Novel PCCP steel barrel hanger and PCCP steel barrel hoisting method

A steel cylinder and spreader technology, which is applied in the field of a new type of PCCP steel cylinder spreader and PCCP steel cylinder hoisting, can solve the problems of potential safety hazards, slow lifting speed, and damage to the socket ring of the steel cylinder, so as to reduce potential safety hazards, The effect of ensuring quality and speeding up the lifting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

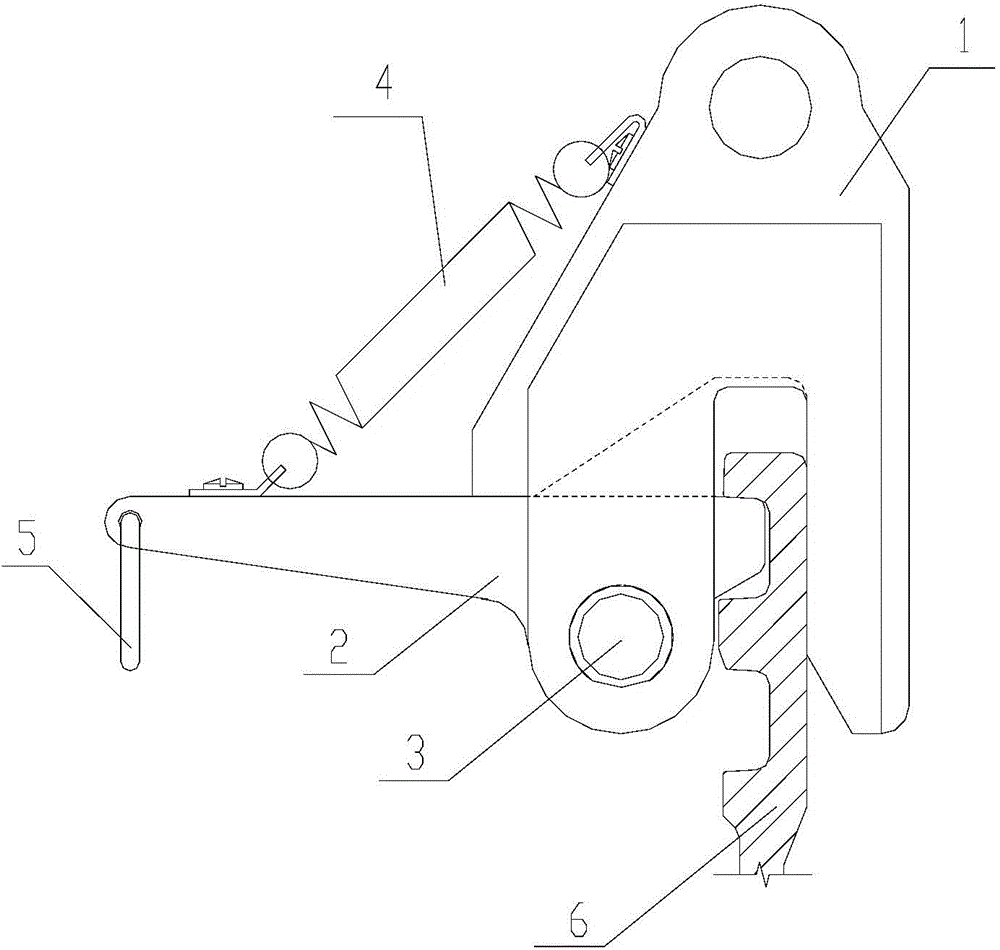

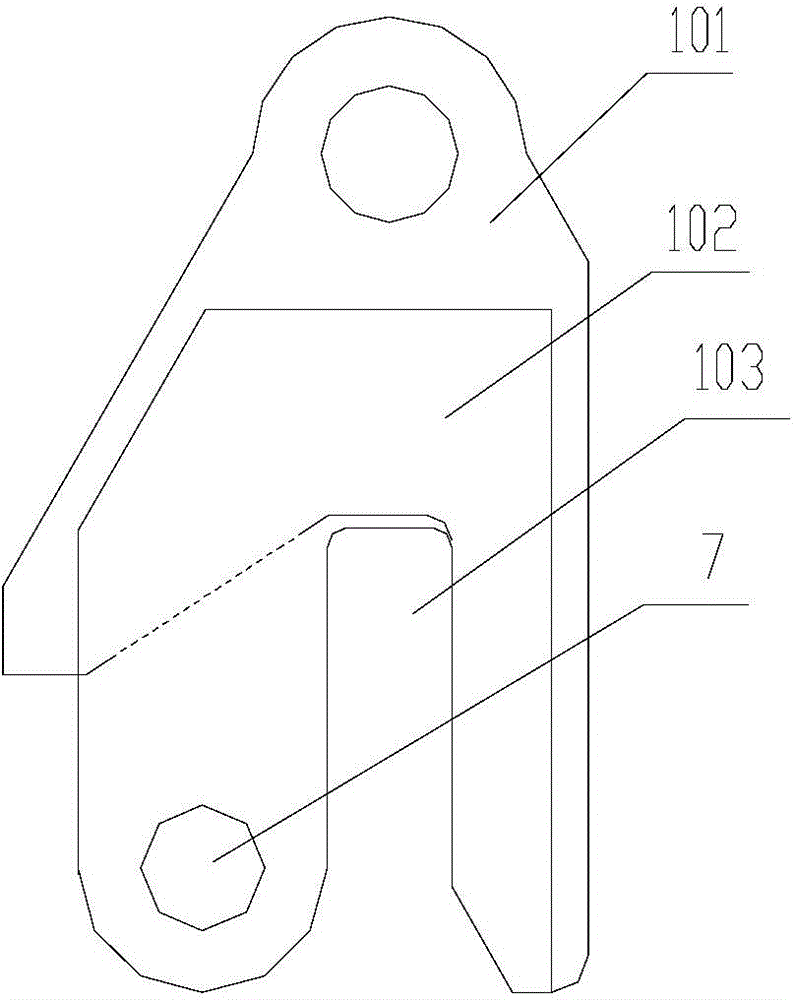

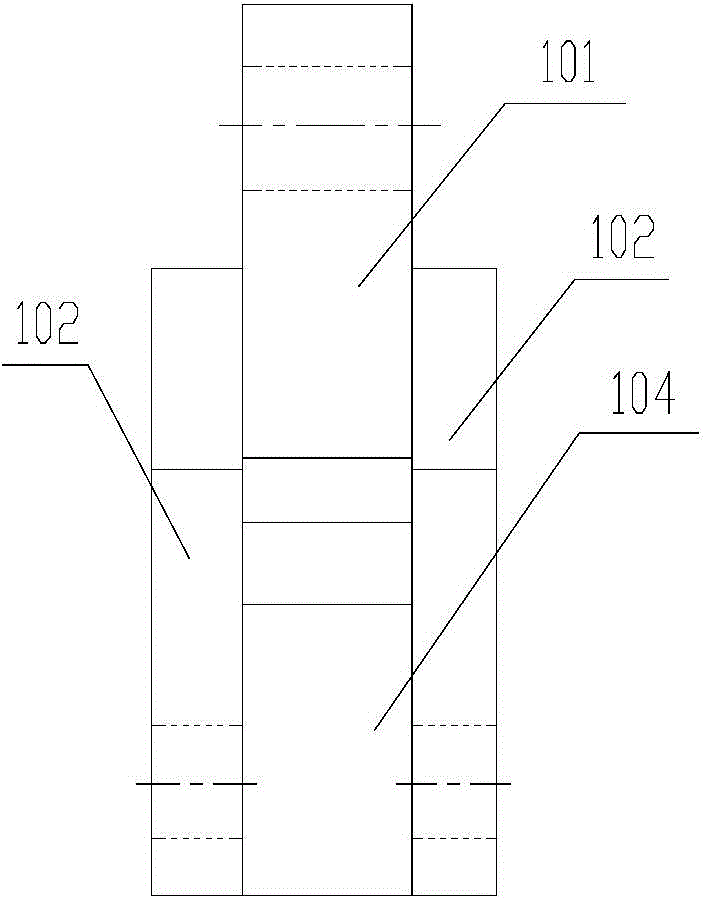

[0023] see figure 1 , a new type of PCCP steel cylinder spreader, including a C-type elevator 1, the opening of the C-type elevator 1 is facing downward, and a card slot 103 is formed at the opening, and a limiting groove 104 is provided on the left side of the C-type elevator 1 to limit The top surface of the position groove 104 is an inclined plane inclined from top to bottom, and a horizontal plane is provided between the inclined surface and the left side, and the limit block 2 is connected by the pin shaft 3 between the two side walls of the limit groove 104, and the limit block 2 is connected with a tension spring 4 at the front end of the horizontal surface of the top surface, and the other end of the tension spring 4 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com