Spraying device and spraying method thereof

A technology of spraying device and nozzle, applied in the direction of spraying device, etc., can solve the problems of high labor intensity, low efficiency and poor effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

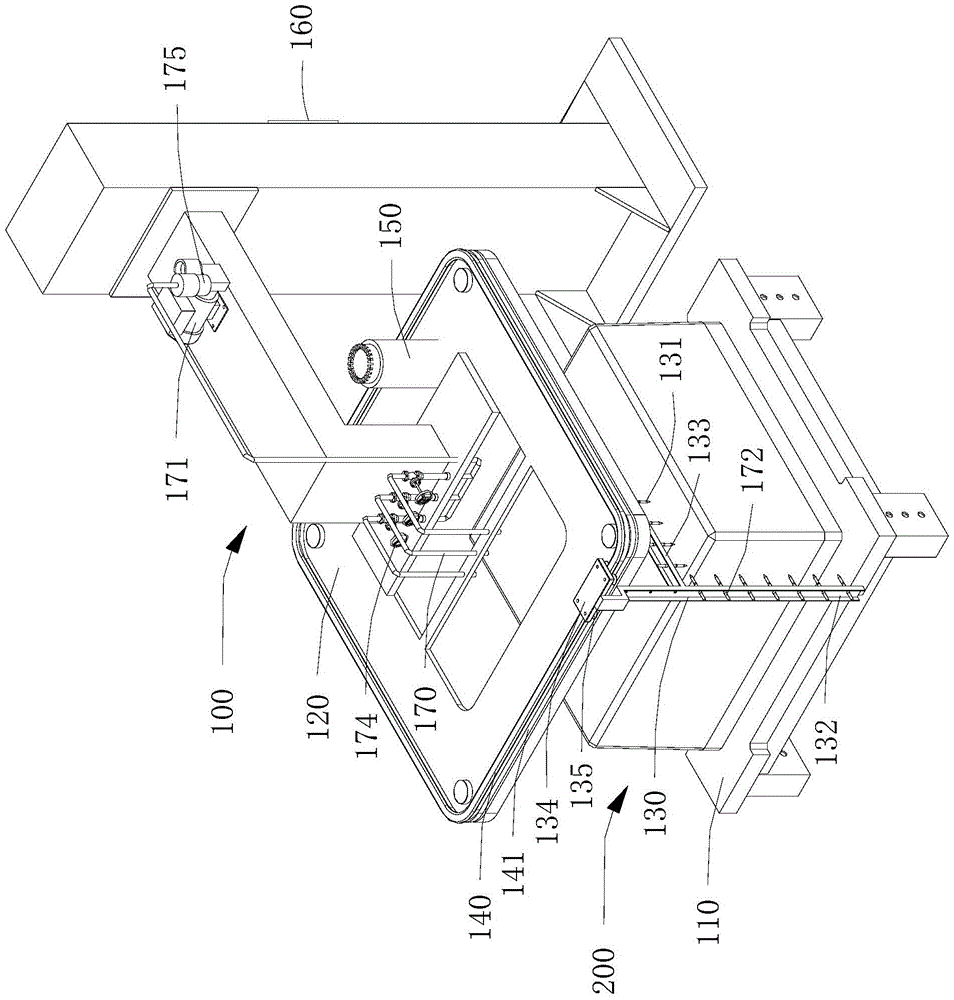

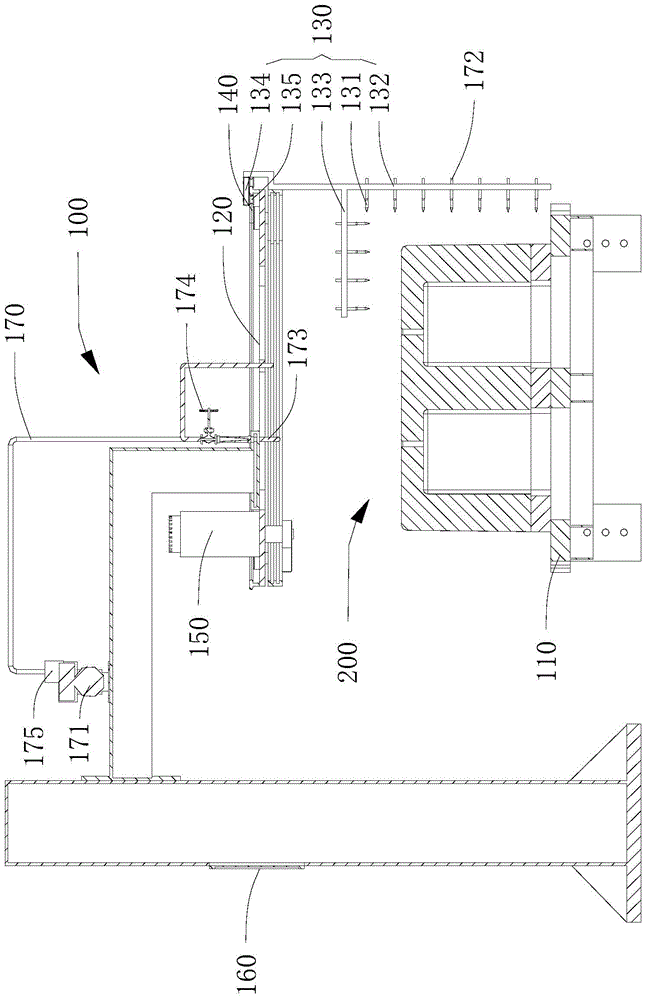

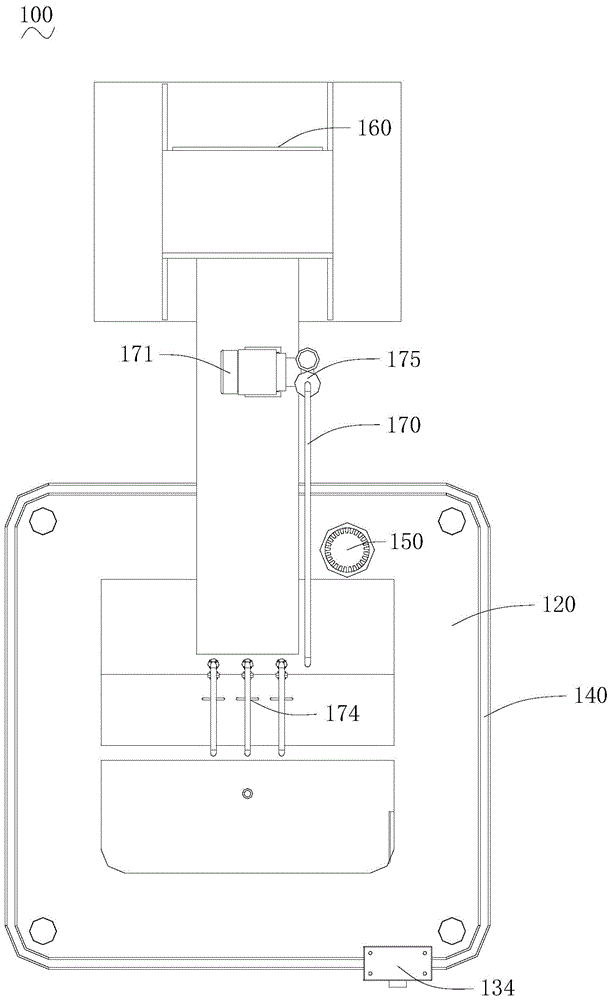

[0034] Please refer to figure 1 , this embodiment discloses a spraying device 100 , the spraying device 100 includes a supporting platform 110 , a working platform 120 and a cantilever 130 suspended on the working platform 120 .

[0035] On the support platform 110 is placed a workpiece 200 that needs to be treated by air jet or liquid spray. In this embodiment, the workpiece 200 is a plaster mold.

[0036] The working platform 120 is arranged opposite to the supporting platform 110 , and a guide rail 140 is arranged on the working platform 120 , and the guide rail 140 is detachably fixed on the working platform 120 by conventional structures such as screws and bolts. For the detachable connection structure between the guide rail 140 and the working platform 120 , different types of guide rails 140 can be selected according to the requirements of the actual structure of the workpiece 200 . For example, you can choose guide rails with closed structure (that is, ring structure)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com