Rigidity change device and method applicable to vortex-induced vibration testing system

A test system, vortex-induced vibration technology, used in fluid dynamics tests, measuring devices, testing of machine/structural components, etc. There are quite a lot of problems, such as consuming a lot of time, to achieve the effect of simple and convenient pre-balancing work, reducing test costs and test cycles, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

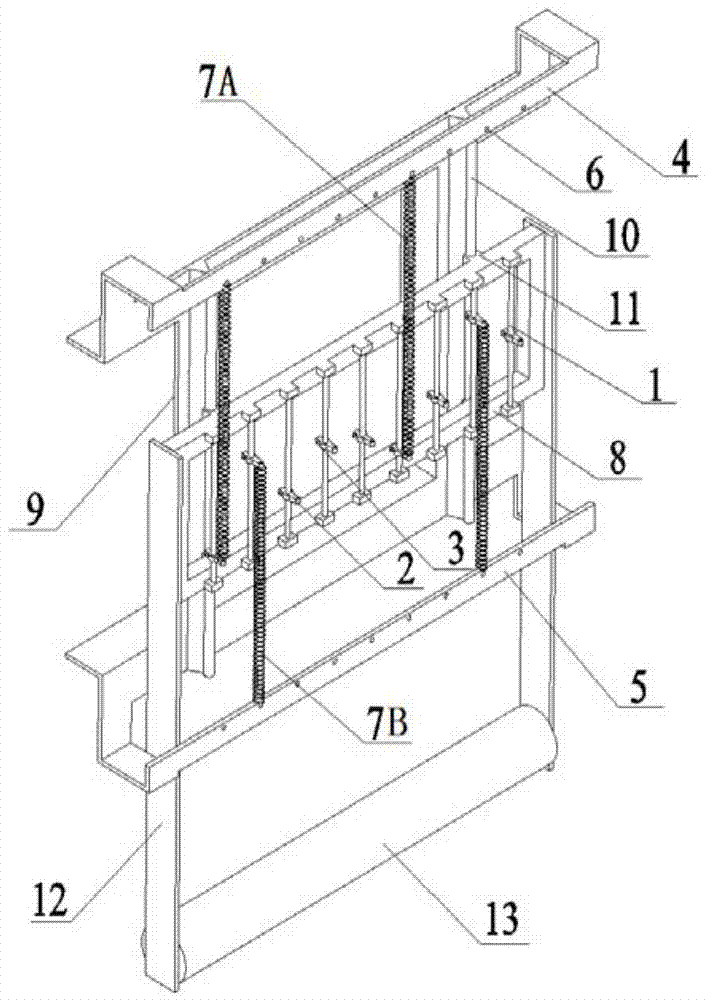

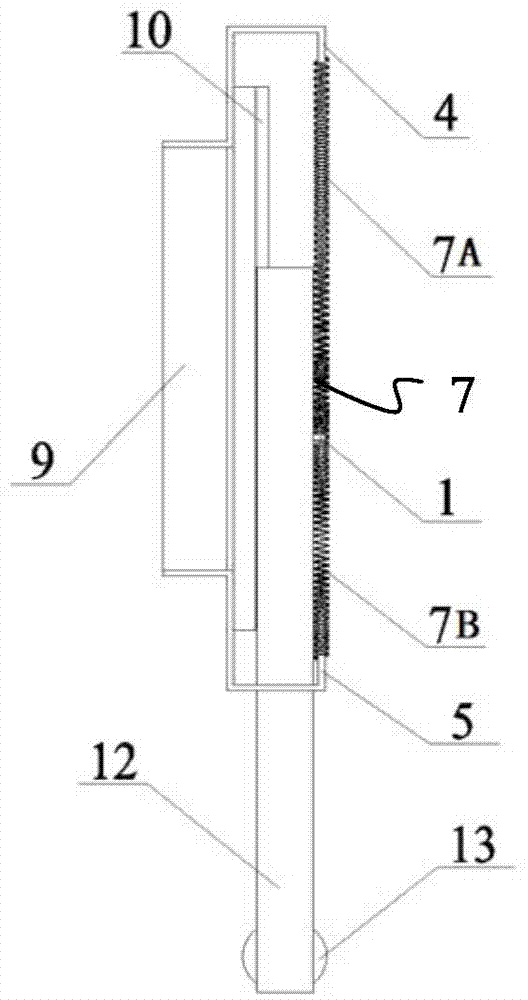

[0042] attached by figure 1 And attached figure 2 It can be seen that the present invention includes a hanging track 1, a hook 2, a buckle 3, an upper hanging beam 4, a lower hanging beam 5, a hanging hole 6, a tension spring 7, a sliding frame 8, a bearing frame 9, and a sliding track 10 . The hanging rail 1 and the hook 2 are made of stainless steel, and the upper hanging beam 4 and the lower hanging beam 5 are made of steel; One correspondence; the hanging track 1 is arranged on the sliding frame 8 at intervals, and the hook 2 is moved and fixed on the hanging track 1 through the buckle 3; the upper hanging beam 4 and the lower hanging beam 5 are respectively fixed on the bearing Above and below the frame 9, the hanging holes 6 are arranged on the upper hanging beam 4 and the lower hanging beam 5 at intervals according to corresponding positions, stric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com