Contact element for a plug type connector and arrangement comprising a contact element

A technology of plug-type connectors and contact elements, which is applied to the parts of connection devices, contact parts, fixed/insulated contact members, etc., and can solve the problems of damage to sealing elements, increased materials and expenditures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

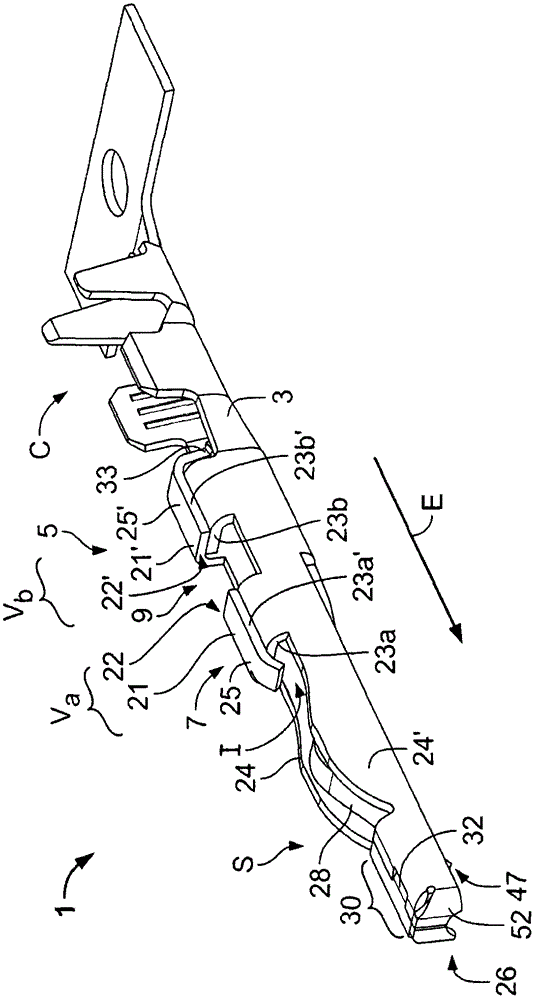

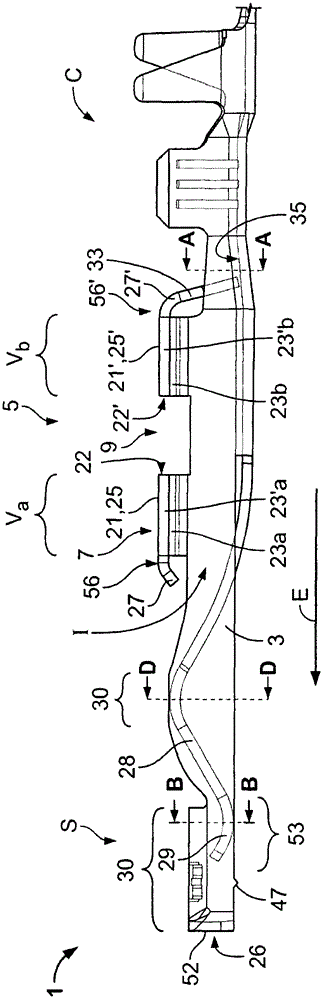

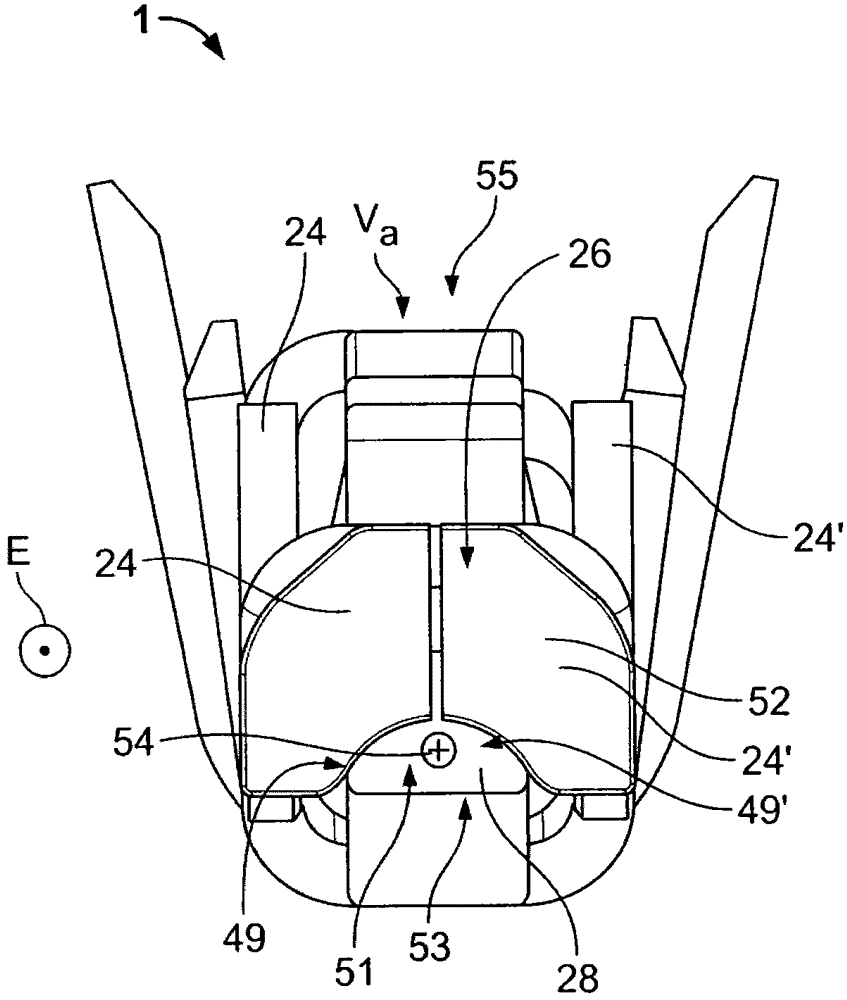

[0053] first refer to attached Figures 1 to 4 The structure of the contact element according to the present invention will be described. refer to Figure 5 , the function of the contact element according to the invention is described in connection with the arrangement according to the invention for electrical contacting.

[0054] figure 1 is a schematic diagram of a contact element 1 according to the invention and figure 2 is a longitudinal section view. The contact element 1 is formed from an electrically conductive contact material 3 as a single bent / punched part. The body 5 of the contact element 1 extends in the insertion direction E. As shown in FIG. At the end oriented in the direction of insertion E, the contact element 1 has an end region S with an end 26 and at its end oriented in the direction opposite to the direction of insertion E has a crimped region C .

[0055] The body 5 has a catch opening 9 at its upper side 7 . The catch opening 9 is delimited by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com