Autoinjector

An automatic injector, automatic injection technology, applied in the direction of automatic injector, syringe, hypodermic injection device, etc., can solve the problems of unsatisfactory, the solution is not safe and reliable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

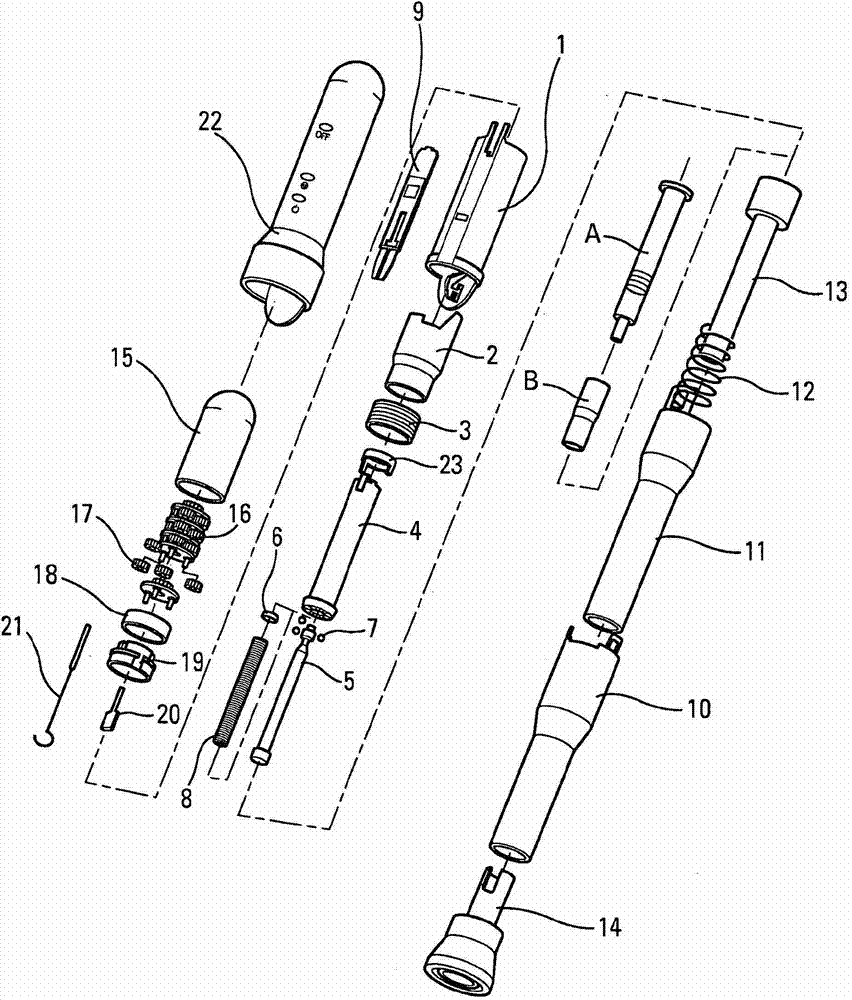

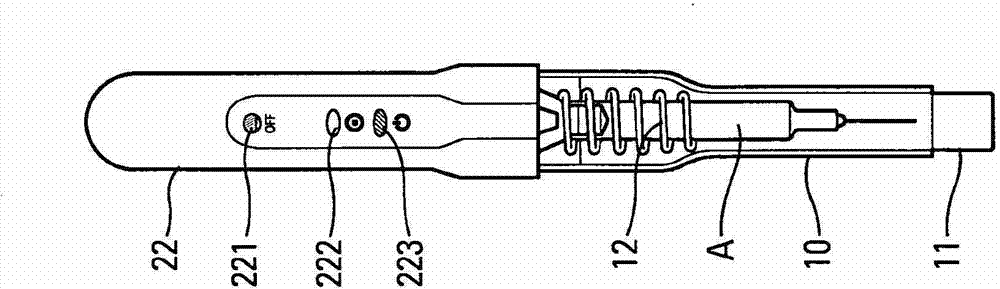

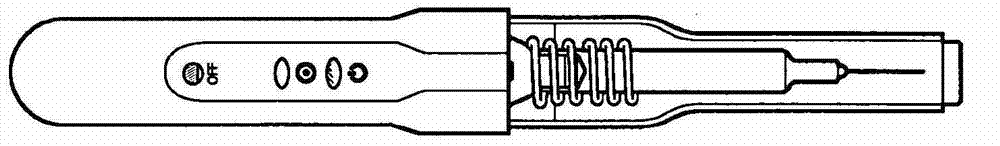

[0083] In the following, the auto-injector will be described with reference to different variants of two advantageous embodiments of the auto-injector. The first implementation is Figure 1 to Figure 46 shown above, the second embodiment is Figures 47 to 74c shown above. It should be noted, however, that an auto-injector, being a complex instrument, includes multiple modules for performing various functions. These different modules can be used individually and independently of each other without necessarily being combined with other modules, and can be used in particular in auto-injectors of shapes other than those shown in the drawings.

[0084] refer to figure 1, the different components of the auto-injector according to the first advantageous embodiment are shown exploded. In this first embodiment, in the order of the reference numbers, the autoinjector has: a central body 1 , a control ring 2 , a piercing spring 3 , a control sleeve 4 , a piston rod 5 , a bearing head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com