Electric valve

A technology of electric valves and valve ports, which is applied to valve devices, valve details, engine components, etc., and can solve problems such as inconstant volume, uncertain direction, harsh sound, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

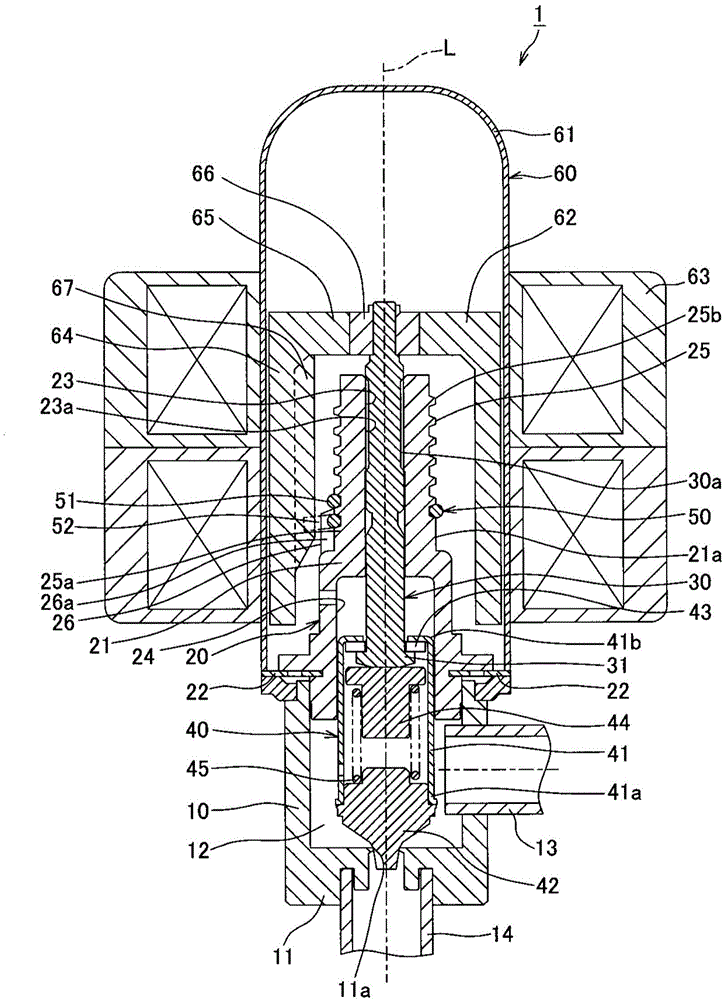

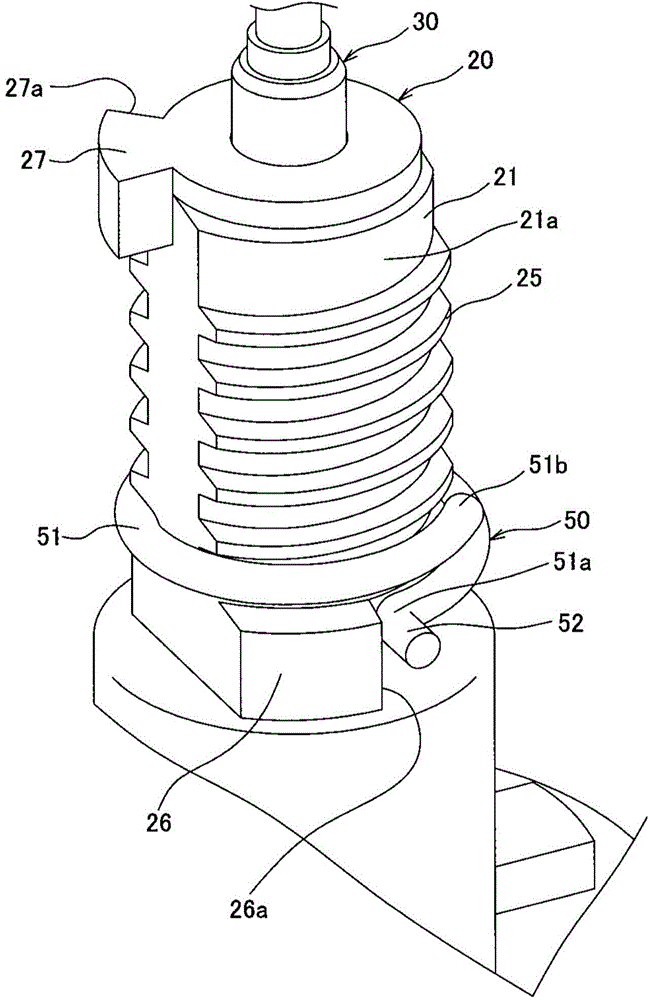

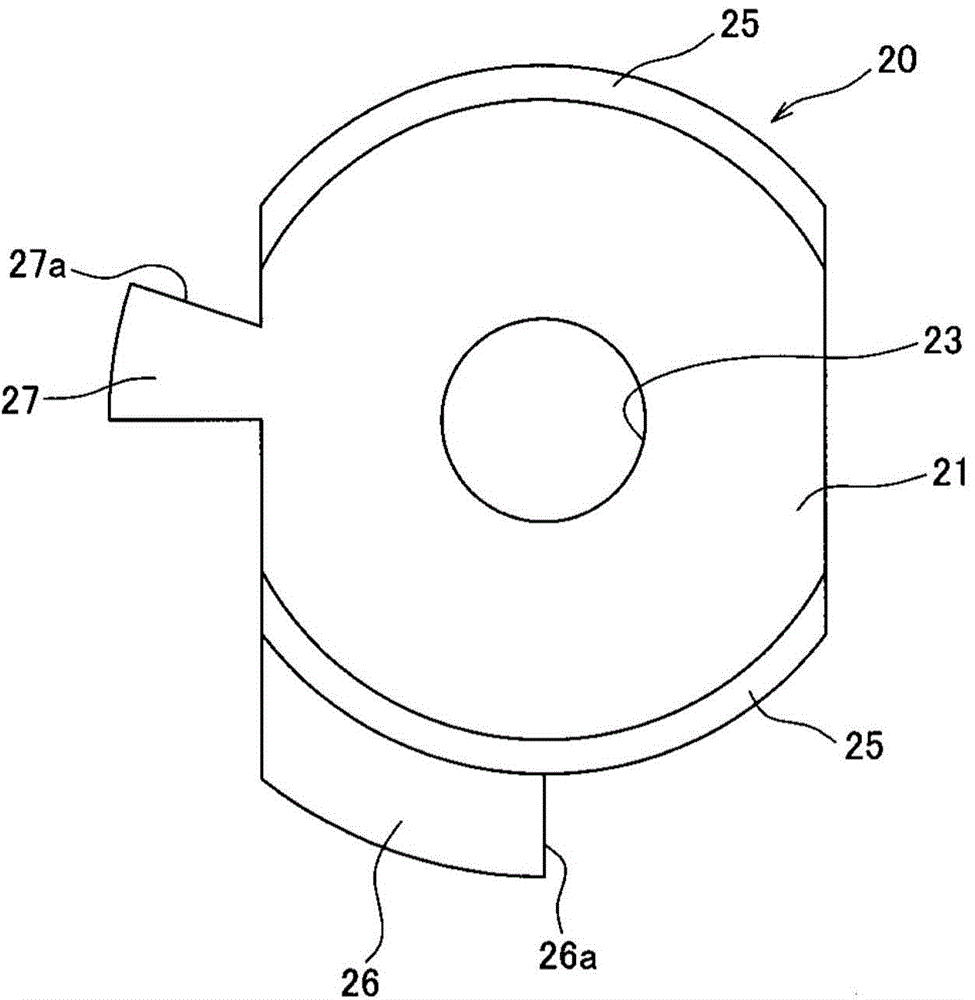

[0044] Below, refer to Figure 1 to Figure 7 An electric valve according to a first embodiment of the present invention will be described.

[0045] figure 1 It is a longitudinal sectional view seen from the front direction of the electric valve which concerns on 1st Embodiment of this invention. figure 2 yes figure 1 A perspective view of the supporting member and coil member of the electric valve. image 3 yes figure 2 A top view of the support components. Figure 4 yes figure 2 A perspective view of the coil assembly. Figure 5 yes figure 1 A vertical cross-sectional view of the magnetic rotor included in the electric valve. Figure 6 yes Figure 5 Cutaway perspective view of the magnetic rotor. Figure 7 It is a figure showing the state where the claw part of the coil part hits the valve closing stopper protrusion of the support part, Figure 7 (a) is a figure seen from the back direction, Figure 7 (b) is a figure seen from the side direction. In additio...

no. 2 approach

[0082] Below, refer to Figure 8 ~ Figure 10 An electric valve according to a second embodiment of the present invention will be described.

[0083] Figure 8 It is a longitudinal sectional view seen from the front direction of the electric valve concerning 2nd Embodiment of this invention. Figure 9 yes Figure 8 A perspective view of the coil part included in the electric valve. Figure 10 It means that the claw part of the coil part touches the Figure 8 The diagram of the state of the limit wire body of the guide part of the electric valve, Figure 10 (a) is a figure seen from the front direction, Figure 10 (b) is a figure seen from the side direction. In addition, concepts such as "up and down" in the following descriptions indicate directions and Figure 8 The directions correspond to each other, and represent the relative positional relationship of each component, not the absolute positional relationship.

[0084] Such as Figure 8 As shown, this electric valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com