Special tool for dismounting and mounting linear displacement sensor

A technology of linear displacement and special tools, which is applied in the direction of manufacturing tools and hand-held tools, etc., can solve problems such as unstable sensor detection values, inappropriate tools, and detection data jumps, so as to avoid twisting and cracking of sensor harnesses and highlight substantive features , The effect of solving the disassembly problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

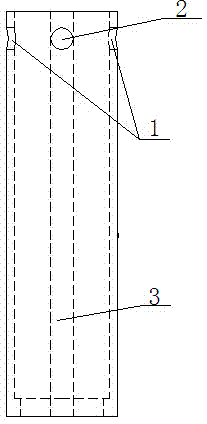

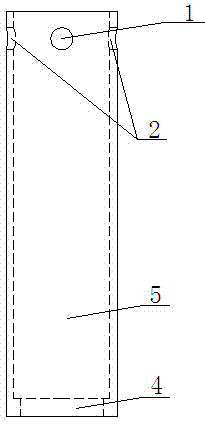

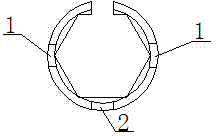

[0021] It can be seen from the accompanying drawings that a special tool for disassembling and assembling a linear displacement sensor includes a sleeve 7 set outside the linear displacement sensor 9, the lower end of the sleeve 7 has a positive hexagonal hole 4 inside, and the inside of the sleeve 7 One side of the regular hexagonal hole 4 is a circular hole with a diameter larger than that of the linear displacement sensor 9 . The diameter of the circumscribed circle of the regular hexagonal hole 4 is greater than the diameter of the circumscribed circle of the hexagonal nut at the head of the linear displacement sensor 9 by 1.8-2.2mm, preferably 2mm, and the length is 11-13mm, preferably 12mm. The regular hexagonal hole 4 of 7 snaps on the hex nut of described linear displacement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circumcircle diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com