Ampoule machine neck compression cam

A technology of ampoule machine and cam, which is applied in the direction of measuring devices, instruments, and material analysis through optical means, which can solve the problems affecting the shape of products, the deformation of neck pressing cams, and the image of production enterprises, so as to achieve reliable and inferior products and avoid inferior quality The effect of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

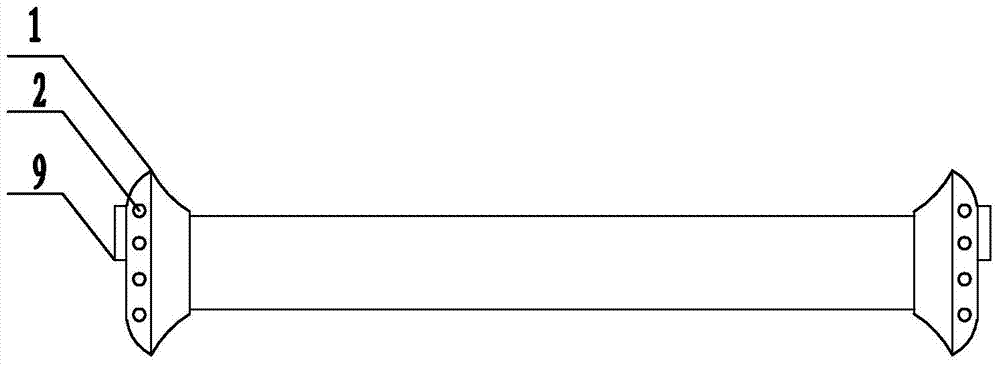

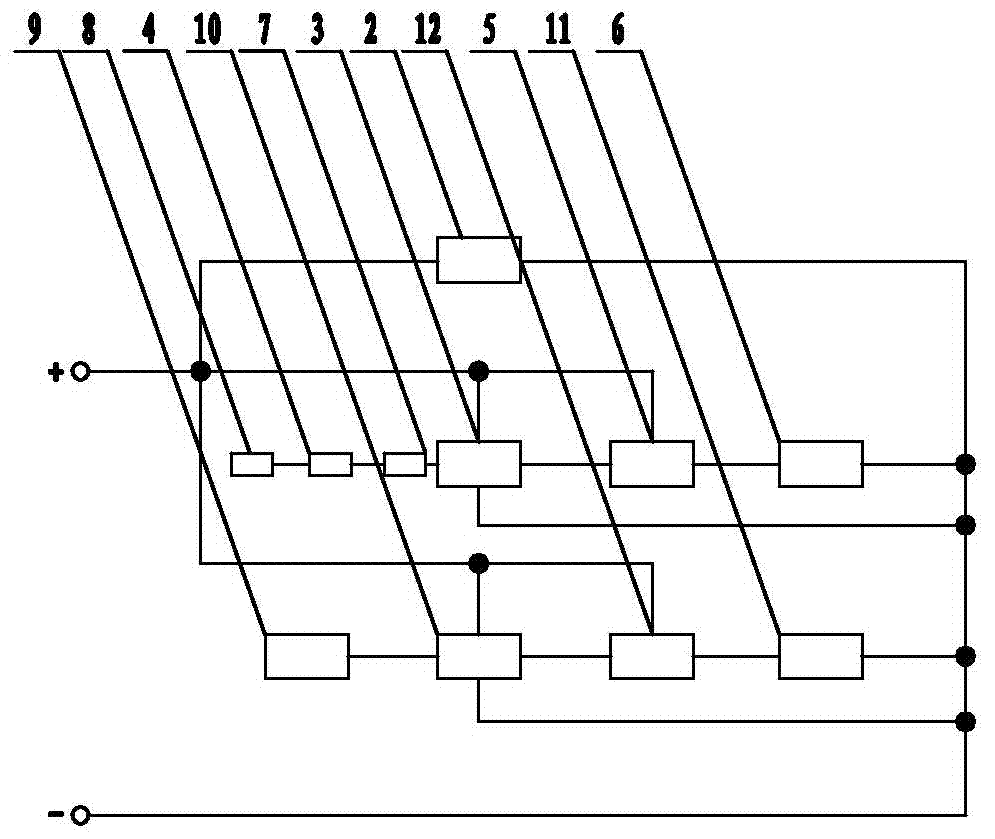

[0014] Embodiment 1: as figure 1 and figure 2 As shown, the neck pressing cam of the ampoule machine according to the present invention includes a neck pressing cam 1, which is a hollow structure, a laser light 2 is provided on the surface of the neck pressing cam 1, and a controller 3 is arranged inside the neck pressing cam 1. Photoelectric converter 4, relay 5, alarm horn 6 and analog-to-digital converter 7, a laser receiver 8 is arranged below the product pressed by the neck cam 1, and the signal output end of the laser receiver 8 is connected to the signal receiving end of the photoelectric converter 4 , the signal sending end of the photoelectric converter 4 is connected to the analog-to-digital converter 7, the signal sending end of the analog-to-digital converter 7 is connected to the signal receiving end of the controller 3, the laser light 2 and the controller 3 are connected to the power supply through the air switch, and the alarm horn 6 The power terminal of the...

Embodiment 2

[0015] Embodiment 2: On the basis of the structure of Embodiment 1, the neck-pressing cam of the ampoule machine is provided with a distance sensor 9 at both ends of the neck-pressing cam 1, and a bulb 11, a contactor 12 and a distance sensor 9 are arranged inside the neck-pressing cam 1. In the controller 10, the output end of the distance sensor 9 is connected to the input end of the distance controller 10, the output end of the distance controller 10 is connected to the control end of the contactor 12, and the bulb 11 is connected to the power supply through the power end of the contactor 12.

[0016] Operation steps and working principle:

[0017] When the ampoule produced has no cracks, the optical power of the laser lamp 2 received by the laser receiver 8 is constant, but when there are cracks or bubbles, the laser is affected by the refraction of the cracks or bubbles, and the power will change greatly and continuously. After the signal is converted by the photoelectric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com