Dynamic sealing device

A dynamic sealing and flexible sealing technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problem of difficulty in ensuring relative position, axial displacement, radial displacement caused by the concentricity of the axis and the end surface of the first equipment. Problems such as angular displacement caused by jumping can be eliminated to achieve the effect of improving dynamic sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

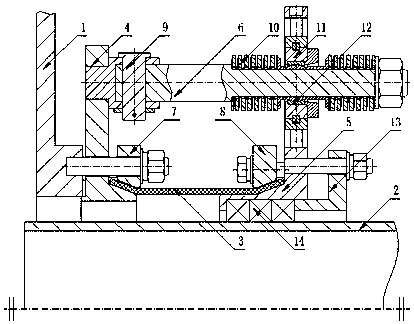

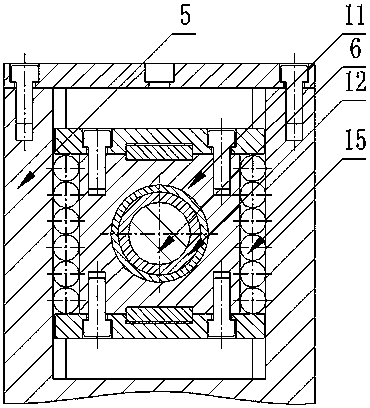

[0024] in, figure 1 is a sectional structure diagram of the dynamic sealing device, figure 2 It is a partial cross-sectional view of the bearing seat in the dynamic sealing device, in figure 1 In the shown structure, the figure only illustrates the structure in which the dynamic sealing device is arranged at one end of the equipment to be sealed.

[0025] The dynamic sealing device seals the medium flow path between the relatively moving first device 1 and the second device 2 . The first device is defined as a dynamic device, and the second device is defined as a static device. The above definition will be further described below.

[0026] The moving equipment rotates at a preset speed along the axis of the static equipment. In order to realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com