Bridge gap residue removal device using water cooling and heat dissipation and using method thereof

A cleaning device, water cooling and heat dissipation technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of slag cannot be removed, low efficiency, poor safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

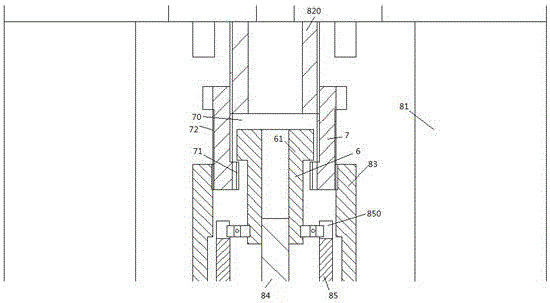

[0013] Combine below Figure 1-3 The present invention will be described in detail.

[0014] According to an embodiment of the present invention, a bridge gap residue removal device using water cooling and heat dissipation is used to remove residues in gaps in bridges 9, such as bridge expansion joints, and includes a support plate 8, which is used for It spans the gap and is fixedly connected to the lower end of the erected support 81. The upper end of the erected support 81 is fixedly connected to the drive motor 82. The drive motor 82 is power-coupled with the drive sleeve 820, and the drive sleeve 820 The outer surface of the outer surface is slidably connected with the upper part of the inner hole of the sliding sleeve 7 through key fit, and the lower part of the inner hole of the sliding sleeve is provided with a radially inwardly extending spline protrusion 71, the sliding sleeve The inner hole of the barrel is a cavity 70 above the spline protrusion 71, and the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com