High-speed strong dehydration cylinder paper making machine

A paper machine, high-speed technology, applied in the field of high-speed strong dehydration cylinder paper machine, can solve the problems of paper sheets cannot be formed, low speed, etc., to ensure the dehydration rate, reduce production costs, and promote the effect of improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

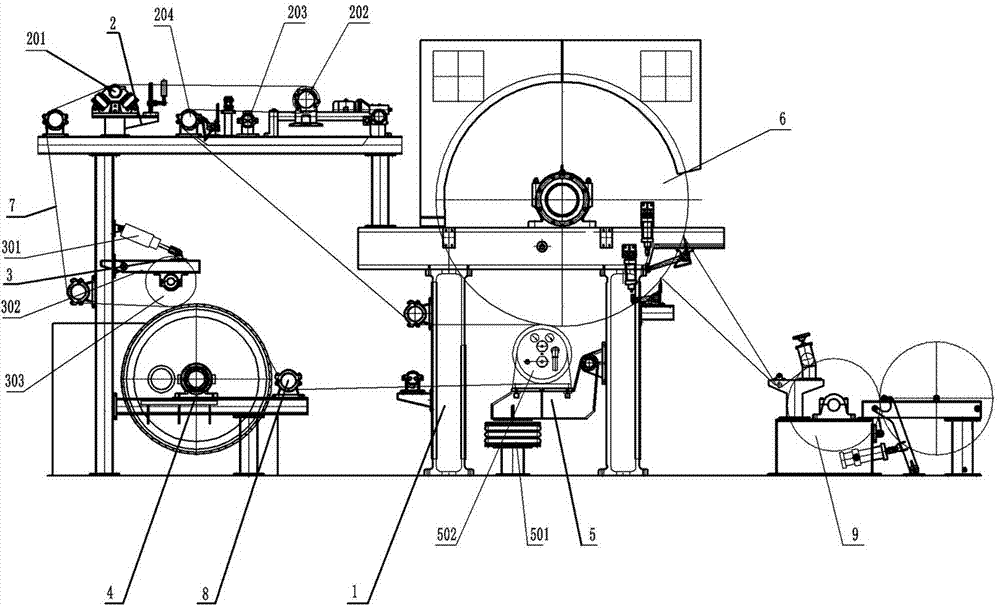

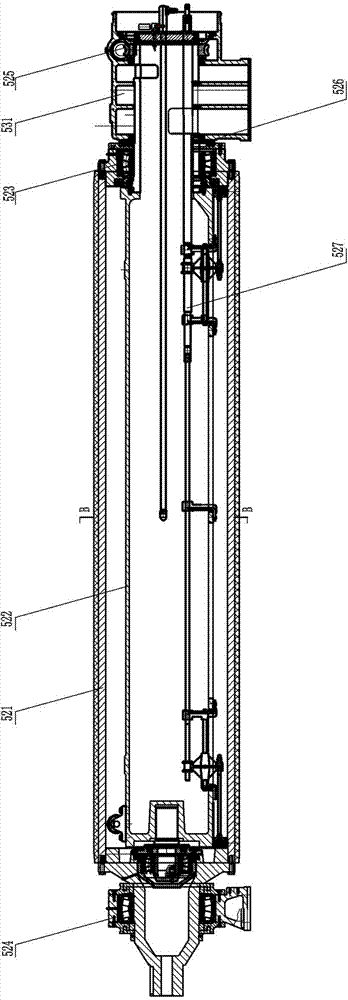

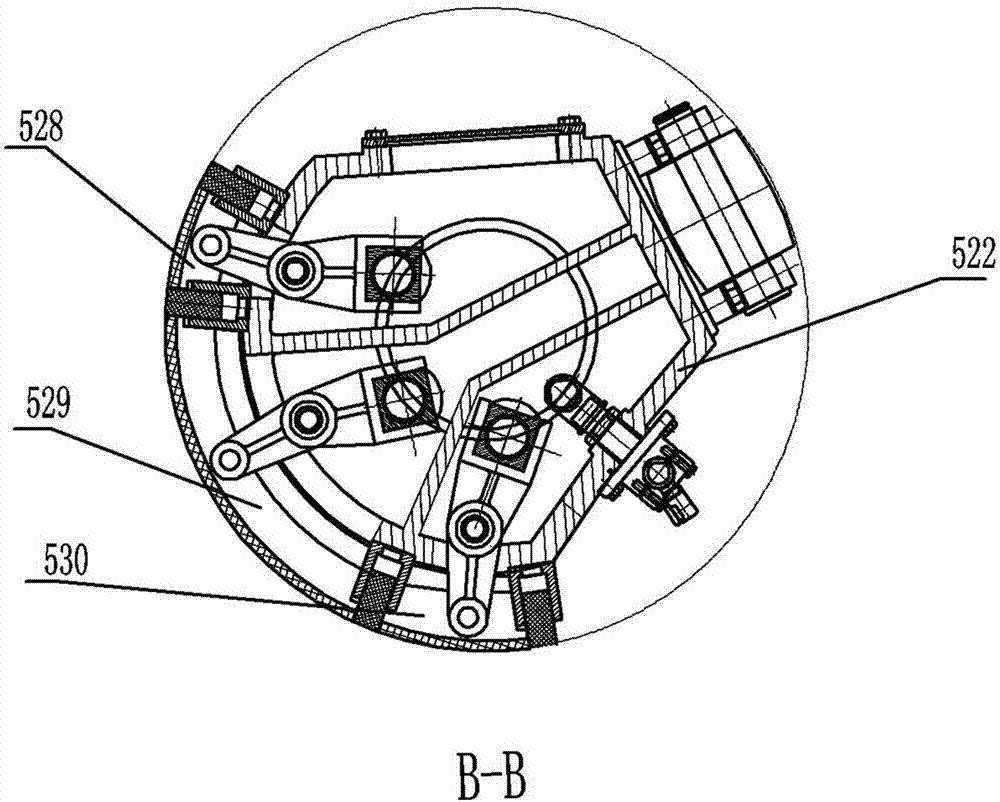

[0025] The high-speed strong dewatering cylinder paper machine of the present invention comprises a frame 1, a felt optimization mechanism 2, a couch roll mechanism 3, a mesh cage mechanism, an idler mechanism 5, a drying cylinder mechanism 6 and a blanket 7, and the blanket optimization mechanism 2 is fixed Set on one side of the top of the frame 1, the drying cylinder mechanism 6 is fixedly installed on the other side of the top of the frame 1, the mesh cage mechanism is fixedly installed below the felt optimization mechanism 2, and the couch roller mechanism 5 is hingedly installed above the mesh cage mechanism , and the roller mechanism 3 and the cage mechanism are opposite to the roller; the idler mechanism 5 is fixedly installed on the frame 1 below the drying cylinder mechanism 6, and the idler mechanism 5 and the drying cylinder mechanism 6 are opposite to the roller, and the blanket 7 Sequentially rotate through blanket optimization mechanism 2, couch roller mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com