A coke oven flue gas desulfurization and denitrification process

A coke oven flue and waste gas desulfurization technology, which is applied in coke ovens, coke oven heating, combustible gas heating coke ovens, etc., can solve the problems of secondary pollution, high energy consumption, and high operating costs, so as to prolong the service life, Energy saving and investment reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

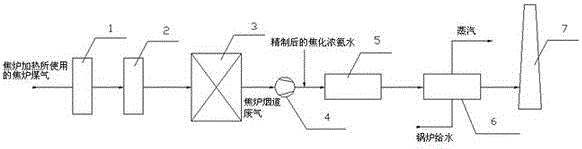

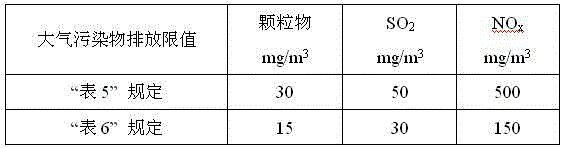

[0051] A coke oven flue gas desulfurization and denitrification process. The coke oven gas used for heating the coke oven is first used to remove sulfur compounds and impurities by a dry desulfurization process in which a desulfurization tower and an adsorption tower are connected in series to obtain purified coke oven gas. The coke oven flue gas produced by the combustion in the coke oven is under the action of the low-temperature SCR denitrification catalyst, and the nitrogen oxides in the flue gas are removed through the SCR reaction and then discharged up to the standard. The exhaust flue gas reaches the highest standard specified in GB16171-2012.

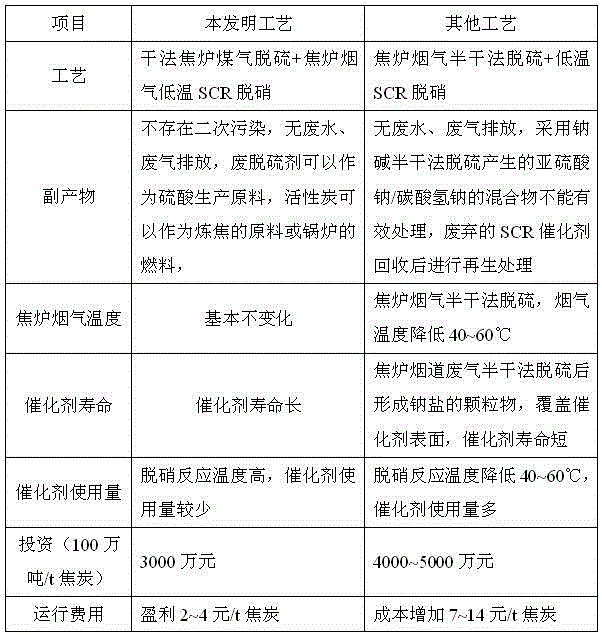

[0052] The present invention adopts a dry coke oven gas desulfurization + coke oven flue gas low-temperature SCR denitrification process. The prior art generally adopts a coke oven flue gas semi-dry desulfurization + low-temperature SCR denitrification process. The specific comparison is shown in Table 2:

[0053] Table 2. Compariso...

Embodiment 2

[0056] A coke oven flue gas desulfurization and denitrification process. The coke oven gas used for heating the coke oven is first used to remove sulfur compounds and impurities by a dry desulfurization process in which a desulfurization tower and an adsorption tower are connected in series to obtain purified coke oven gas. The coke oven flue gas produced by the combustion in the coke oven is under the action of the low-temperature SCR denitrification catalyst, and the nitrogen oxides in the flue gas are removed through the SCR reaction and then discharged up to the standard. The exhaust flue gas reaches the highest standard specified in GB16171-2012.

[0057] The total sulfur content of the purified coke oven gas is 30mg / m 3 .

[0058] The dry desulfurization process of the present invention is a conventional coke oven gas dry desulfurization process:

[0059] The desulfurizing agent in the desulfurization tower is iron oxide, and the desulfurizing agent is regularly replaced after...

Embodiment 3

[0062] A coke oven flue gas desulfurization and denitrification process. The coke oven gas used for heating the coke oven is first used to remove sulfur compounds and impurities by a dry desulfurization process in which a desulfurization tower and an adsorption tower are connected in series to obtain purified coke oven gas. The coke oven flue gas produced by the combustion in the coke oven is under the action of the low-temperature SCR denitrification catalyst, and the nitrogen oxides in the flue gas are removed through the SCR reaction and then discharged up to the standard. The exhaust flue gas reaches the highest standard specified in GB16171-2012.

[0063] The total sulfur content of the purified coke oven gas is 35mg / m 3 .

[0064] The temperature range of the low-temperature SCR denitration catalyst is 160°C to 290°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com