Rock-like test piece crack water injection method for frost heave test

A technology for rock specimen and frost heave test is applied in the field of crack water injection of rock specimens used for rock frost heave test, which can solve the problems of increasing experimental workload and experimental cost, difficulty in observing frost heave phenomenon, and the influence of crack freezing force, etc. Achieve the effect of improving water injection efficiency, reducing water loss in cracks, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The rock frost heaving test of the present invention uses the crack water injection method of the rock test piece, comprises the following steps:

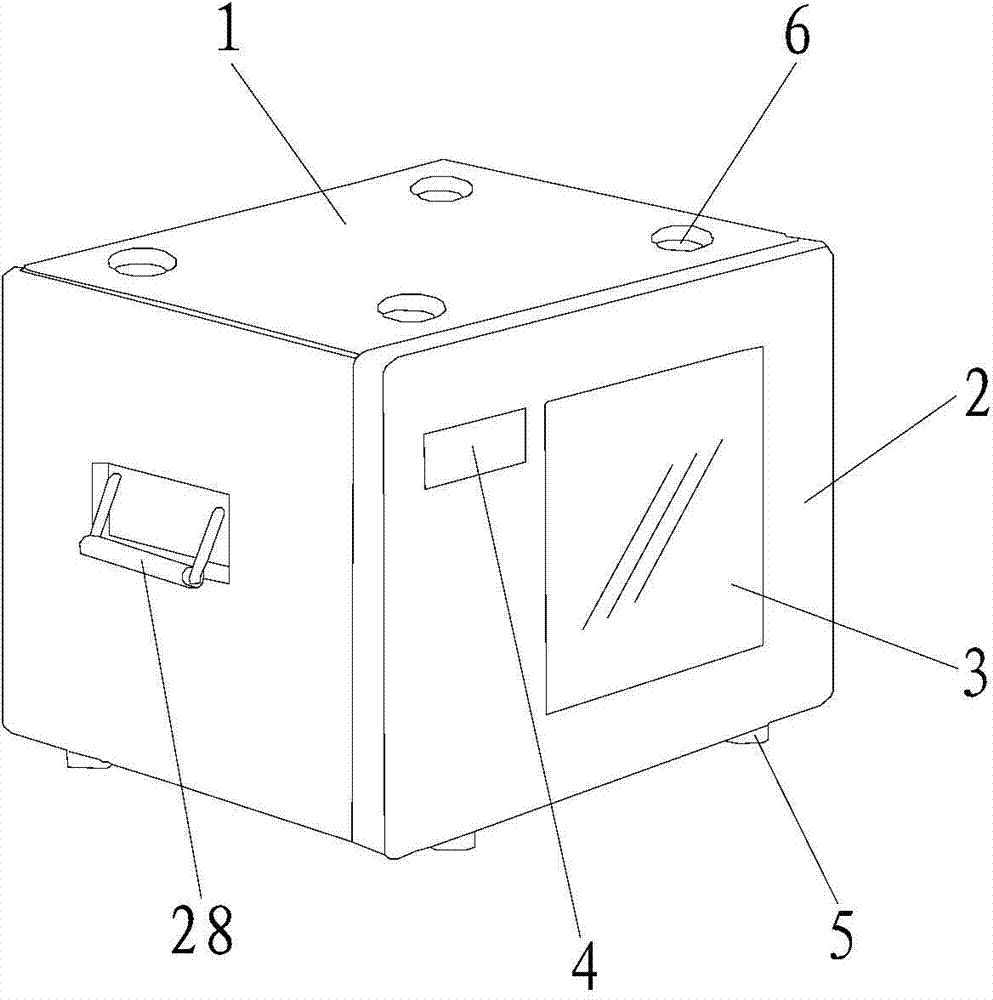

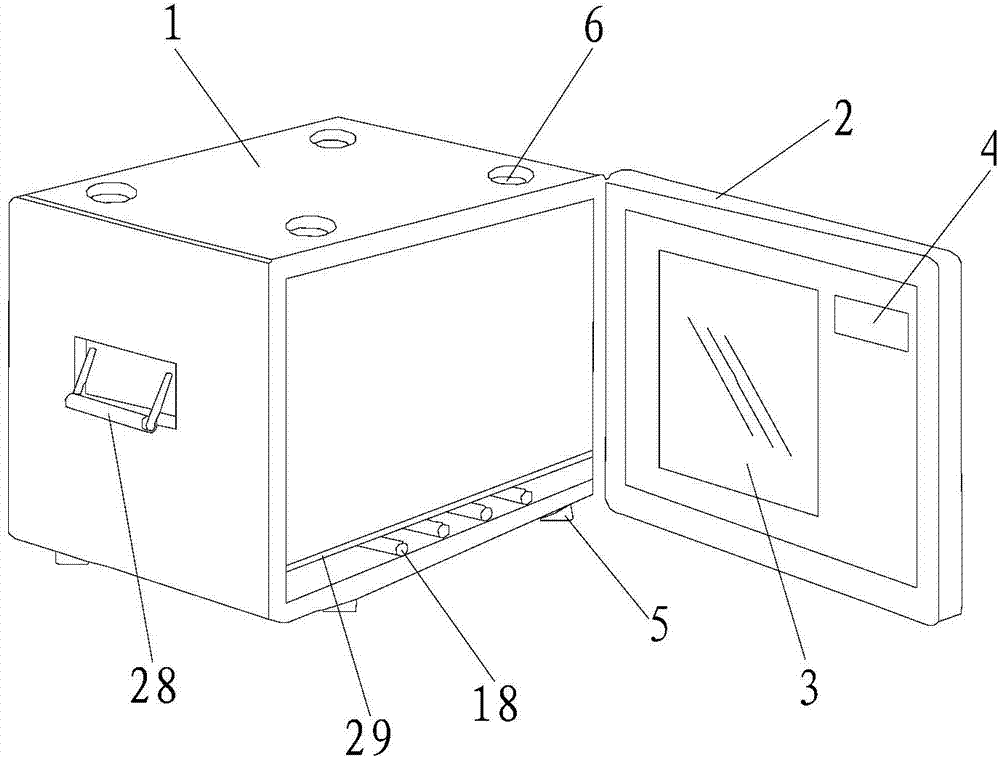

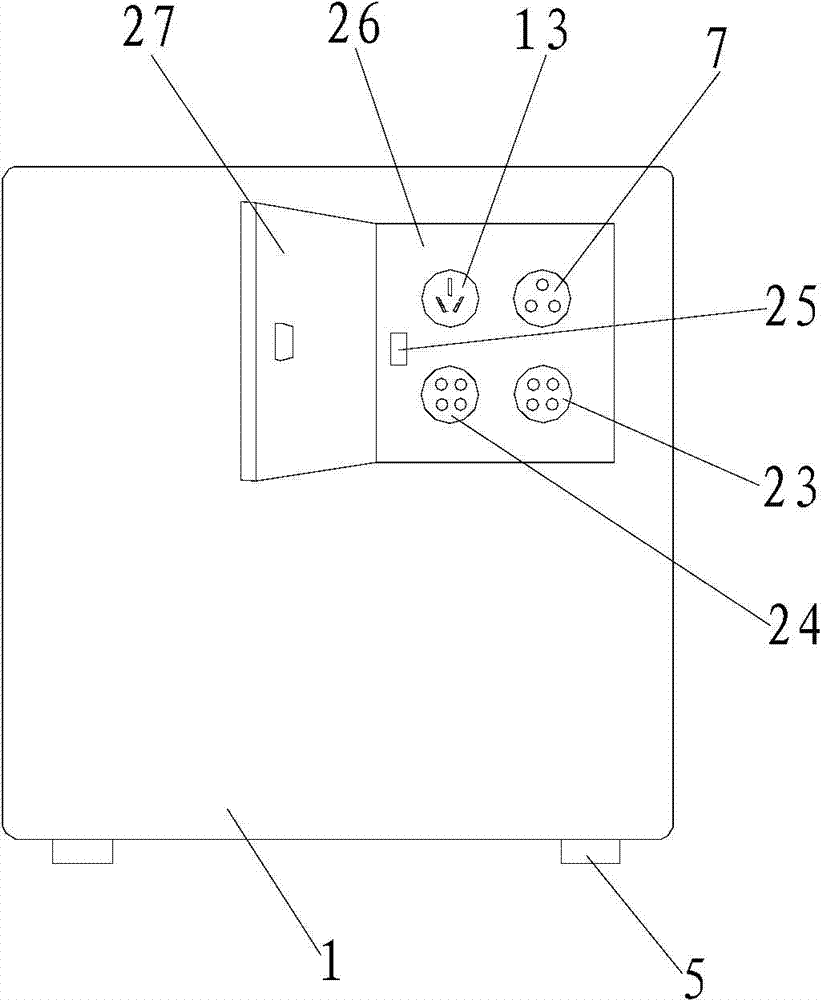

[0057] Step 1. Prepare the non-isothermal control test device for water injection, such as Figure 1 to Figure 5 As shown, the non-isothermal control test device for water injection includes three temperature control test chambers 32 with the same structure, and each temperature control test chamber 32 includes a casing 1 and a door 2 that is rotatably connected to the casing 1. The door 2 is embedded with a glass observation window 3 and a touch-type liquid crystal display 4, and the bottom of the box body 1 is evenly provided with a plurality of installation and fixing protrusions 5, and the top of the box body 1 is evenly provided with a plurality of The installation and fixing groove 6 matched with the fixing protrusion 5 is installed, and the rear wall of the box body 1 is provided with a power input interface 7 for acc...

Embodiment 2

[0071] The rock frost heaving test of the present invention uses the crack water injection method of the rock test piece, comprises the following steps:

