clamping strip 6 is made of rubber.

[0019] During use, the rotation and displacement of the plate is realized by the universal wheel 8, and the positioning reference is determined by the positioning caliper 3, the clamping bar 6 clamps the plate, and the worker pushes the plate into the shearing machine to complete the shearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com