Petroleum trial-production regulating system

An adjustment system and trial mining technology, which is applied in the direction of control/regulation system, general control system, mining fluid, etc., to achieve the effect of increasing coordination and linkage, improving safety and explosion-proof level, and controlling accident rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

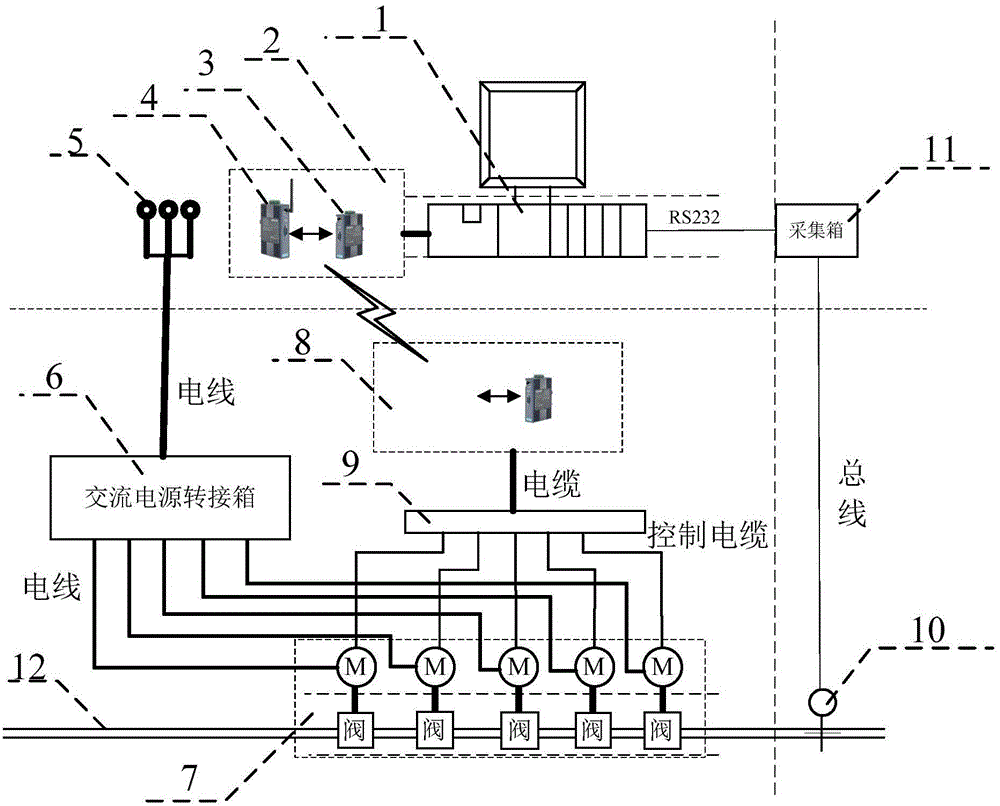

[0016] Below in conjunction with accompanying drawing, invention is described in further detail.

[0017] like figure 1 As shown, the oil test production adjustment system of the present invention includes a central control terminal 10 and a test production site control terminal 20 . Among them, the test mining site control terminal 20 is set in the test mining site, the central control terminal 10 is set in the remote, and the control device 1 and the central control terminal communication device 2 are set in the central control terminal 10. The on-site acquisition parameters collected by the on-site control terminal 20 include: flow rate and pressure parameters, and generate on-site control instructions. The instructions mainly include valve opening information such as 0%, 25%, and 100%. The on-site parameter acquisition device includes a flow sensor and a pressure sensor, and the flow sensor and the pressure sensor are connected to the main acquisition line at the trial mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com