Drilling device and positioning assembly

A drilling device and positioning component technology, applied in the field of ships, can solve the problems of low drilling accuracy and complicated drilling equipment, and achieve the effects of improving construction efficiency, simple structure and portable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The invention provides a drilling device, which is used for drilling shell plates. Among them, according to actual operation requirements, at least one hole to be drilled is marked on the shell plate, and the marking line on the hole to be drilled completely matches the mounting hole on the steel structure to be installed correspondingly, so that the shell plate can be drilled smoothly after the drilling operation is completed. Install.

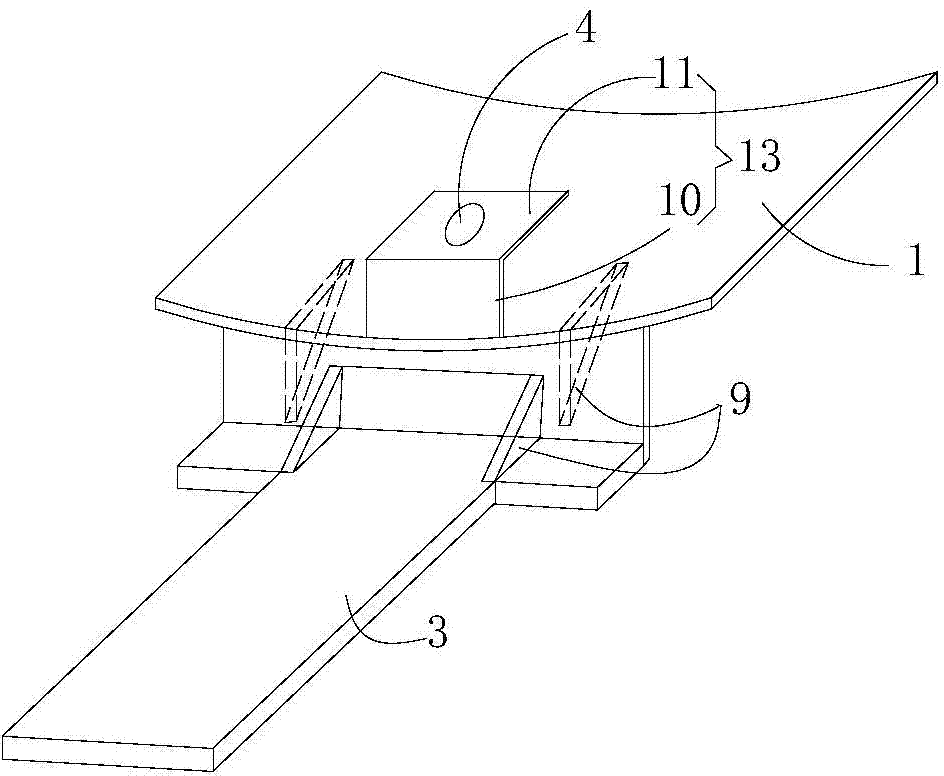

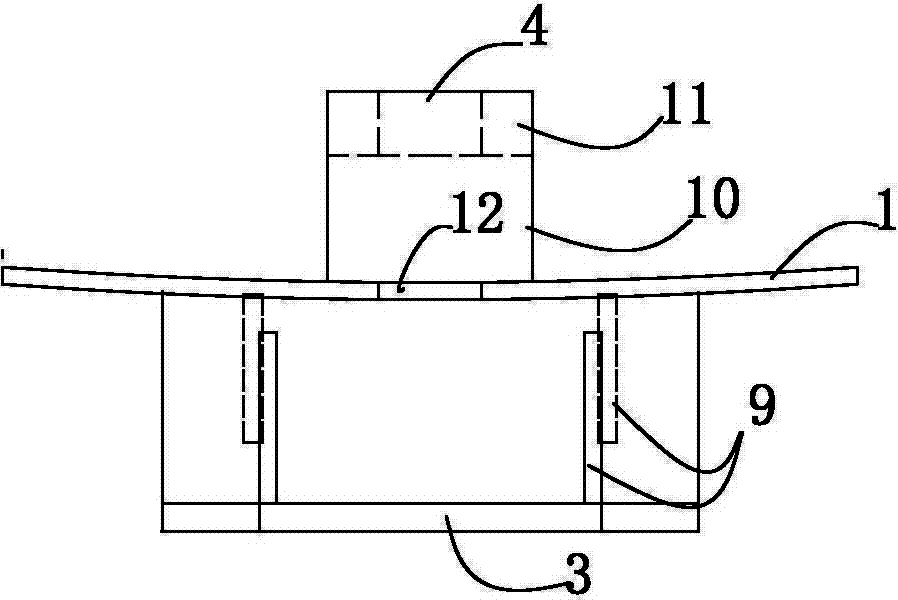

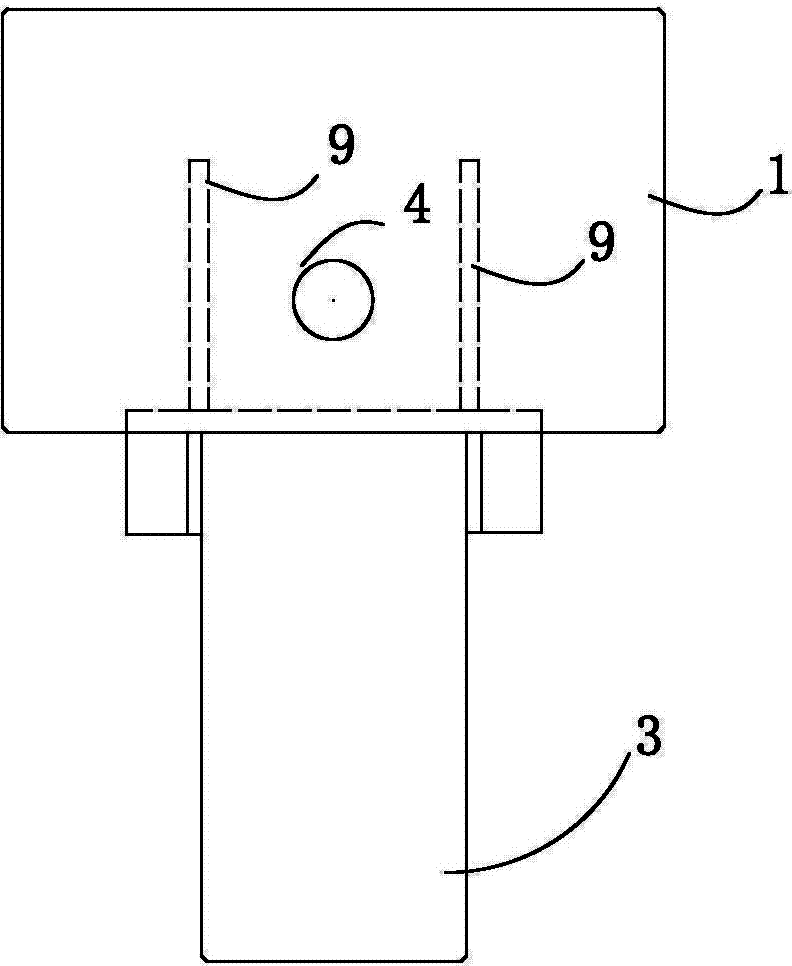

[0057] Specifically, see Figure 1-5 , The drilling device includes: a positioning component and a drilling component.

[0058] further,

[0059] The positioning assembly may at least include: a bonding plate 1 having an upper surface and a lower surface, a clamping piece 13 and a positioner 2 . Wherein, the upper surface of the bonding plate 1 is bonded to the shell plate to be drilled, and the shape and structure of the bonding plate 1 can be adaptively adjusted according to the shape and structure of the shell plate to be drilled...

Embodiment 2

[0072] Based on Embodiment 1 of the present invention, Embodiment 2 of the present invention provides a positioning assembly, including: a bonding plate, the bonding plate is bonded to the shell plate, and a first through hole is opened on the bonding plate, The first through hole is fitted correspondingly to the hole to be drilled; a clamping member, the clamping member is fixed on the bonding plate, so as to clamp the shell through the clamping member and the bonding plate plate, and a second through hole is opened on the clamping member, the second through hole is coaxially distributed with the first through hole, and the hole to be drilled is located in the first through hole, the second through hole Between the through holes; a locator, the locator is placed in the second through hole.

[0073] In Embodiment 2 of the present invention, the connection relationship, positional relationship and working principle of each component are completely the same as those in Embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com