Anti-twist installation method for underwater structures in deep water

A technology of underwater structure and installation method, which is applied to the installation of deep-water underwater structures and anti-rotation installation of deep-water underwater structures, and can solve the problems of easy occurrence, easy torsion, unfavorable control of horizontal azimuth accuracy, etc. Achieve the effect of saving installation cost, improving installation accuracy and saving offshore operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

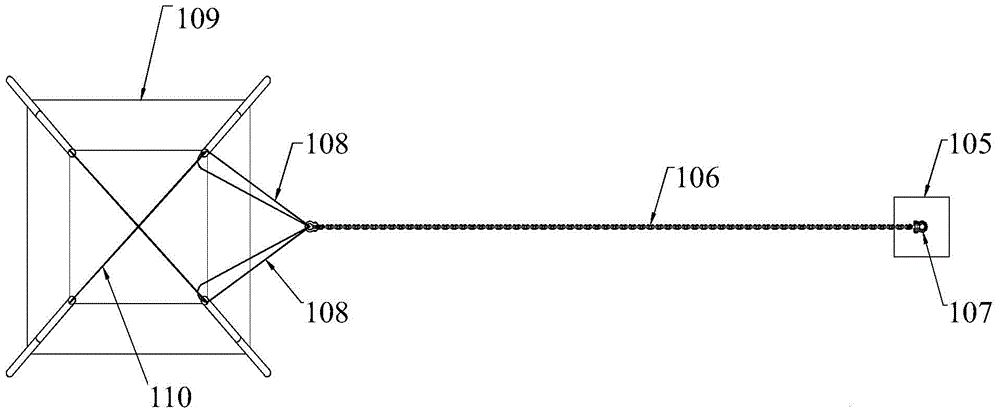

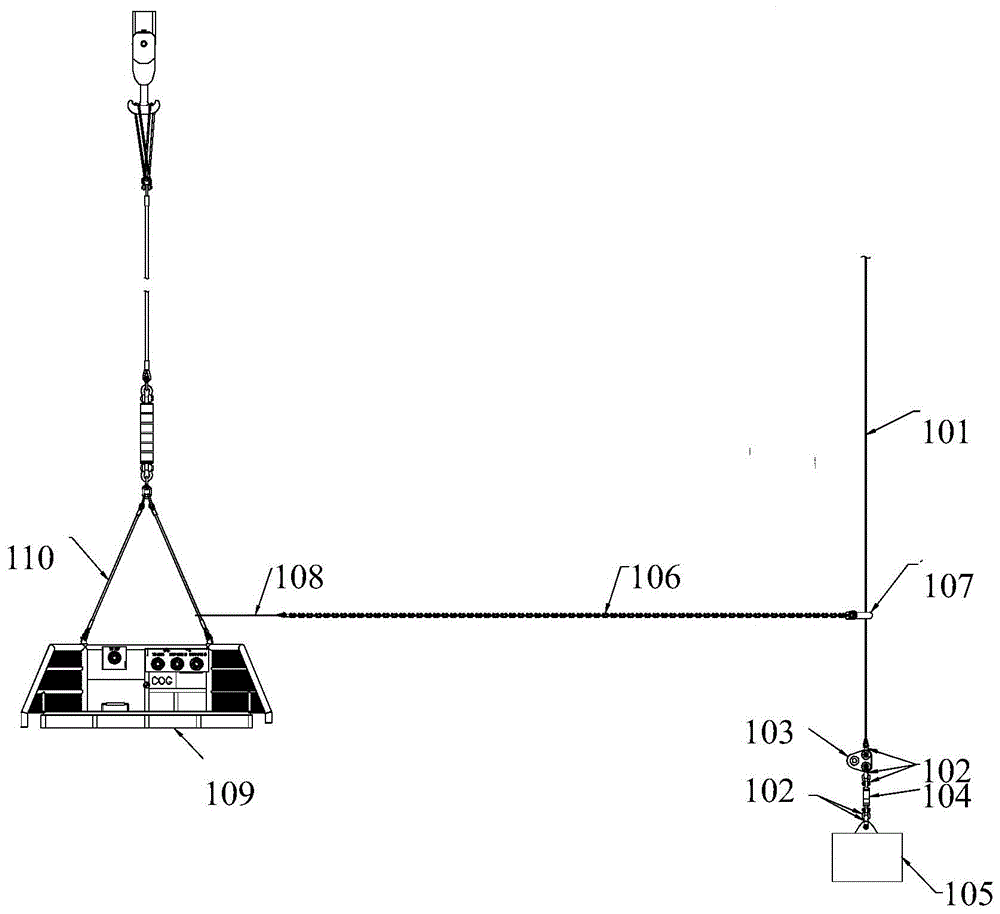

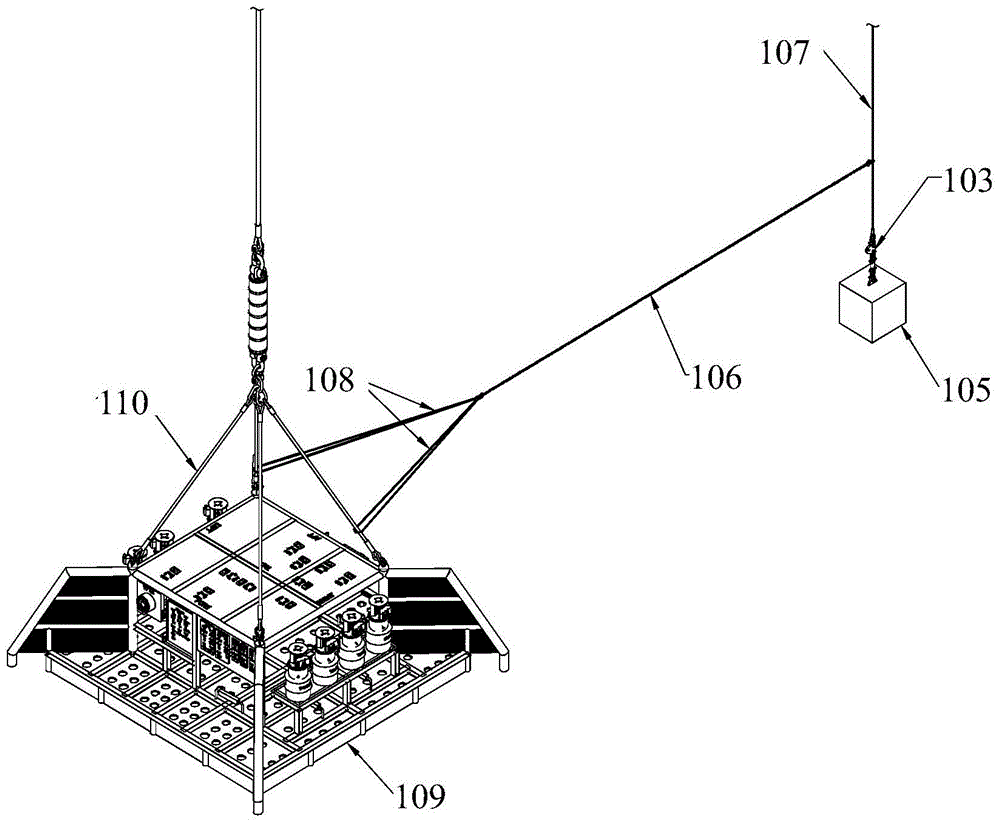

[0047] Such as Figure 1-Figure 5 As shown, the present invention includes: a structural weight 105 for producing vertical force, a winch guide cable 101 vertically suspended on the structural weight 105, wherein the winch guide cable 101 passes through a sliding snap ring 107 and a horizontal One end of the traction cable 106 is set, and the other end of the horizontal traction cable 106 is respectively connected with the hoisting sling 110 installed on the deep-water underwater structure 109 or the deep-water underwater structure 109 through two short cables 108, forming a triangular shape. state.

[0048] The above-mentioned winch guide cable 101 and the structural weight 105 are connected as a whole through a connecting structure, and the connecting structure includes: a rotary joint 104 installed on the first shackle 102, a triangular plate 103, and a second shackle 102, Wherein, the swivel joint 104 is used to separate the relative twist between the deep-water underwate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com