Vegetable cleaning device

A technology for cleaning devices and vegetables, applied in the fields of application, food processing, food science, etc., can solve the problems of insufficient contact area, waste of labor resources, and inability to remove dirt, etc., to increase the contact area, reduce labor intensity, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

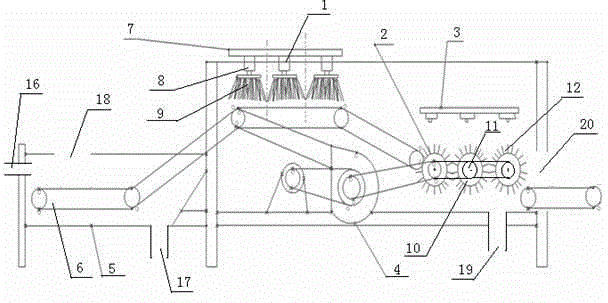

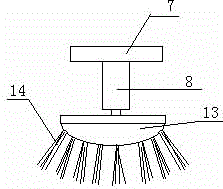

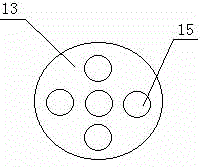

[0022] Such as figure 1 , figure 2 As shown, a vegetable cleaning device is composed of a first cleaning brush 1, a second cleaning brush 2, a high-pressure nozzle 3, a motor 4, a washing tank 5, and a conveyor belt 6. The first cleaning brush 1 includes a fixed frame 7, a telescopic Shaft 8 and disc brush 9, the fixed frame 7 is fixedly mounted on the top of the device, one end of the telescopic shaft 8 is fixedly mounted on the fixed frame 7, and the other end is connected to the disc brush 9; the second cleaning brush 2 includes a sleeve 10 , a rotating shaft 11 and bristles 12, the rotating shaft 11 fixedly connected to the side of the device at one end is built into the sleeve 10, and the other end of the rotating shaft 11 is connected to the motor 4, and the bristles 12 are arranged in the sleeve 10 in a helical shape Above; the high-pressure nozzle 3 is fixedly installed above the second cleaning brush 2; the motor 4 is connected to the conveyor belt 6; the disc brush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com