A dynamic detection device and implementation method for shape and position parameters of elevator guide rails

A technology for elevator guide rails and dynamic detection, applied in the direction of measuring devices, electrical devices, optical devices, etc., can solve problems such as poor stability and large data errors, and meet the requirements of detection accuracy, clear circuit connection relationship, and mechanical structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

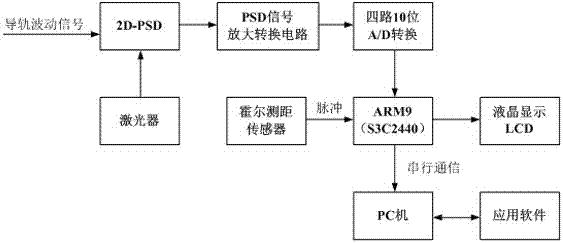

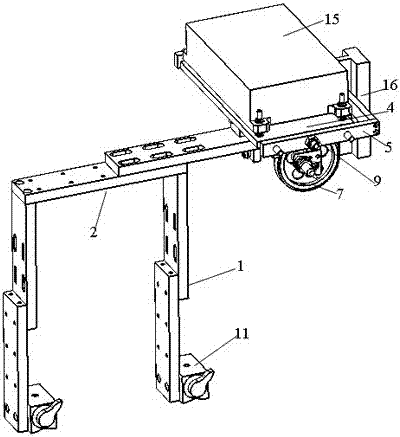

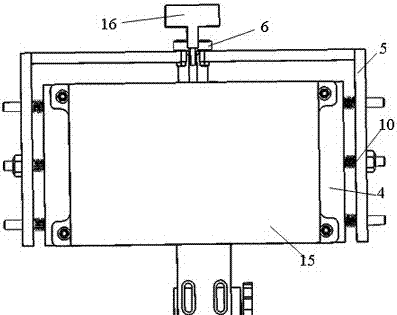

[0022] refer to Figure 1 to Figure 4 , the present invention relates to a dynamic detection device for shape and position parameters of an elevator guide rail, comprising a detector and a mechanical fixing bracket for installing the detector on the elevator guide rail, the hardware of the detector includes a laser, a two-dimensional position sensitive device (2D -PSD), PSD signal amplification conversion circuit, A / D conversion module, Hall ranging sensor, ARM9 chip, liquid crystal display LCD and PC, the laser is connected to the PSD signal amplification conversion circuit through a two-dimensional position sensitive device, Described PSD signal amplifying conversion circuit is connected with ARM9 chip circuit through A / D conversion module, and described ARM9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com