Semi-automatic powder filling machine

A filling machine, semi-automatic technology, applied in the direction of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of alignment between empty bottles and quantitative cylinders, difficult cleaning, and empty filling, and achieve easy replacement and cleaning, Easy to operate, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

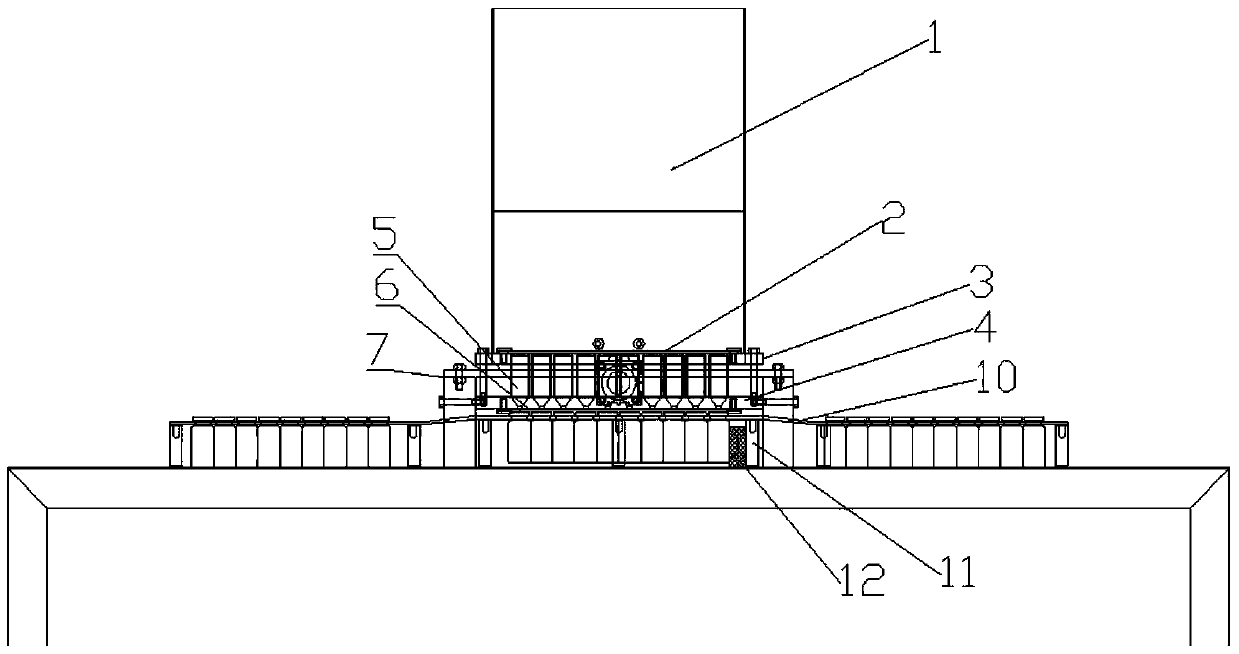

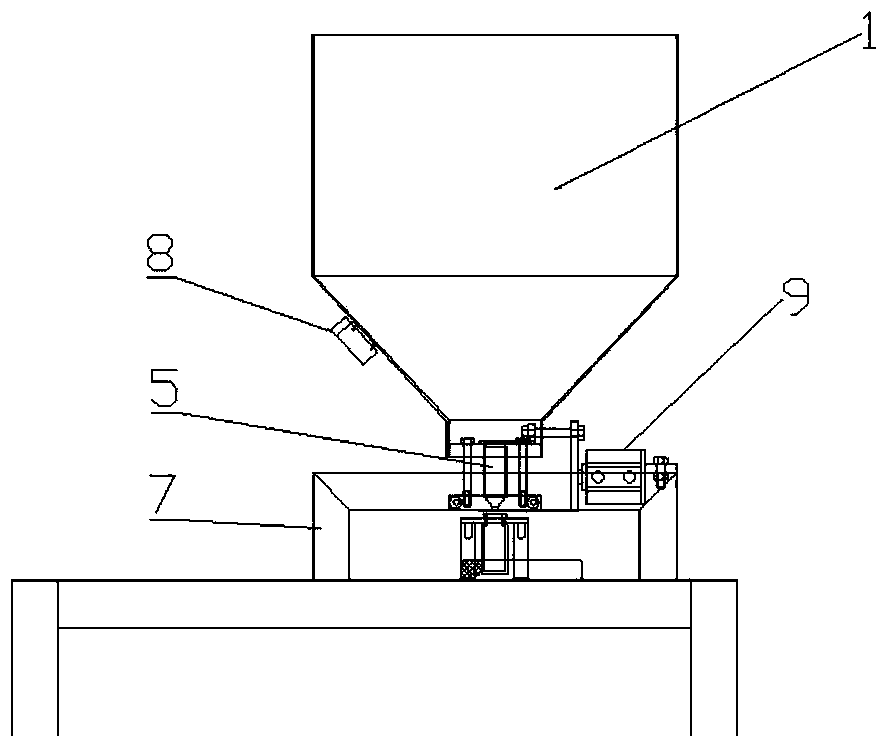

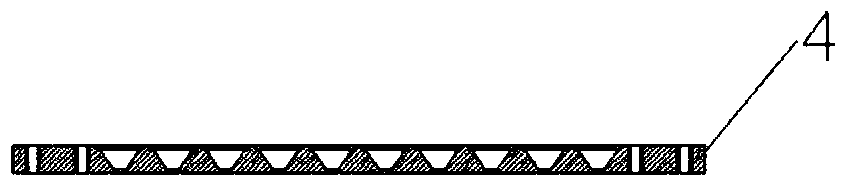

Embodiment 1

[0019] The semi-automatic powder filling machine of this embodiment includes a powder hopper 1, a quantitative device and a working platform, the powder hopper 1 is fixed on the working platform through a fixing frame 7, and the outer bottom of the powder hopper 1 is provided with a pneumatic vibrator 8, Maintain the fluidity of the powder in the powder hopper 1; the quantitative device includes an upper splint 3, a lower splint 4 and a quantitative cylinder 5, the upper splint 3 is fixedly connected with the powder hopper 1, the upper splint 3 is provided with a cylindrical through hole, and the lower splint 4 is provided with a tapered through hole, the quantitative cylinder 5 is fixed between the upper splint 3 and the lower splint 4, and the upper splint 3 and the lower splint 4 are fixed by screws. After opening the screw, it is convenient to clean and replace the quantitative cylinder 5; The upper end is provided with an upper pumping plate valve 2, and the lower end of t...

Embodiment 2

[0022] The semi-automatic powder filling machine of this embodiment is the same as Embodiment 1 except for the following differences:

[0023] A sealing ring is arranged between the quantitative cylinder 5 and the upper splint 3 .

[0024] Both ends of the upper drawer valve 2 and the lower drawer valve 6 are equipped with chute, which cooperate with the limit column on the fixed frame 7, so that the upper drawer valve 2 and the lower drawer valve 6 are driven by the driving cylinder 9. Reciprocating motion along a straight line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com