Penetrating selective plugging agent and preparation method and application method thereof

A selective and plugging technology, applied in chemical instruments and methods, earth-moving drilling, wellbore/well components, etc., can solve the problem of non-selective water plugging technology, unclear water output horizon, packer failure, loss of reserves and other problems, to reduce the risk of encountering other ions, improve the blocking ability, and strengthen the blocking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment relates to several groups of permeation selective plugging agents, and the formulations are shown in the following table:

[0030]

[0031] According to the formula in the above table, first add retarder and coagulant to clear water, stir to dissolve; add viscosifier and stabilizer under high-speed stirring at a speed of 5000r / min to make the dispersion even; finally add the main agent, Under the high-speed stirring of 13000r / min, the permeation-selective blocking agent in suspension state was obtained.

Embodiment 2

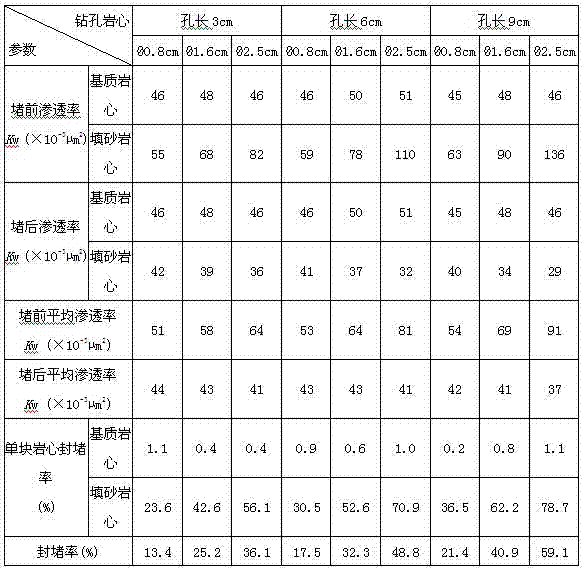

[0033]This embodiment relates to the detection of the plugging effect of the permeable selective plugging agent of Embodiment 1, and the permeability and plugging rate are detected by the core displacement experiment. The experimental core is a quartz sand epoxy resin cemented artificial core. The geometric dimensions are: height × width × length = 4.5 × 4.5 × 15cm. In order to simulate the formation of large pores in the formation, holes are drilled along the length of the core. The depth of the holes is 3cm and 6cm respectively. and 9cm, the hole diameters are 0.8cm, 1.6cm and 2.5cm respectively, fill the holes with sand, and the sand particle size is between 35-40 mesh. The injection rate during the experimental water flooding process was 0.6mL / min.

Embodiment 21

[0035] This embodiment relates to a single rock core experiment, and the operation steps are as follows:

[0036] ①. Core water permeability measurement before and after drilling sand filling;

[0037] ②. inject embodiment 1.1 permeation selective blocking agent;

[0038] ③. Place the core under the experimental conditions for 24 hours;

[0039] ④. Water flooding until the pressure is stable, then calculate the permeability and plugging rate.

[0040] The experimental results are shown in the table below:

[0041]

[0042] It can be seen from the above table that under the same pore diameter, the plugging rate increases with the increase of the pore length; under the same pore length, the plugging rate increases with the increase of the pore diameter. When the pore length is 9cm and the pore diameter is 2.5cm, the plugging rate can reach 90.9% after waiting for 24 hours, which shows that the permeable selective plugging agent of the present invention has good plugging ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole length | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com