A method for real-time analysis of smoke from online tobacco products

A technology for real-time analysis and tobacco products, applied in the direction of analyzing materials, material separation, measuring devices, etc., can solve problems such as cumbersome process, flue gas dynamic properties, flue gas instability, collection, separation, extraction and enrichment difficulties, etc., to overcome The effect of discrimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

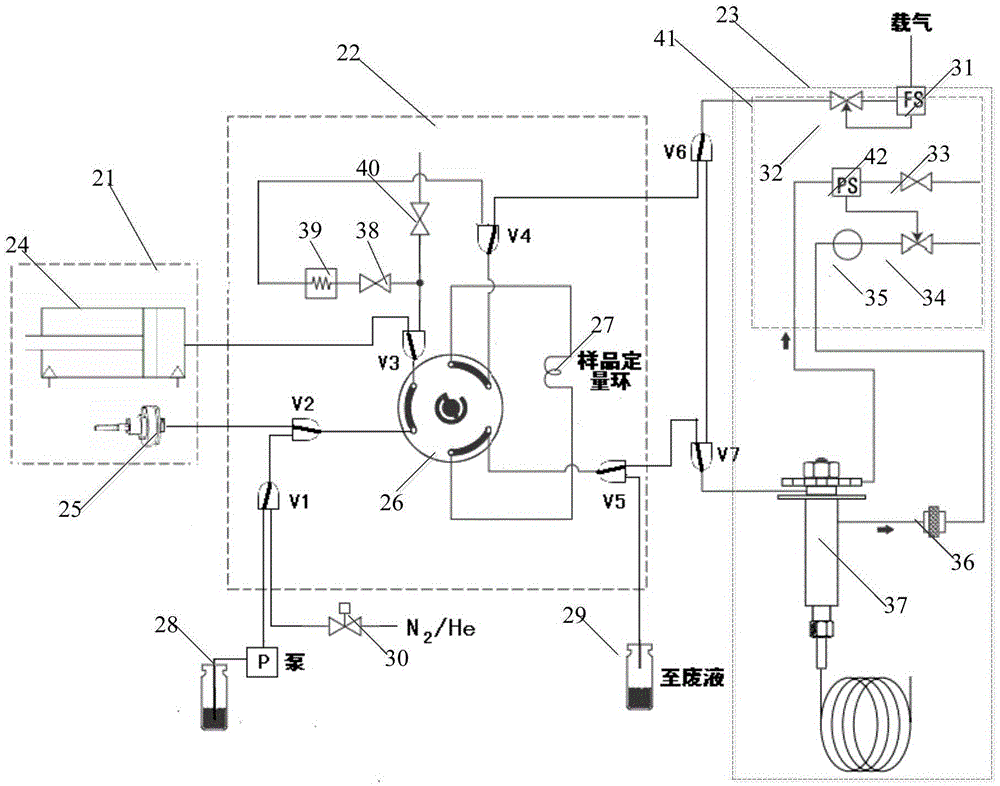

[0148] Using a single-channel linear smoking machine as the smoking machine, the volume of the quantitative loop in the online pollution cleaning injector is 3mL, the cleaning solvent is chromatographically pure chloroform, and the flushing gas is nitrogen or helium (N 2 or He). Gas chromatography mass spectrometer (GC / MS) was the analytical detector. The temperature of the cigarette holder is set to 120°C, and a 44mm Cambridge filter is clamped in the cigarette holder.

[0149] Register the sample information in the GC / MS workstation control software (ie, the flue gas analysis control unit), set the analysis method conditions, and enter the ready analysis state. Operate the smoking machine to make it ready for smoking.

[0150] Insert the cigarette to be tested into the cigarette holder. Set the suction parameters in the control center (external controller) software, including the number of suction ports (the third port), the number of solvent cleaning times (2 times), N ...

Embodiment 2

[0158] The first embodiment is repeated according to the same steps described above, but the cigarette holder is empty, that is, no filter sheet or filter paper of any material is clamped. Cigarette smoke samples can be subjected to suction, automatic constant temperature quantitative sampling, GC or GC / MS analysis according to the selected program to obtain a suitable chromatogram.

