Telescopic outrigger device for tunnel bridge erecting machine

A bridge erecting machine, telescopic technology, applied in the field of telescopic outrigger devices for tunnel bridge erecting machines, can solve the problems of outriggers and main girders, heavy construction workload, long construction period, etc., to achieve fast operation, The effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

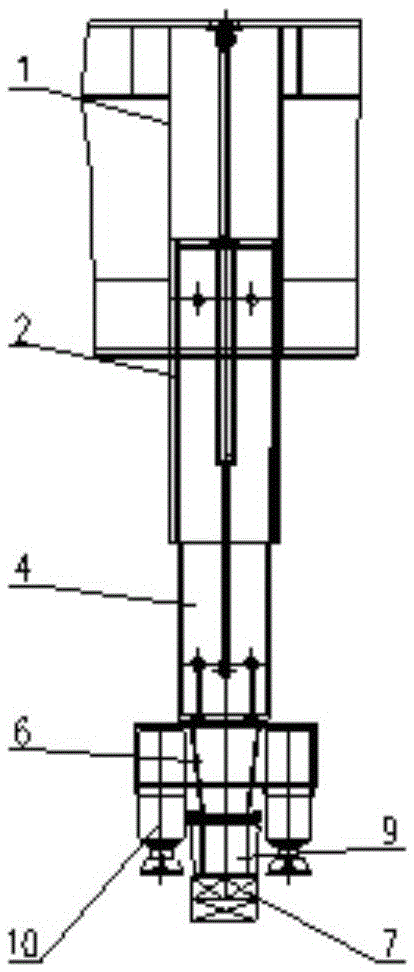

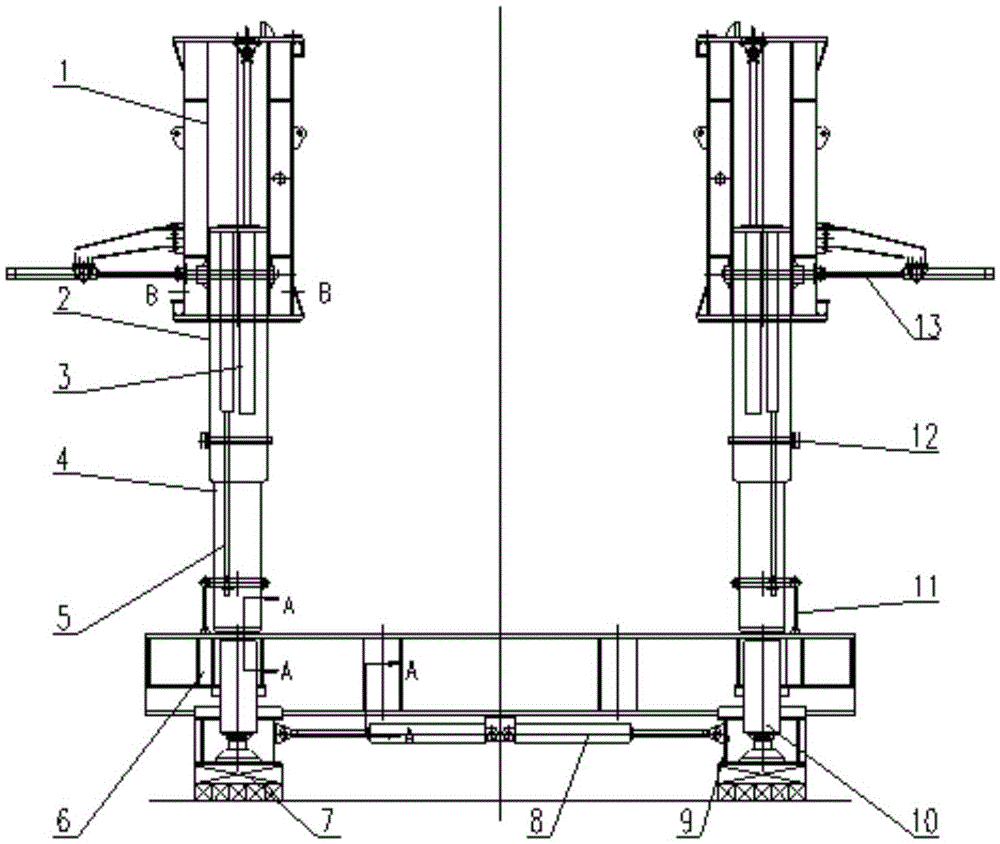

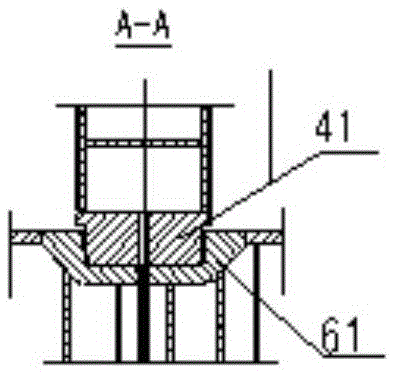

[0027] see Figure 1 to Figure 6 , shows the telescopic outrigger device for the tunnel bridge erecting machine of the present invention.

[0028] The telescopic outrigger device for the tunnel bridge erecting machine includes two sets of primary telescopic structures, two sets of secondary telescopic structures and lower cross-links 6 .

[0029] Each of the first-level telescopic structures is respectively arranged under the main beam outer column 1 of the bridge erecting machine, each of the second-level telescopic structures is arranged under the first-level telescopic structure, and the lower cross-link 6 is arranged between two sets of second-level telescopic structures. below.

[0030] Wherein, the first-level telescopic structure includes a first-level telescopic column 2 and a first-level telescopic oil cylinder 3, and the first-level telescopic column 2 is a hollow casing, the upper end of which can be inserted into the hollow groove of the outer column 1 of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com