Chain and chain guide plate

A chain and plate technology, applied in the direction of belts/chains/gears, chain elements, transmission chains, etc., can solve problems such as noise, and achieve the effects of avoiding the increase in the number of blocks, suppressing noise, and improving contact balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

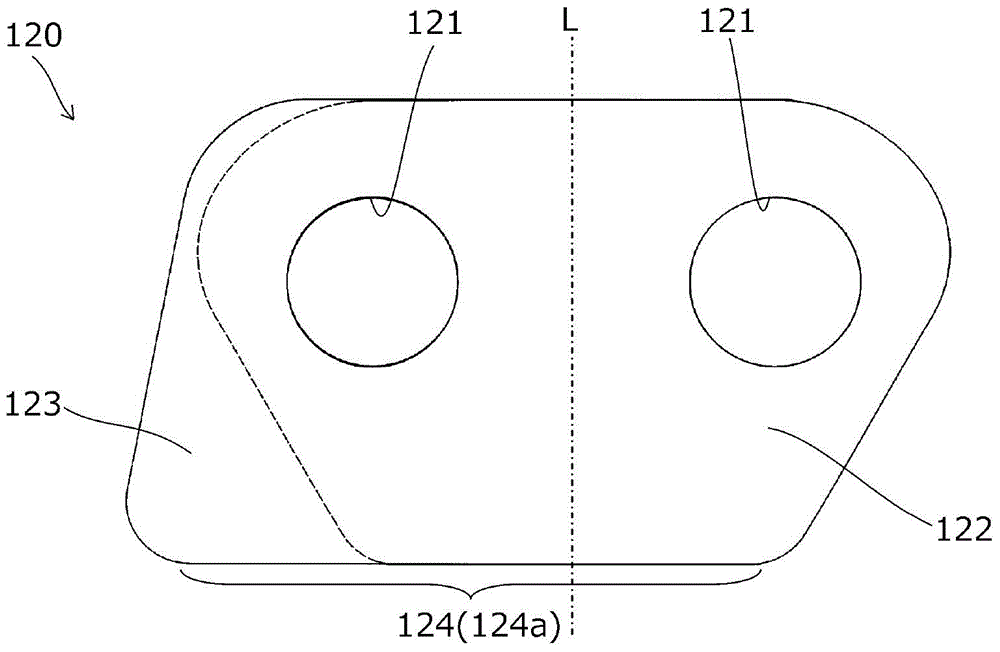

[0031] Below, according to Figure 1~4 The chain 100 which concerns on 1st Embodiment of this invention is demonstrated.

[0032] The chain 100 of the first embodiment is configured as a timing chain installed in a timing system for an automobile engine, as figure 2 As shown, the chain moves on a predetermined track in a state where it is wound on a plurality of sprockets (not shown) and the inner guide G having a flat guide block surface G1 guides the curved inner peripheral side of the chain. . The inner guide G is configured as a fixed guide fixed to a peripheral portion such as an engine block or as a swing guide that is pressed toward the chain 100 side by a tensioner swingably attached to the peripheral portion.

[0033] Such as figure 1 As shown in the chain 100 , a plurality of first plate arrays 110 and a plurality of second plate arrays 140 are alternately arranged and flexibly connected in the chain length direction by half a pitch.

[0034] Such as figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com