Embodiment 3

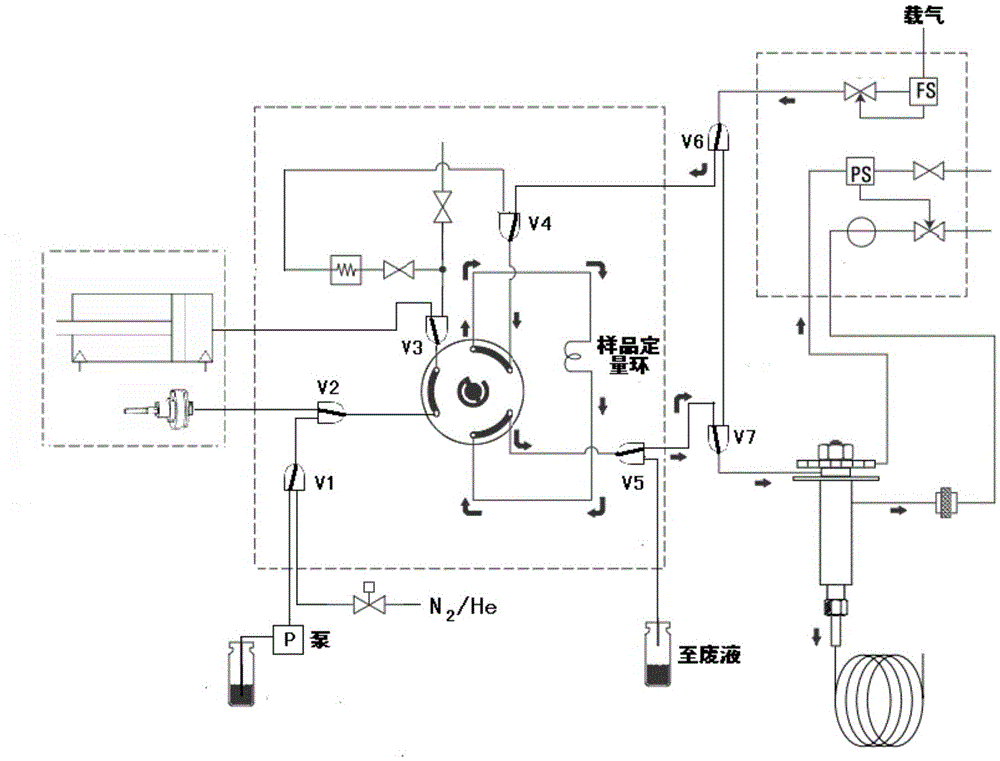

[0160] Set up the instrument according to the following conditions for on-line analysis of cigarette mainstream smoke components:

[0161] 1) Temperature balance:

[0162] Set the smoke holder, injector, transfer line to a fixed temperature value and wait for them to equilibrate.

[0163] Typically, the smoke holder is 50°C, the sampler is 100°C, and the transfer line is 150°C, so as to ensure that the high boiling point components in the flue gas do not liquefy and condense.

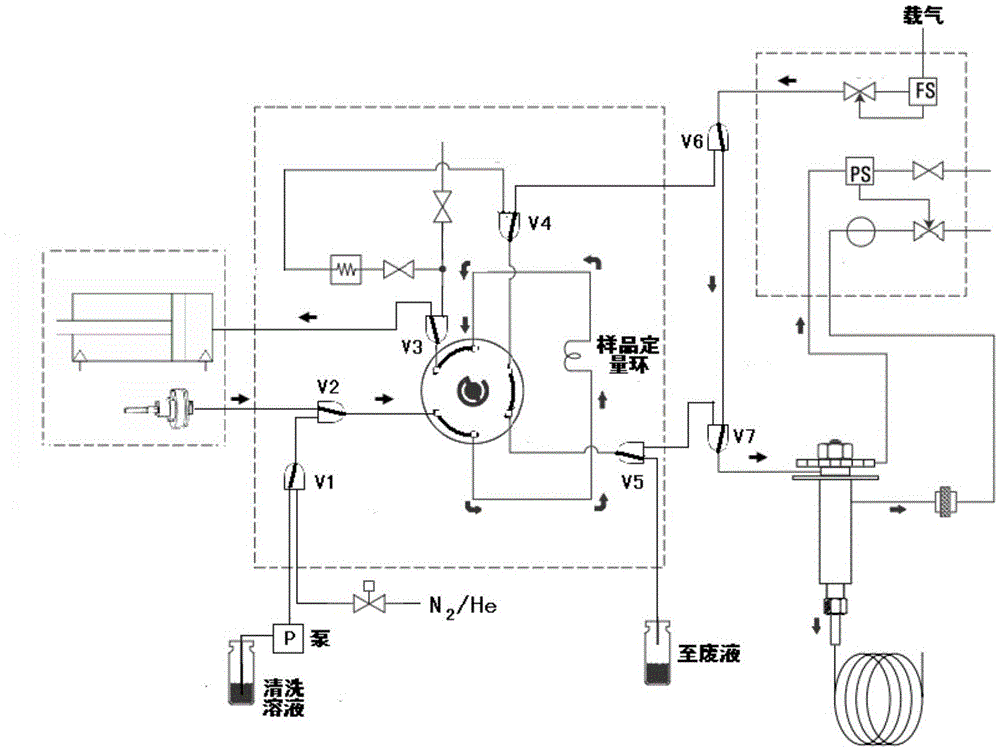

[0164] 2) Sample suction:

[0165] The cigarette holder is directly connected to the sample inlet of the gas sampler, and the suction device is connected to the exhaust gas outlet of the gas sampler for suction. The suction device may comprise a linear smoking machine, a rotary smoking machine, a single channel smoking machine or other types of smoking machines. A typical single-channel smoking machine LM-1 such as Borgwaldt. Suction capacity, number of suction ports, suction duration, and suction f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com