a vibration isolation ditch

A vibration isolation and ditch technology, which is applied in protection devices, buildings, infrastructure engineering, etc., can solve the problems that the vibration isolation ditch cannot bear the load and cannot be installed under the road, and achieve the effect of reducing the transmission of vibration waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

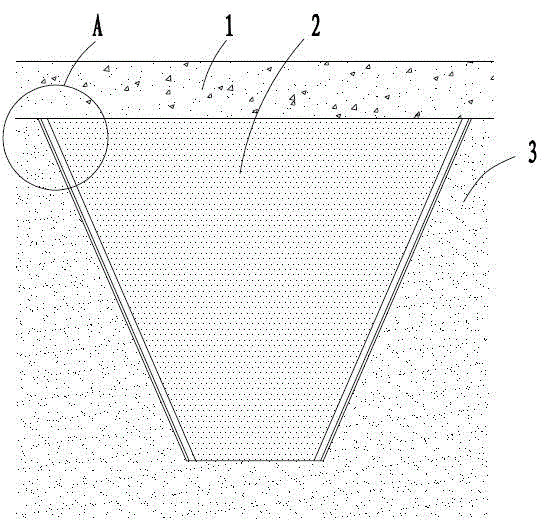

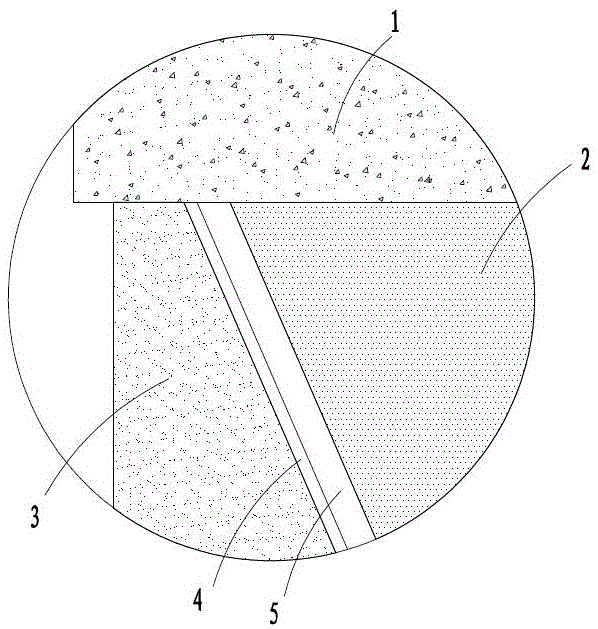

[0024] Embodiment 1: A kind of vibration isolation ditch, such as figure 1 , 2 shown. In this structure, a trapezoidal ditch with a trapezoidal interface is dug in the plain soil layer 3 of the subgrade. The ditch body is wide at the top and narrow at the bottom. The two side walls of the ditch body are successively laid with polystyrene boards 4 with a thickness of 40mm and reinforced concrete boards with a thickness of 100mm from bottom to top. Inside the ditch is a sand and gravel filling layer 2, which is flush with the ditch mouth. Concrete pavement 1 is poured above the ditch body, and the width of the concrete pavement is greater than the width of the ditch body.

Embodiment 2

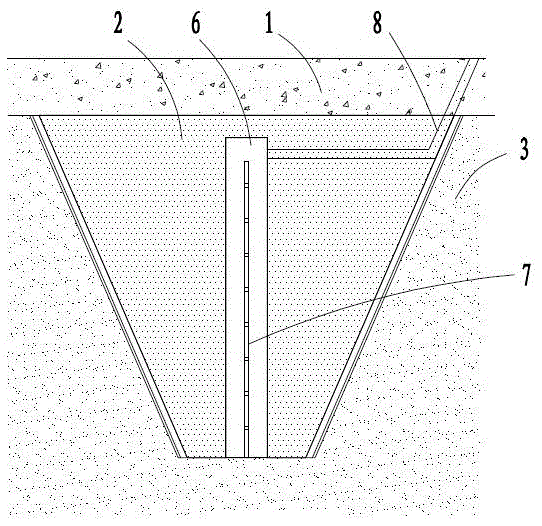

[0025] Embodiment 2: A kind of vibration isolation ditch with vibration isolation water tank, such as image 3 shown. In this structure, a trapezoidal ditch with a trapezoidal interface is dug in the plain soil layer 3 of the subgrade. The ditch body is wide at the top and narrow at the bottom. The two side walls of the ditch body are successively laid with polystyrene boards 4 with a thickness of 40mm and reinforced concrete boards with a thickness of 100mm from bottom to top. Inside the ditch is a sand and gravel filling layer 2, which is flush with the ditch mouth. Concrete pavement 1 is poured above the ditch body, and the width of the concrete pavement is greater than the width of the ditch body.

[0026] A vibration-isolation water tank 6 is buried in the sand-stone filling layer 2. The bottom of the vibration-isolation water tank is arranged on the bottom surface of the ditch body. The top of the vibration-isolation water tank does not exceed the top surface of the sa...

Embodiment 3

[0028] Embodiment 3: A kind of vibration isolation ditch with double clapboard vibration isolation water tank, such as image 3 shown. Two partitions 7 are arranged in parallel in the vibration-isolation water tank 6 of this structure, and the damping holes of the two partitions are mutually misaligned. The rest of the structure of this embodiment is the same as that of Embodiment 2. Utilizing the misalignment of the vibration-damping holes of the two partitions, a complex shearing action is formed at the vibration position of the water body to achieve the effect of rapidly absorbing the vibration energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com