A Double Ball Measurement Method for Counterbore Angle

A measurement method and height measurement technology, applied in the field of double-ball measurement method of countersunk hole angle, to achieve the effect of simple measurement tool, improved accuracy, and convenience for operators to master

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0052] In addition, the bottom of the counterbore mentioned in the embodiments of the present invention refers to the cylindrical part of the conical counterbore.

[0053] The present invention will be described in detail below with reference to the accompanying drawings and examples.

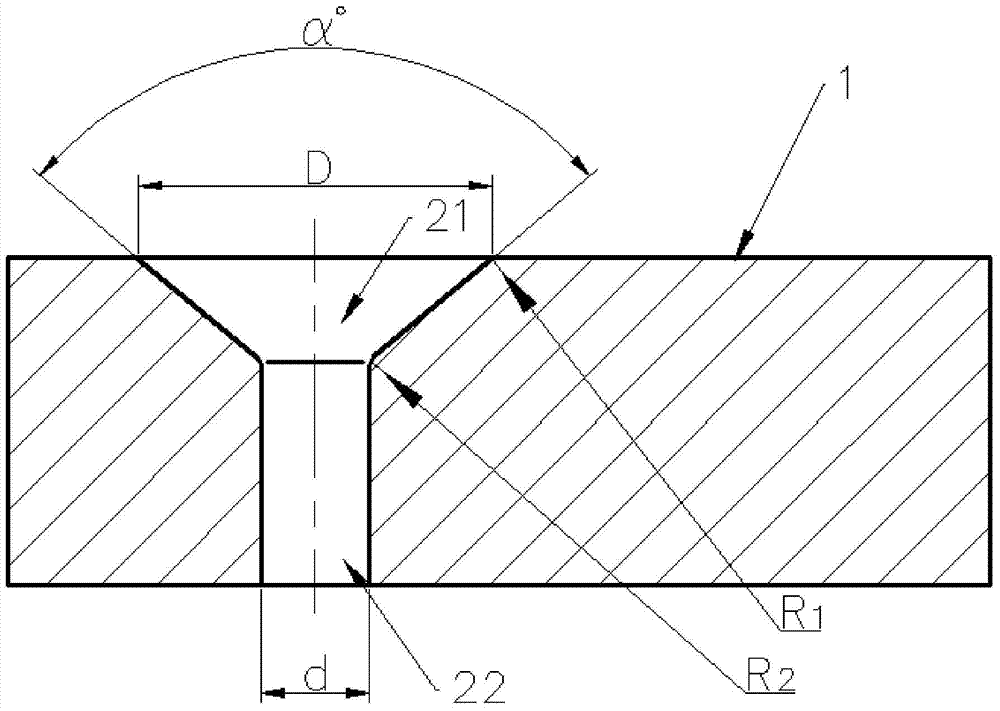

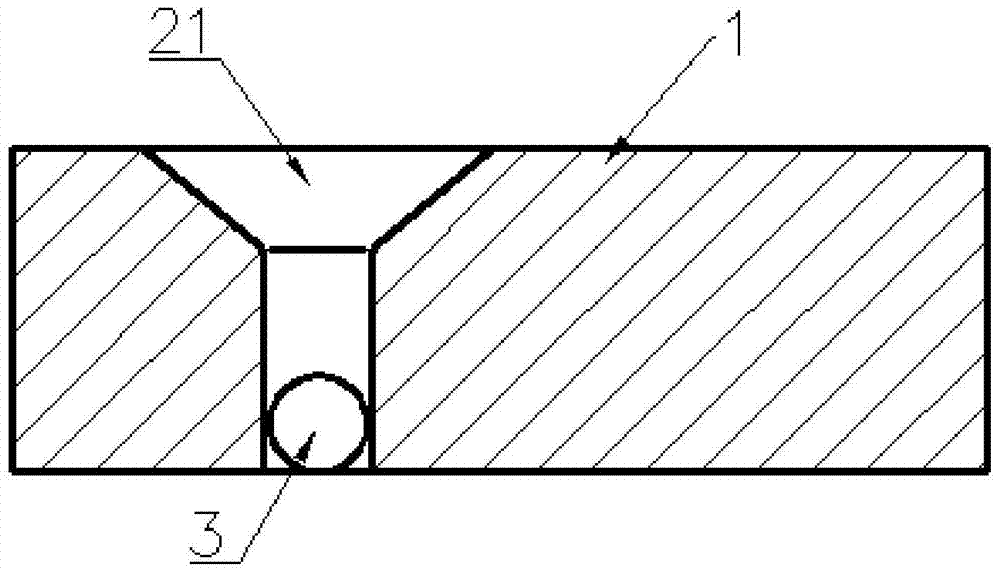

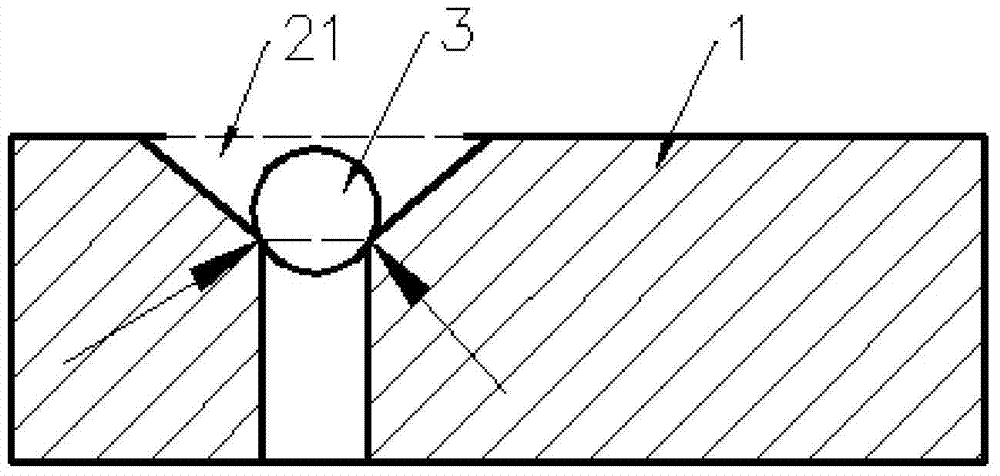

[0054] A double-ball measurement method for counterbore angle, the counterbore to be measured is a conical counterbore, the hole wall of the orifice 21 is conical, and the counterbore orifice 21 and the counterbore orifice 21 are in contact with the counterbore There is a transfer circle at the junction of 22 at the bottom of the hole, and the specific measurement steps are as follows:

[0055] The first step is to prepare the height measuring instrument 4 and a plurality of steel balls 3 with known diameters but different s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com