A railway track laying machine capable of carrying load and moving across the line

The technology of a track laying machine and a traversing mechanism is applied in the field of railway track laying equipment and railway track laying machines. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

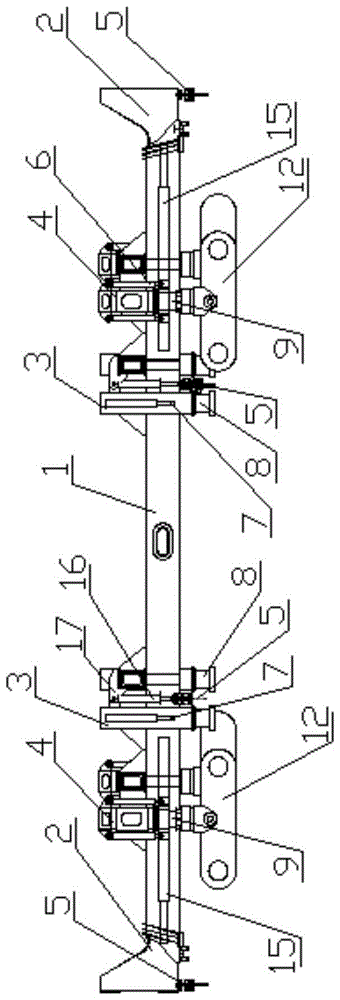

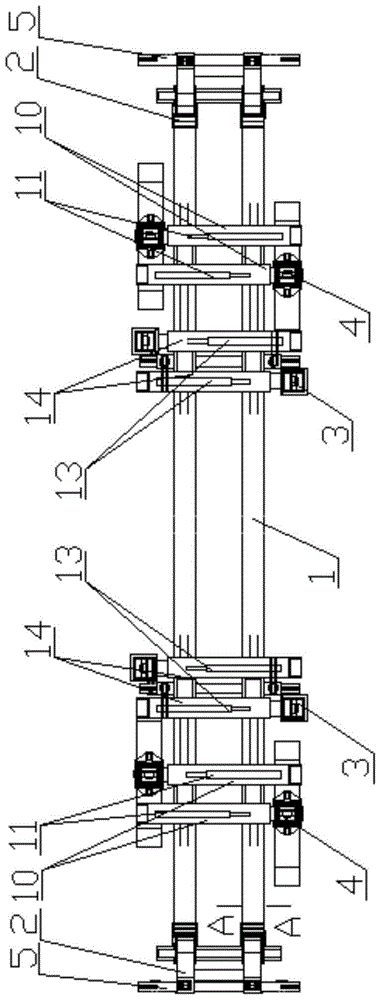

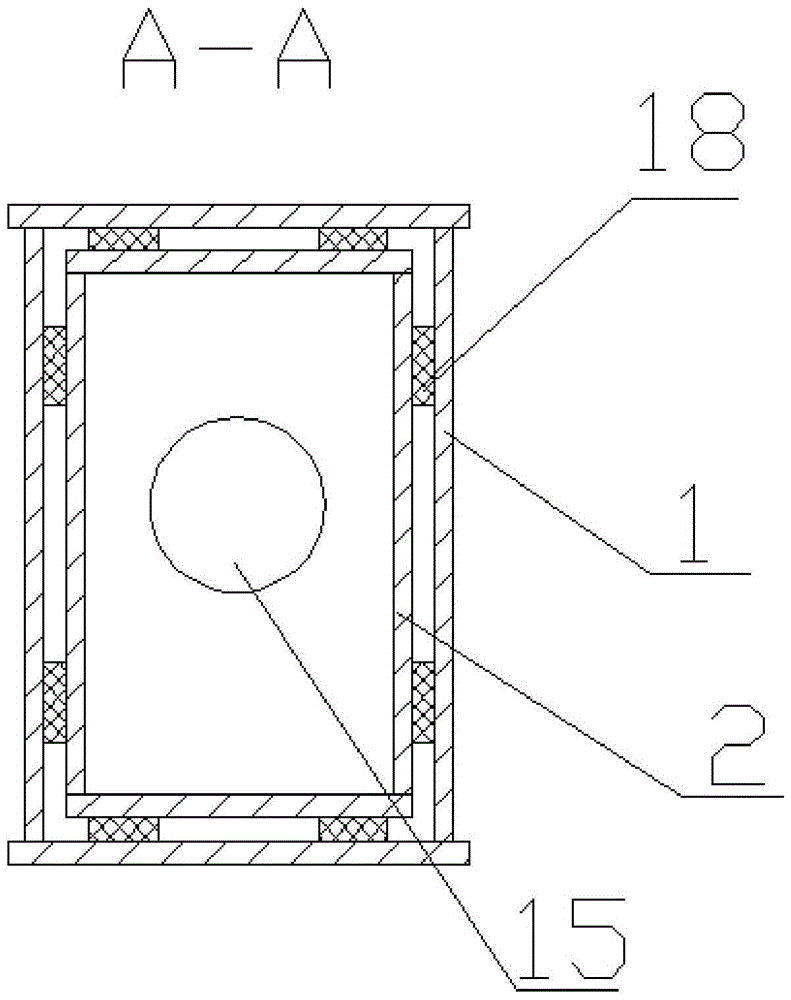

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0018] The present invention is a railway track-laying machine capable of laterally moving across the line with a load, comprising a main frame, a telescopic arm, a lateral moving mechanism, a running mechanism, a spreader, a hydraulic system, and an electrical control system. The main frame 1 consists of two horizontal longitudinal beams It is connected with a small beam; a plurality of spreaders 5 are symmetrically connected to the center of the main frame 1, and the center of gravity of each spreader falls on the longitudinal centerline of the horizontal longitudinal beam of the main frame; The oil cylinders 15 are respectively arranged at both ends of the horizontal longitudinal beam of the main frame 1, and can be telescopically moved along the horizontal longitudinal beam through the telescopic oil cylinder 15; The outer running beam of each set of running mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com