A large mesh device for a textile machine

A technology of large mesh and textile machine, used in textile and paper making, knotting, netting, knotting, etc., can solve the problems of increasing the stroke of the rolling net cam and not being able to weave larger, and achieve accurate and economical processing. The effect of improving the level and overcoming the machining error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

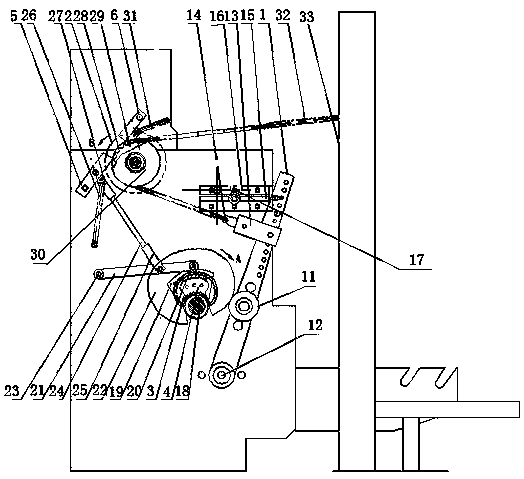

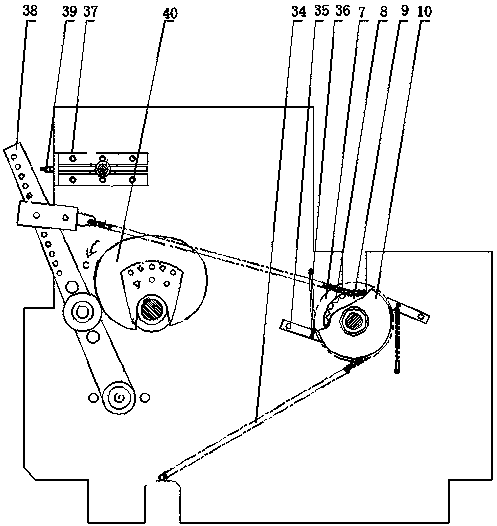

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] A large-mesh device for a textile machine, comprising a let-off swing arm 1, a main let-off roller 2, and a gate opening cam 3, a gate opening cam 3 is provided on one side of the warp let-off swing arm 1, and a gate opening cam 3 is provided at the bottom of the gate opening cam 3 The cam seat 4, the main let-off roller 2 is arranged above the opening cam 3, the opening wedge 5 is arranged beside the main let-off roller 2, the main let-off wedge 6 is arranged beside the opening wedge 5, and the let-off swing arm The other side of 1 is provided with the main roll net roll 7, and the main roll net roll 7 is provided with the anti-retreat sheave-8, and the back-stop sheave-8 is provided with the sprocket wheel-9, and the main volume net roll 7 is provided with Roll net clutch 10, the warp let-off swing arm 1 is provided with installation round holes, the installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com