Coal mine air inlet wellhead temperature adjusting system

A technology of temperature adjustment system and air inlet, which is applied in heating and ventilation control system, heating and ventilation safety system, ventilation of mine/tunnel, etc., and can solve problems such as energy waste, increased environmental pollution, and large energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

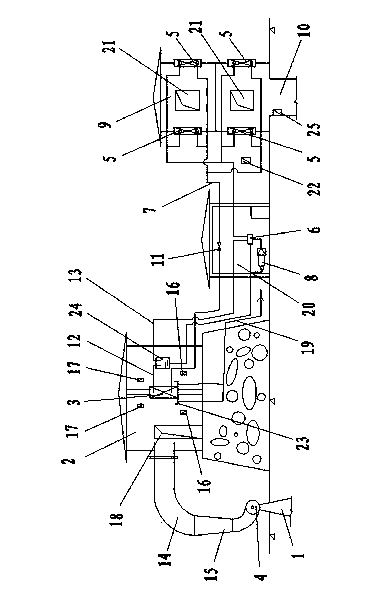

[0016] see figure 1 , the coal mine air inlet wellhead temperature adjustment system of the present invention comprises a exhaust air heat exchange chamber 2, an exhaust air heat exchange chamber 2 is provided with an exhaust air heat exchanger 3, and the air inlet of the exhaust air heat exchange chamber 2 is provided with a return air The air duct of the fan 4 is connected to the outlet of the mine return air main road 1, the air outlet of the exhaust air heat exchange chamber 2 is communicated with the outside world, and the outlet of the heat exchange pipeline of the exhaust air heat exchanger 3 is connected to the four-way valve 6 through the conveying pipeline. The inlet of the heat exchange pipeline of the exhaust air heat exchanger 3 is connected to the outlet of the heat exchange pipeline of more than one air heat exchanger 5 through the connecting pipeline 7, and the connecting pipeline 7 is connected in series with expansion valve 11. The inlet of the heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com