[0072] Step 1. Prepare the non-isothermal control test device for water injection, such as Figure 1 to Figure 5 As shown, the non-isothermal control test device for water injection includes three temperature control test chambers 32 with the same structure, and each temperature control test chamber 32 includes a casing 1 and a door 2 that is rotatably connected to the casing 1. The door 2 is embedded with a glass observation window 3 and a touch-type liquid crystal display 4, and the bottom of the box body 1 is evenly provided with a plurality of installation and fixing protrusions 5, and the top of the box body 1 is evenly provided with a plurality of The installation and fixing groove 6 matched with the fixing protrusion 5 is installed, and the rear wall of the box body 1 is provided with a power input interface 7 for acc...

Embodiment 3

[0086] The rock frost heaving test of the present invention uses the crack water injection method of the rock test piece, comprises the following steps:

[0087] Step 1. Prepare the non-isothermal control test device for water injection, such as Figure 1 to Figure 5As shown, the non-isothermal control test device for water injection includes three temperature control test chambers 32 with the same structure, and each temperature control test chamber 32 includes a casing 1 and a door 2 that is rotatably connected to the casing 1. The door 2 is embedded with a glass observation window 3 and a touch-type liquid crystal display 4, and the bottom of the box body 1 is evenly provided with a plurality of installation and fixing protrusions 5, and the top of the box body 1 is evenly provided with a plurality of The installation and fixing groove 6 matched with the fixing protrusion 5 is installed, and the rear wall of the box body 1 is provided with a power input interface 7 for acce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com