Unit combined type steam generating device

A steam generating device and combined technology, applied in steam generation, steam generation method, lighting and heating equipment, etc., can solve the problems of large energy waste, safety hazards, low production efficiency, etc., to solve energy waste and improve safety , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

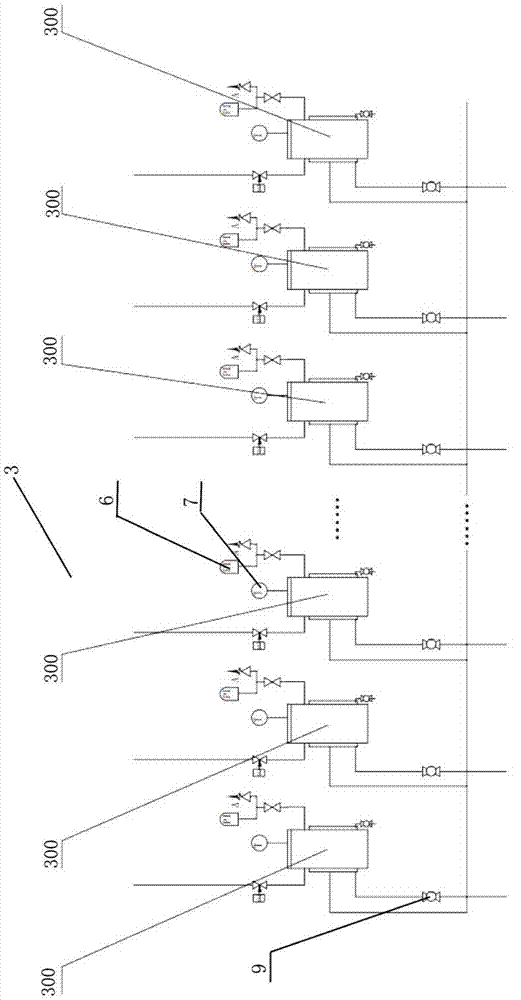

[0032] Such as figure 1 and figure 2 As shown, a unit-combined steam generating device is a mechanical device that uses electric energy to heat water into hot water or steam, and is used for industrial production or heating. Such as figure 1 As shown, the steam generating device includes a water storage tank 1, a water collection distributor 2, a steam generating unit 3, a power distribution cabinet 4, and a control cabinet 5, wherein the water storage tank 1 is connected to the water collection distributor 2 through a regulating valve 10, The water collecting manifold 2 is connected with the steam generating unit 3 through the solenoid valve 9, wherein the steam generating unit 3 is formed by a plurality of steam generating units 300 connected in series or in parallel, and each steam generating unit 300 is controlled by a solenoid valve 9, and the steam generating unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com