Transport forklift

A technology of forklifts and fork claws, which is applied in the field of transport forklifts. It can solve the problems of forklifts with large fork claws that are not suitable for moving and turning in logistics yards, increasing costs, and unfavorable forklift pallet recycling, so as to improve rigidity and reduce forklifts. The effect of claw length and flexible steering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

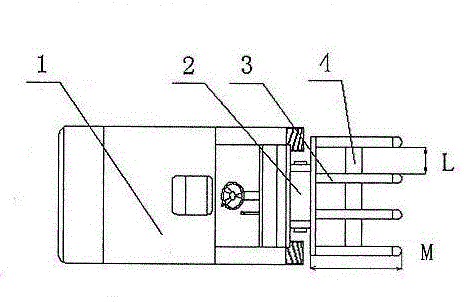

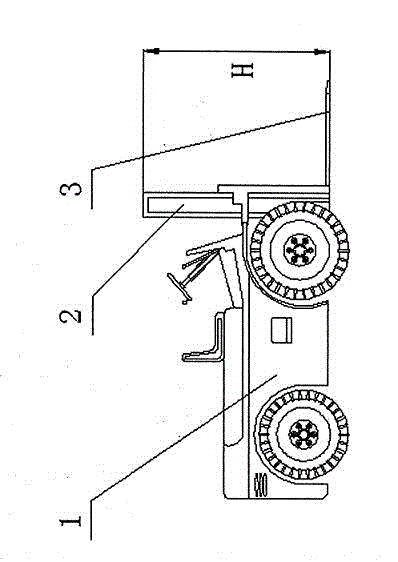

[0012] A transport forklift, comprising a car body 1, a lifting mechanism 2, and fork claws 3, the number of the fork claws 3 is at least four, and reinforcing ribs 4 are connected between the fork claws 3, and the gap between the fork claws 3 The spacing L is 20-50cm, and the goods can just be coded on the claws 3 without falling. Then the height H of the lifting mechanism 2 is controlled at 1.8-2.5m, which is basically the same as the height of the semi-trailer transport vehicle to facilitate cargo transfer. When in use, the driver directly lowers the height of the fork claw 3 through the lifting mechanism 2, so that the fork claw 3 is close to the ground, directly scoops up the goods, puts the goods on the fork claw 3, directly transfers the goods and loads them, and pulls back the fork claw 3 That is, the pallet is no longer used, which greatly shortens the handling time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com